GPMFG

Custom Metal Parts & Die casting Manufacturer in China.

End-to-end die casting including superior mold design, precision zinc/aluminum/magnesium casting, and comprehensive finishing.

- Mold Design & Manufacturing

- Aluminum & Zinc Die-casting

- CNC Machining & Stamping

- Full Post Processes

- Diverse Color Suface Finish available

- No MOQ

solution

From Development To Production

- Products/Parts Analysis.Issue DFM

- Tooling/Molds design

- Publish In-house 2D product drawing with Tolerance

- Publish SOP,SIP,BOM

- Check and accept Tooling/Molds and fixtures

- Trial production and make samples

- Test Products

Facilitate On-Demand Manufacturing for Quicker and Simpler Results.

Tell Us What You Need

Tell us as specific as possible of your needs, provide the drawing, reference picture and share your idea.

Get Solution & Quote

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 12 hours.

Approve for Mass Production

We will start mass production after getting your approval and deposit, and we will handle the shipment.

Jacob Deng

- jacob@gainpower-mfg.com

- +86 137 1306 1055

Gallery

Automotive

Engine blocks

clutches

wheel rims

gearbox cases

steering components

suspension parts

Aerospace

Aircraft fittings

engine mounts

rotor parts

landing gear

doors

drone bodies

Electronics Enclosures

heat sinks

EMI shields

brackets

gears

device frames

Industrial

Pump housings

machine bases

motor mounts

valve bodies

caster wheels

conveyor rollers

Medical

Orthopedic implants

prosthetics

pill casings

instrument bodies

device housings

surgical tools

Defense

Vehicle/aviation components

body armor

drone frames

weapon parts

optical devices

tactical equipment

Electrical

Transformer casings

fuse boxes

capacitor housings

switch boxes

relay cases

busbar holders

Consumer Products

Power tool housings

padlock cases

appliance bodies

flashlight components

zippers

plumbing fixtures

Telecommunications

Equipment chassis

switch housings

brackets

heat sinks

antenna mounts

waveguides

HVAC

Heat exchangers

vent covers

valve parts

radiator mounts

unit brackets

ducting

FULL-SERVICE

Die Casting Service

Our capabilities include manufacturing solutions for a variety of product sizes utilizing both hot and cold pressing. Our process allows for wall thicknesses as thin as 0.38mm, providing excellent dimensional accuracy and a surface finish of 0.8-3.2um Ra due to high pressures employed during the casting process.

- 24 Die-Casting Machines,50-800T

- Die-Casting Weight:From 5g to 8.6kg

- Die-Casting Material: Aluminum Alloy, Zinc Alloy,Magnesium Alloy

- Working Time: 3 shifts 24 hours

Stamping Service

Our capabilities include manufacturing solutions for parts from 0.5mm to 6.5mm thickness using progressive dies on stamping presses from 10 to 200 metric tons. Excellent dimensional accuracy down to ±0.02mm and surface finishes to 0.4um Ra are achieved through our precise tooling and processes.

- 36 Stamping Machines,10-200T

- Stamping Material: Aluminum Alloy, Stainless steel, Carbon Steel, Copper, Brass

- Working Time: 3 shifts 24 hours

In-house precision CNC machining

80% of the quality of the mold is due to the design, we strive to manufacture molds with the longest service life and fewer repairs.

- 27 CNC Machines(3-axis)

- 9 CNC Machines(4-axis)

- 3 CNC Machines(5-axis)

- 3 CNC turning-lathe Machines

- CNC Machining Material: Aluminum Alloy, Zinc Alloy,Magnesium Alloy, Stainless steel, Carbon Steel, Copper, Brass

- Working Time: 3 shifts 24 hours

surface treatment

Available Surface Finish:

- Polishing

- Sand blast

- Anodizing

- Electrophoresis

- Electroplating

- Passivation

- Powder Coating

- Painting

- Pad Painting

Workflows

The die casting industry has many tedious flows, and die casted products are more commonly used than other material products. We provide professional manufacturing services upon quotation, to save your time and cost, so we can achieve stable production and quality from design to T1 samples testing, with fast production and accurate control on lead time.Our professional experts team is always at your service, including innovation, design, prototyping, production, testing, checks and delivery.

Mold Design

2. Mold Flow analysis

3. DFM report

4. 3D Mold drawing

Mold Making

2. Heat Treatment Report

3. Weekly Progress Report

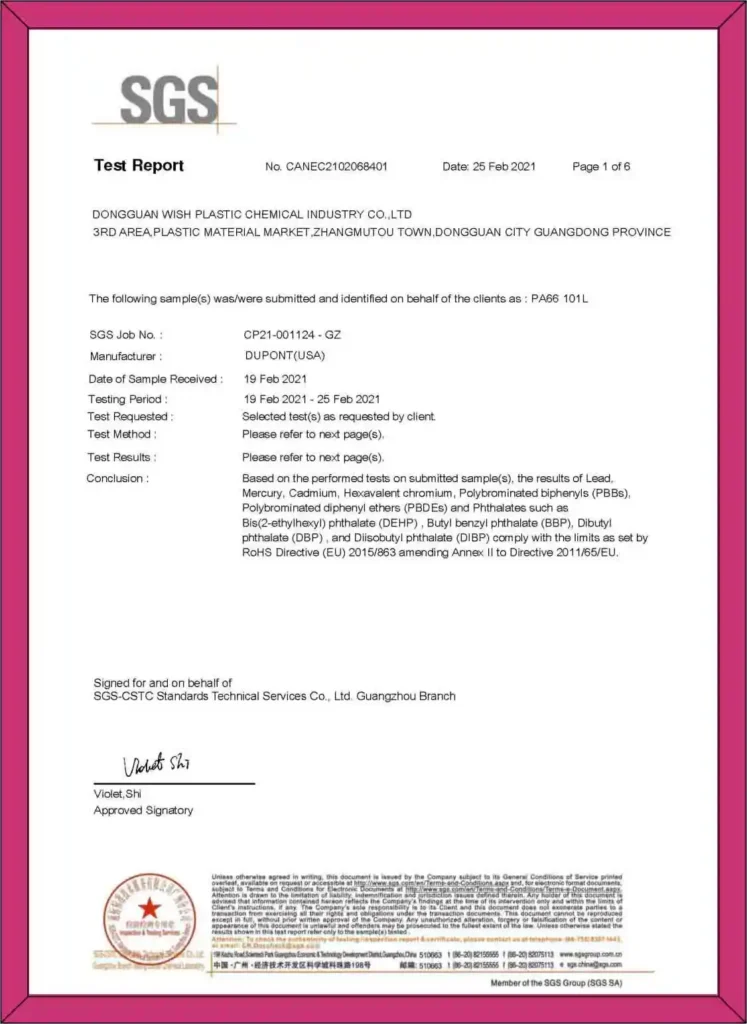

Making samples

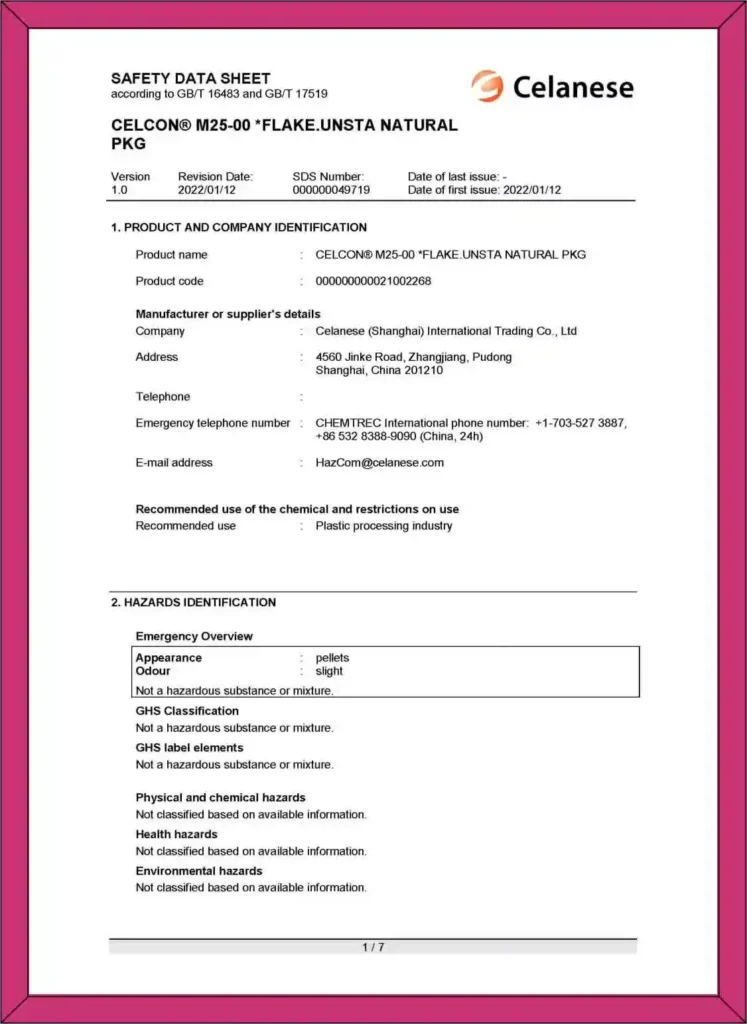

2. Material ROHS report

3. Limit samples&Report

MASS PRODUCTION

2. Process parameters

3. First sample test report

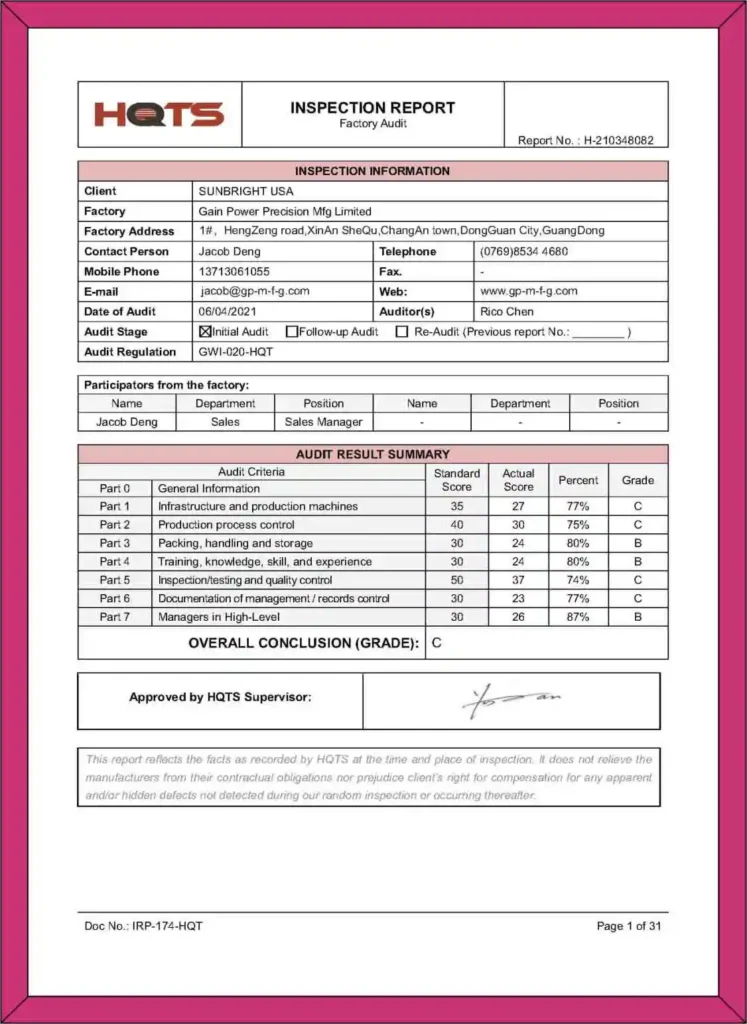

4. Inspection report

QUALLTY CONTROL

2. Material ROHS report

3. Salt spray test report

INSPECTION & PACKING

2. Limit samples

Materials

ALUMINUM ALLOY DIE CASTING

General material: ADC12,A380,A360,ADC10

Density: 2.7g/cm³

Suitable processes : Die Casting,Stamping,CNC Machining, Passivation, Electrophoresis,Painting

Zinc Alloy Die Casting

General material: Zamak3, Zamak5

Density:6.75g/cm³

Suitable processes : Die Casting,Stamping,CNC Machining, Passivation, Electroplating,Painting

MAGNESIUM ALLOY DIE CASTING

General material: AZ91D

Density: 1.8g/cm³

Suitable processes : Die Casting,Stamping,CNC Machining, Passivation, Painting

Metal Material List

| Material | Optional Machining Process | |||

| Material type | Material spec. | Die Casting | CNC Machining | Stamping |

| Aluminum | A2017,AL2024,AL6061,AL7075,2A12,AL5052,AL6082,AL6063,AL6060,AL7075-T73,MIC-6 | X | √ | √ |

| Stainless steel | 440C,410,420,465,17-4PH,303,304,316L,316F,303SE,15-5PH | X | √ | √ |

| Carbon Steel | 12L14,1025,1045,1018,CRS,C45,1013,S50,Mild steel,low carbon steel,Q235,Q345B,iron,grayiron,A36,1214,1215,1213 | X | √ | √ |

| Tool Steel | 4140,4130,NAK55,718H, PX9,A-265,4340,SKD11,SKD61,A2,M2,P20,S136,S7 | X | √ | X |

| Bronze | Phosphor bronze,Bearing Bronze,Oil Bronze,Alminum Bronze,Nickel aluminum bronzeTU1.TUP | X | √ | X |

| Copper | C11000.C12000,C12000,C26000,C51000,C36000,C18200,Tungsten copper,Berylliumcopper,WUCU | X | √ | √ |

| Brass | HPb63,HPb62,HPb61,HPb59,H59,H68,H80,H90,C360,C2600,C26000,C27000 | X | √ | √ |

Why Us

GPMFG

Integrated in-house die cast manufacturing center

Whatever you need, whether its simple hardware insertion or complicated mechanical assembling, GPMFG can offer time-saving and cost-saving services for your project (die casting blank products).

One-stop service

We provide one-stop service from prototyping, die-casting, CNC machining, surface treatment, stock procurement to assembly.

Flexible Production

Rapid prototype die castings can be made in quantities of 20 pieces or less, or you can move to large-scale die casting production with deliveries of 5,000 pieces or more at a time.

Excellent post-processing capability

We are able to provide various surface treatments: painting, powder coating, chromate conversion coating, anodizing, electroless nickel plating, screen printing, pad printing, laser engraving, etc.

Competitive Pricing

Based on GPMFG's full production equipment, complete die casting manufacturing capabilities, and different sized base setups, we can work with your mold inserts to achieve unit part and multiple part die casting production in less than 1 day.

Fast delivery

Prototype molds are completed within 1 week, production die casting molds are completed within 2-5 weeks, and die casting products are shipped within 1 week at the earliest.

Quality Assurance

Equipped with perfect testing equipment to ensure the reliable quality of die casting molds and die casting products, all items comply with ITAR and RoHS standards.

Our Factory

Professional Manufacturer

die casting workshop

Stamping Workshop

CNC Workshop

Laser engraved surface treatment

automatic detection

Full Inspection & Packaging

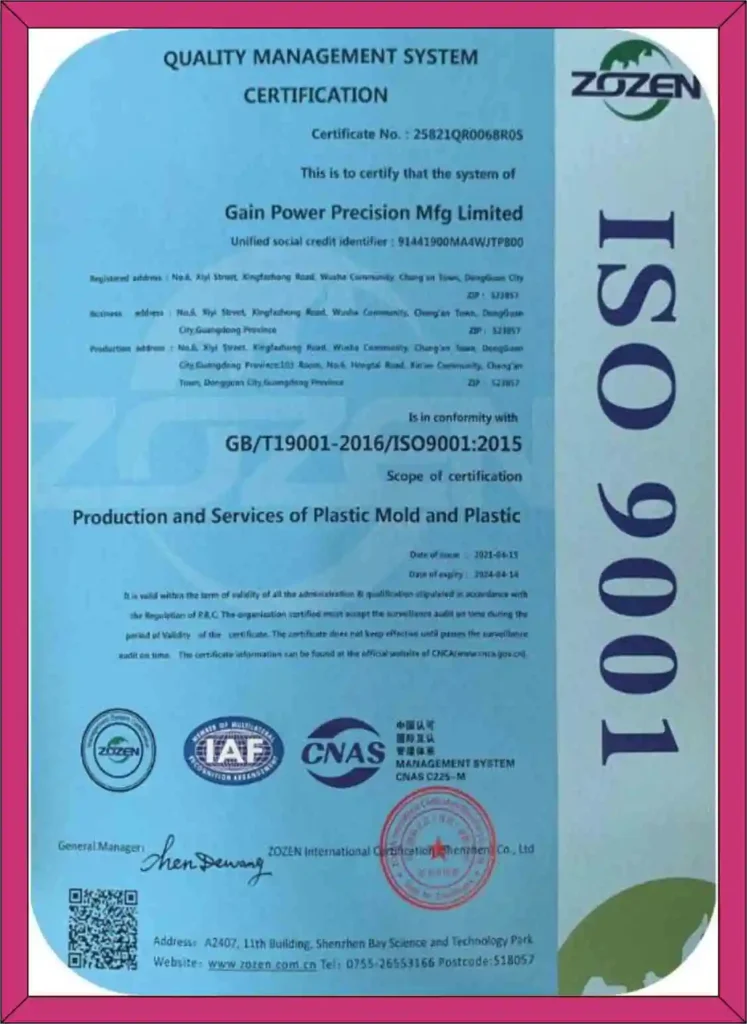

Quality

Quality

Inspection Equipments:

CMMs

Projectors

Mechanical inspection instruments

ROHS Detection instruments

Salt spray testers

Certification:

ISO9001:2005

IATF 16949:2016

They believe in GPMFG

Mauro Evatore

GPMFG handles all aspects from design to production seamlessly. Their expertise in precision mold manufacturing is clear from the flawless molded parts they deliver. I highly recommend them for any die casting needs. The quality is unbeatable and their customer service is truly exceptional.

Robert Hiley

The team was very responsive in the design phase, providing guidance to optimize the mold dimensions and material choices. The finished casting parts exceeded the tolerance specs with a smooth, flawless finish. I now have total confidence in GPMFG for handling the scaled production too!

Get Your Die Casting Project Started Today

GPMFG mold fabrication to die cast parts is done in-house. Our skilled engineering team understands your design goals and can offer a variety of recommendations so we can manufacture your parts quickly and economically. We know how to adjust molds or metal parts for perfect assembly, which will save you time and cost from scratch. Upload your files and get technical support!