GPMFG

Top mold tooling manufacturer in China

- Mold follow,Mold Design, Mold Manufacturing

- Prototype Molds,low life Molds up to 1 Million-shots Molds

- Single Cavity Molds, Multi Cavity Molds,Family Molds

- Plastic Injection Molds, Die Casting Molds

Professional mold makers with over 20 years of experience know you better and make you more profitable.

- Free Mold Flow Analysis

- Save 50-70% costs

- 40% reduction in delivery time

- Prototype manufacturing

- 100% tool ownership.

- Guaranteed after-sales service

- Timely feedback on project progress

- Project evaluation and professional advice

Our Services

Single Cavity Mold

Single cavity molds usually are applied for small or medium mass production.Each injection produces only one part,so the mold cost is low but the production cost is high. Lead-time: around 3-5 weeks.

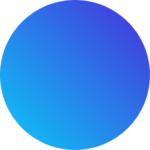

Multi Cavity Mold

Multi-cavity molds usually are applied for big mass production.Each injection produces several same parts,so the mold cost is high but the production cost is low. Lead-time: around 4-6 weeks.

Stack Mold

Our stack mold tooling is designed to increase your molding output and minimize part costs, with options for both equal and varying cavity numbers in each parting surface. Lead-time: around 4-6 weeks.

Family Mold

Family molds are a type of multi-cavity mold that allows for the production of different parts with varying shapes, sizes, and features in a single molding cycle. By using a family mold, we can increase production efficiency and reduce costs, as they can produce multiple parts simultaneously with one mold.

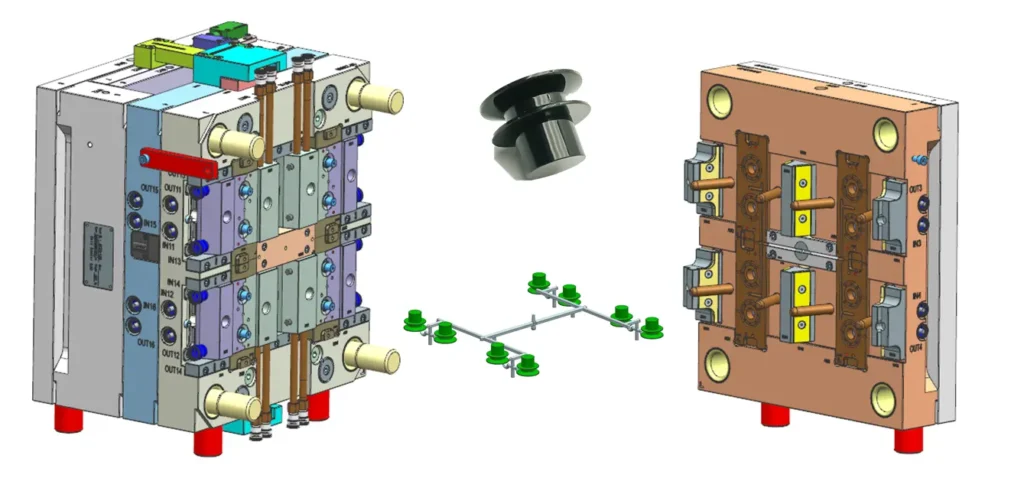

Perfume bottle cover Tooling/Mold

Industry: Cosmetic product packing

Mold Base steel:P20

Mold Cavity Steel :1.2083(HRC48-52)

Cavity: 8 Cavities

Mold Life:1,000,000 shot

Surface Finish:Mirror Polish

Mold Feature: Double ejection

Food Container Tooling/Mold

Industry: Foods packing

Mold Base steel:P20

Mold Cavity Steel :P20,BE-CU

Cavity: 1*1

Mold Life:1,000,000 shot

Surface Finish: Standard Polish

Mold Feature: Fast cooling for molding

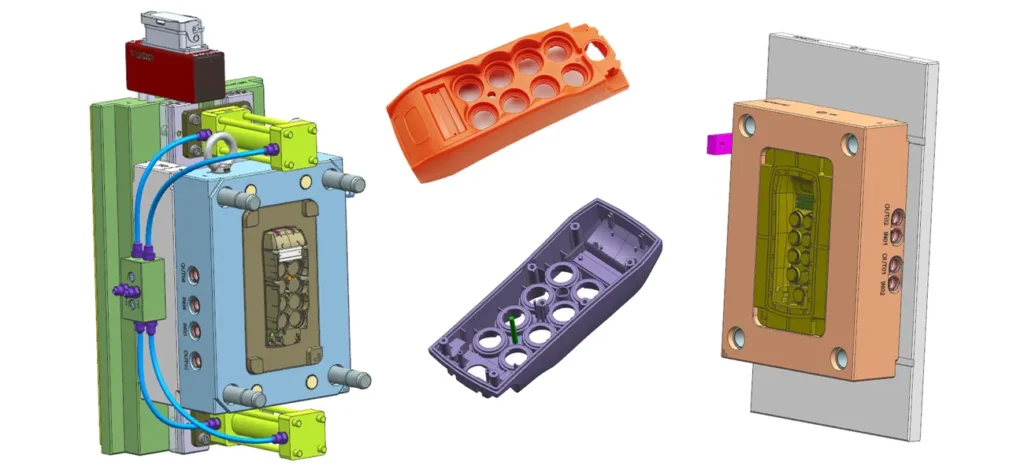

Controler Housing Tooling/Mold

Industry: Electronic & Electrical

Mold Base steel: 1050

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: YUDO hot nozzle

Electrical housing Tooling/Mold

Industry: Electronic & Electrical

Mold Base steel:S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: Colored Nylong

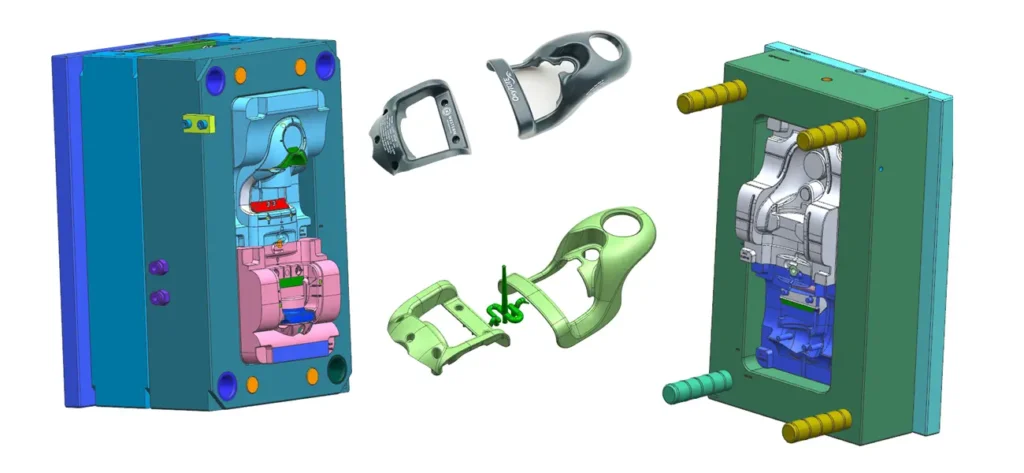

Medical Tooling/Mold

Industry: Medical device

Mold Base steel:S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1+1

Mold Life:500,000 shot

Surface Finish: VDI-27

Mold Feature: Family mold

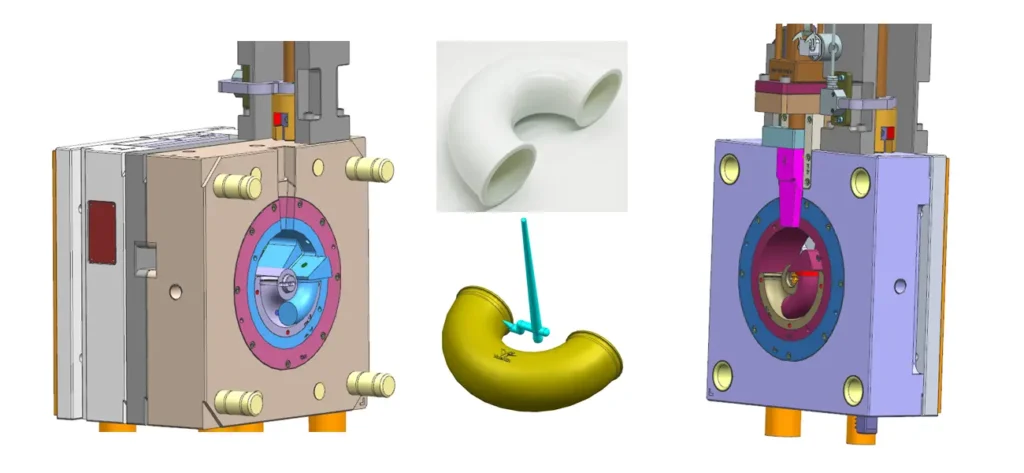

U pipe Tooling/Mold

Industry: Household

Mold Base steel:P20

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Arc slider

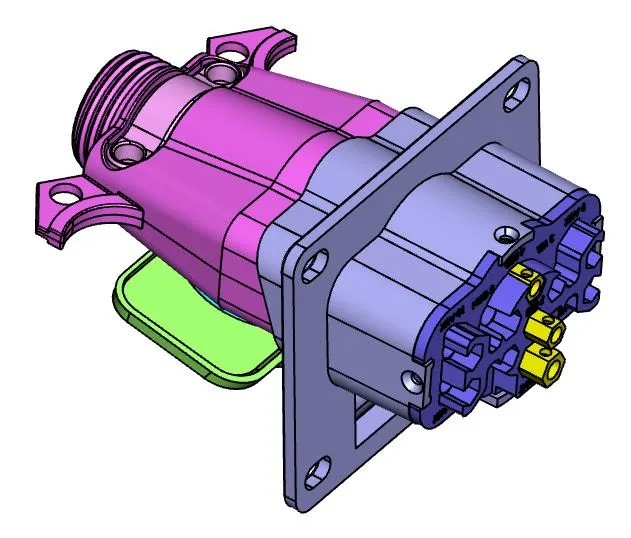

Oil pipe Tooling/Mold

Industry: Automobile

Mold Base steel: S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*2

Mold Life:500,000 shot

Surface Finish: MT-11010

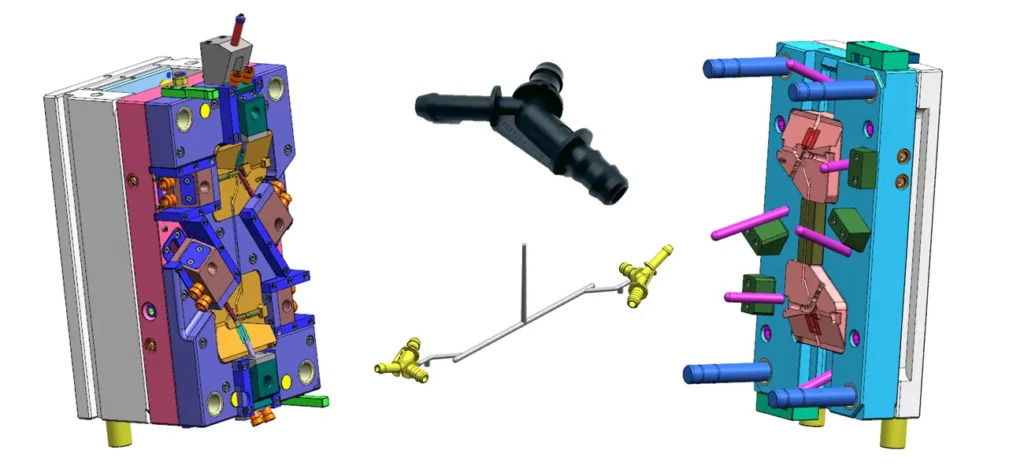

Mold Feature: Multiple Sliders

Automobile Tooling/Mold

Industry: Automobile

Mold Base steel:P20

Mold Cavity Steel :1.2343(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Synventive hot nozzle

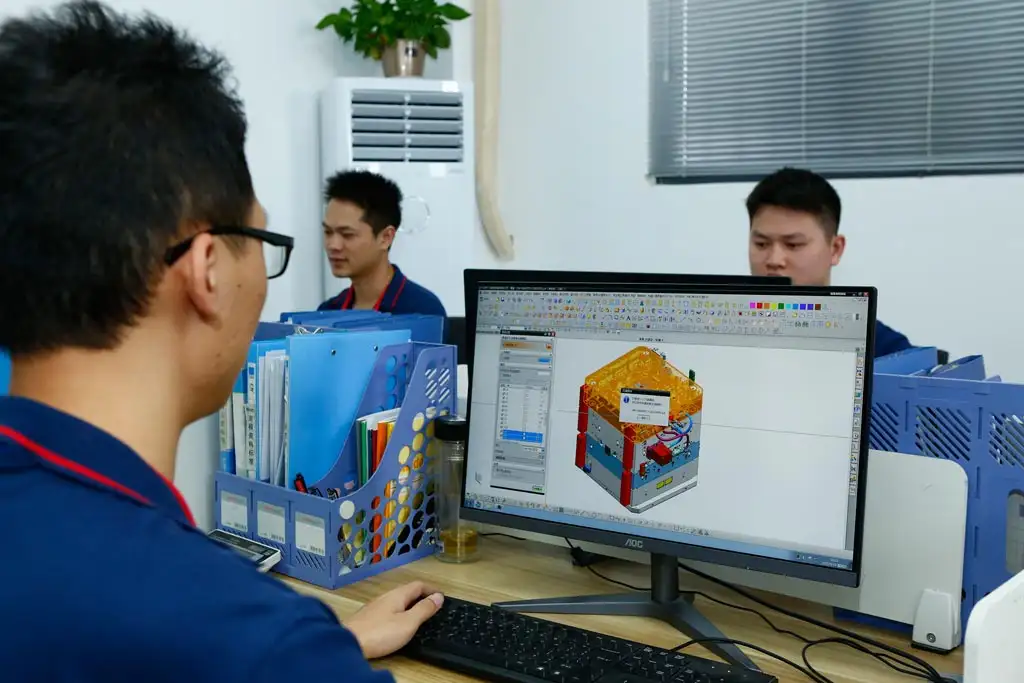

GPMFG provides complete Engineering support from Tooling/Mold Development,Manufactring,Test,Trial production and after sales

Products Analysis

Plastic Material Analysis & Draft Angle Analysis

Wall thickness Analysis & Part Feature optimization

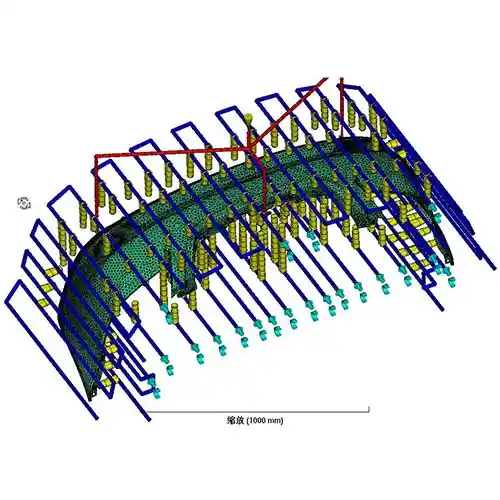

Mold Flow Analysis

Runner Layout & Filling Time/Pressure/

Temperature & Air traps

Sink Mark & Weld Mark & Warpage -XYZ Deflection

DFM

Parts basical information & Parts Optimization advice & Surface finish detail

Parting lines detail & Mold Layout&Idea detail

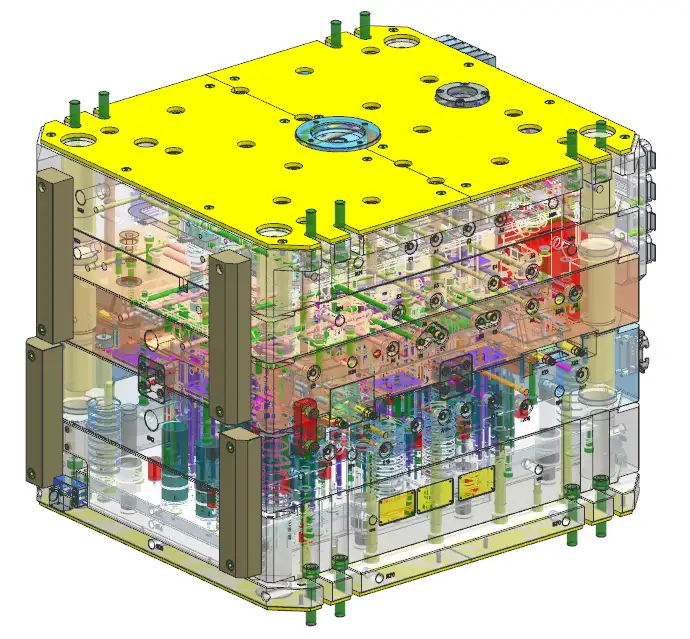

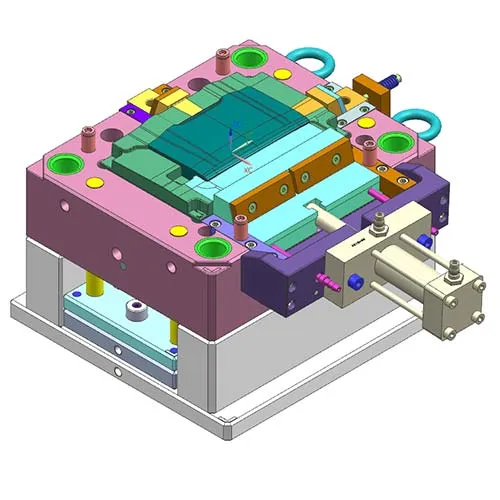

Molds 3D design

Mold drawing 2D & Mold drawing 3D & Mold BOM

Mold Components Drawing & Wire-cut&EDM drawing

Mold Design

- Products/Parts Analysis

- Products/Parts Optimization

- Mold Flow Analysis

- DFM(Design for Manufacturing)

- Tooling/Molds 3D design

- Weekly Progress Report

- Steel Certificate&Heat Treatment Report

- Full Tooling/Molds Test report

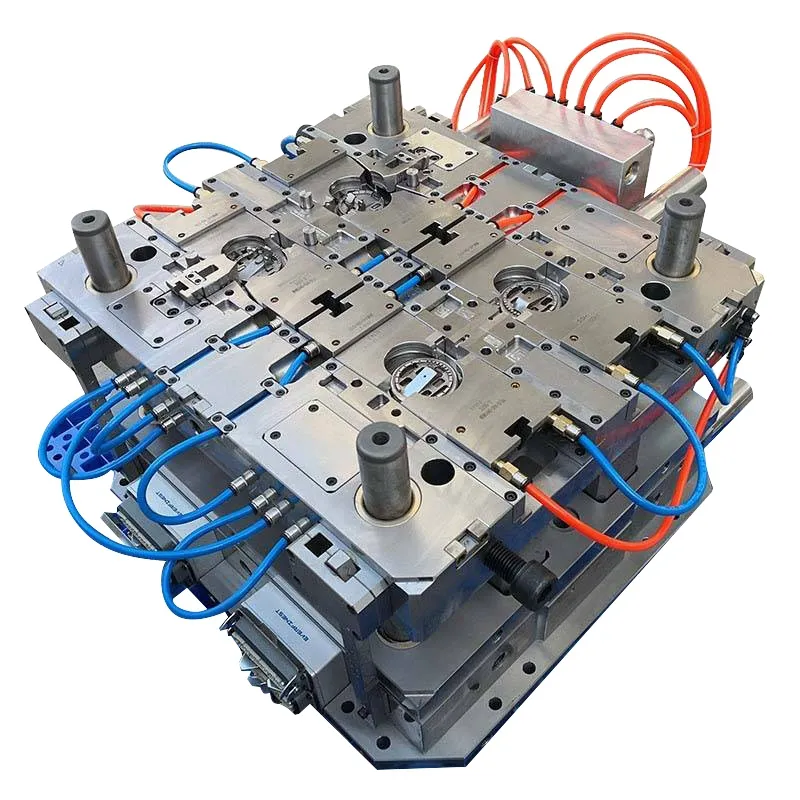

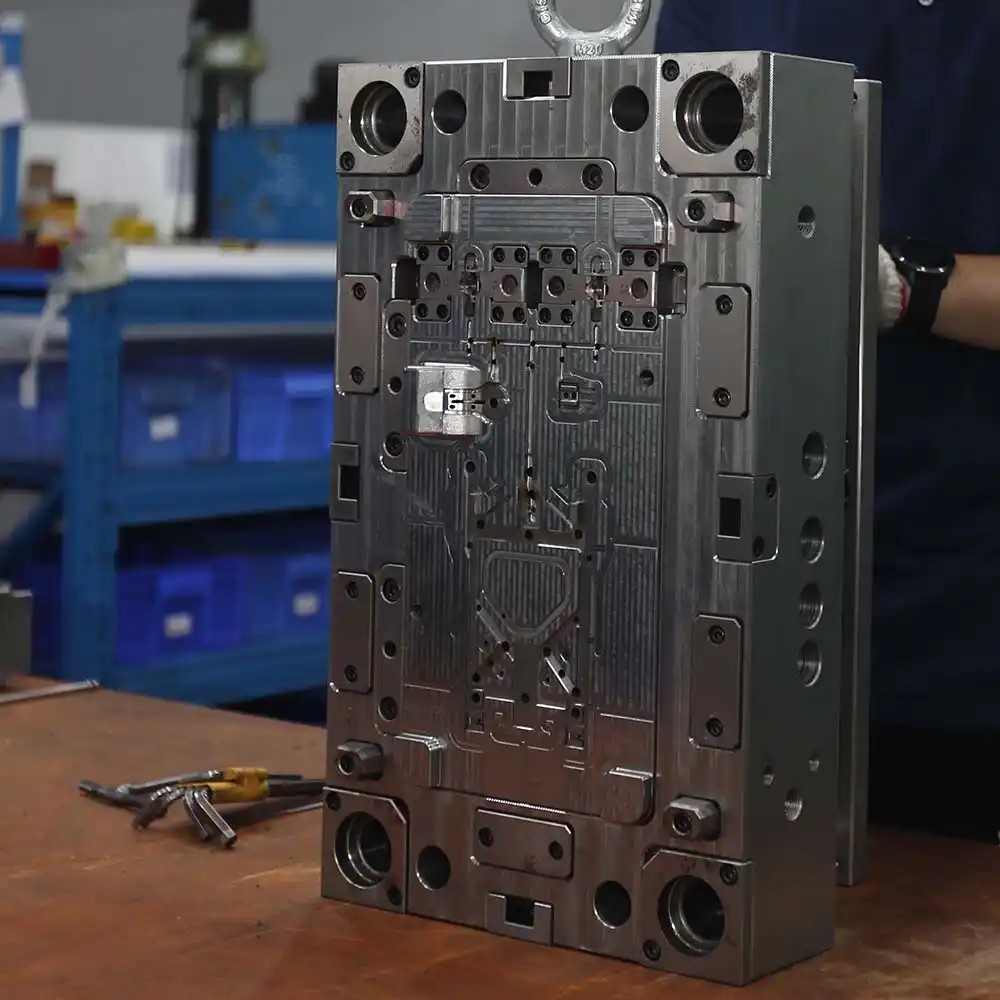

Mold Processing

MOLD MAKING IN-HOUSE

Our mold workshop is equipped with the latest machines, such as high-speed CNC machine tools, EDM wire cutting machines, and mirror processing sinker EDM machines, which help us to ensure that our molds are manufactured with the highest precision and high-quality surface finishes. Our shop has 30 skilled mold makers, most of whom have more than 10 years of experience in mold making, who are familiar with all the machining processes, cost every step of the way and can troubleshoot the mold making process.

CNC workshop

Our CNC workshop contains 10+ machining centers to accurately produce mold components within 0.05mm tolerance.

EDM workshop

10+ wire and sinker EDMs deliver precise cavities, pockets, and details down to 0.01mm tolerance.

Wire-cut workshop

High-speed wire EDMs with auto-thread capability provide efficient, accurate cutting of complex profiles.

Grinding workshop

Advanced grinding, lapping, and polishing machines create ultra-smooth mold core/cavity surfaces under 0.2μm Ra finish.

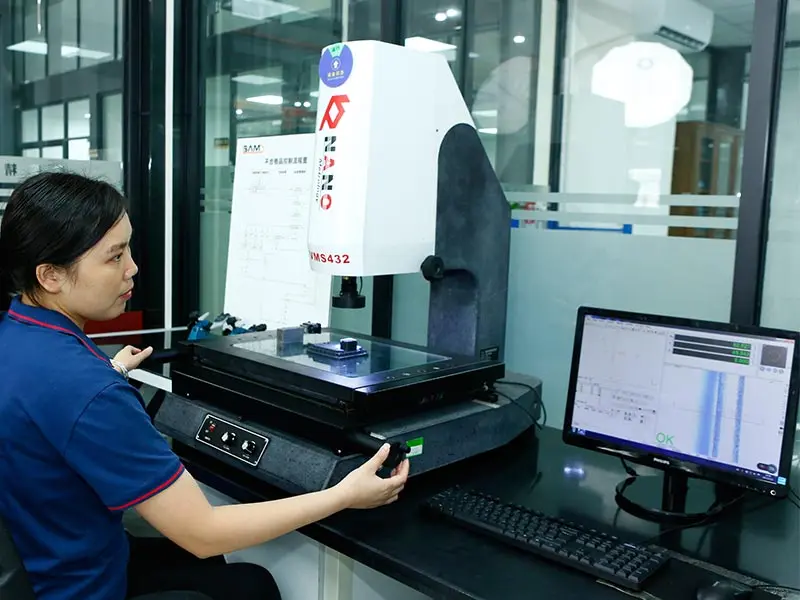

Quality Department

CMMs, projectors, vision systems, and lab testing rigorously inspect, validate, and verify mold tooling to certification standards.

Assembly Department

Assembly/testing validates aligned precision components for flawless mold performance and sampling.

Tooling Materials

We use high quality mold steels, selected based on hardness, polishability, corrosion resistance and manufacturability requirements. Our engineering experts specify the optimum grade for each mold component based on the material and process being produced.

- CARBON STEELS

- COLD WORK STEELS

- HOT WORK STEELS

- H.S. STEELS

- PLASTIC MOUID STEELS

Tooling Surface Finishes

The surface finishes to injection mold can be classified according to the SPI and VDI systems, which include gloss, semi-gloss, matte, and textured finishes. By selecting the appropriate surface finish to injection mold, GPMFG can help you achieve the desired appearance and functionality of the final product.

Mold surface treatment

- Glossy

- SPI-A1

- SPI-A2

- SPI-A3

- Matte

- SPI-C1

- SPI-C2

- SPI-C3

- Semi-Glossy

- SPI-B1

- SPI-B2

- SPI-B3

- Textured

- MT

- VDI

- YS

Final Mold Inspection and Parts Qualification

Mold inspection

- All of sliders or lifters can move properly

- Mold cavity and core move smoothly without interference

- No burrs or sharp corners on the mold base

- All of cooling outlets are equipped with proper adapters

- Mold core, cavity, and mold base are sprayed with rusty-protection oil

- Mold information brand is firmly fastened

parts inspection

- Part material is in accordance with customer’s definition

- Part color is correctly made according to pantone number

- All of part features are correctly and completely made

- No flash, deformation, shrinkage, crack, or other obvious appearance defects

- All of critical dimension and control number must be measured and qualified by SPC process.

- Part assembly test with other components from the whole system

- Drop test, vibration test, salt-spray, rubbing test

GPMFG is a professional plastic injection mold manufacturer with 20 years' experience.

Why Choose GPMFG

GainPower-MFG(GPMFG) is a top mold manufacturer in China that can produce a wide range of mold types. Within our production facility we have 27 mold making machines ranging in size from 50 tons to 1300 tons. These include CNC, EDM, wire cutting, lathe, CMM, milling, hot stamping, pad printing and screen printing units.

From insert molding and overmolding to spin-on molds, GPMFG can mass produce the molds you need for your project.

- Molds suitable for presses ranging from 50 to 1300T

- Up to 32-cavity molds

- Molds classified from Class 101 to Class 105

- In-house tool welding

- Tolerance: ±0.005mm

- Prototype molding, 2K/3-shot molding, insert & overmolding

Top Mold Companies You Can Trust

Working with GPMFG is not just a part, it's a guarantee of long-term profitability.

GPMFG is more than just a partner, it’s a promise of lasting success. Our collaborative approach to manufacturing ensures that your products are made with the highest quality standards and optimized for maximum profitability. With GPMFG, you can trust that your business will thrive for years to come.

Design & Solution

We design and build multi-component, stack molds, thin / thick wall molds, high cavitation high performance molds, high precision molds and metal insert molds. Our talented team will provide unique solutions for your projects.

- Innovative Tooling Concept

- Robust Design

- Optimized Cooling

- Fast Cycle

- Easy for Maintenance

Equipment & Accuracy

We are constantly refining our experience and equipment, updating not only technology but also expensive equipment, with tolerances of ±0.005mm.

- Double Sparking EDM Machine

- CNC Wire Cutting Machines

- laser Marker Machine

- Gun Drilling Machines

- Plastic Injection Machine

Quality & Reporting

GPMFG defines quality as total customer satisfaction. This drives us to settle for nothing less than for excellence in all aspects of our business. We supply the following documents to our customers.

- Mold Base Certificate

- Steel Certificate

- Heat Treatment Certificate

- Mold Trial Report

- Sample Inspection Report

Transportation & Safety

Our focus is on ensuring that your products are well-maintained. We take great care in handling the transportation and packaging of mold molding to ensure that your products are delivered in excellent condition.

- Anti-rust spray

- Vacuum package

- Strong Non-solid wood crate

GPMFG has worked with 1000+ companies around the world

Free Consultation & Free DFM.

Talk to us about your new project.

jacob@gainpower-mfg.com