jacob@gainpower-mfg.com

GPMFG

Top Mold / tooling manufacturer in China

- Mold follow,Mold Design, Mold Manufacturing

- Prototype Molds,low life Molds up to 1 Million-shots Molds

- Single Cavity Molds, Multi Cavity Molds,Family Molds

- Plastic Injection Molds, Die Casting Molds

Beginning of project

Mold Design&Project Management

GPMFG provides complete Engineering support from Tooling/Mold Development,Manufactring,Test,Trial production and after sales

- Products/Parts Analysis

- Products/Parts Optimization

- Mold Flow Analysis

- DFM(Design for Manufacturing)

- Tooling/Molds 3D design

- Weekly Progress Report

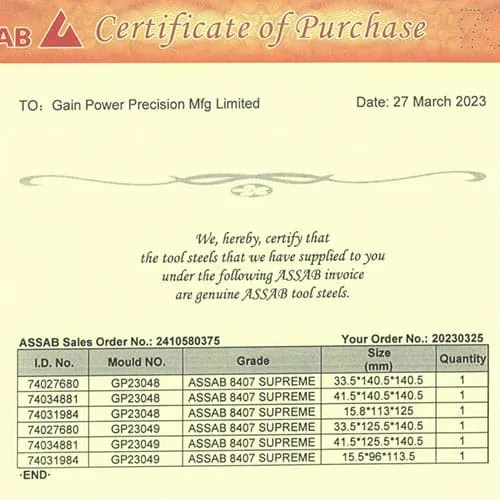

- Steel Certificate&Heat Treatment Report

- Full Tooling/Molds Test report

Engineer Software

- Auto CAD

- Unigraphics NX

- Pro-Engineer

- Autodesk Moldflow

- Solidworks

- PowerMilll

Usual drawing format:stp,step,x_t

Products Analysis& Optimization

- Plastic Material Analysis

- Draft Angle Analysis

- Wall thickness Analysis

- Part Feature optimization

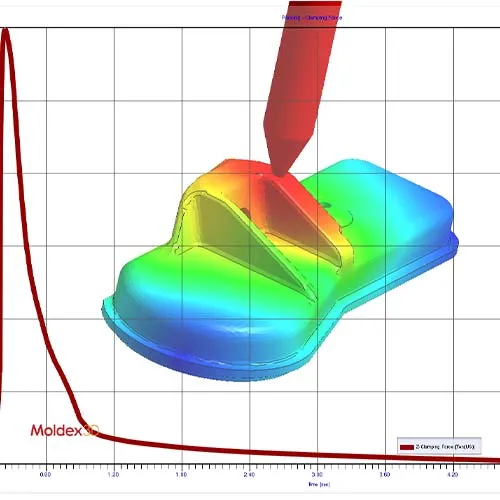

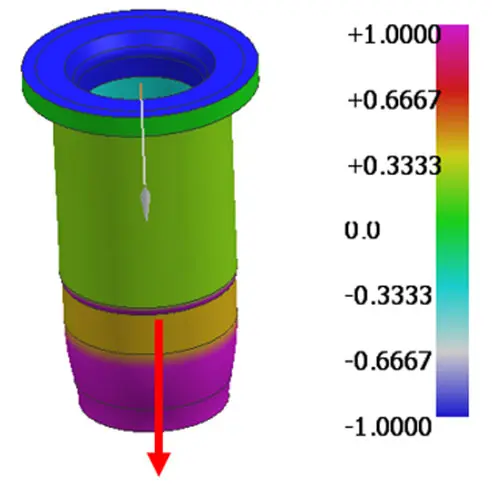

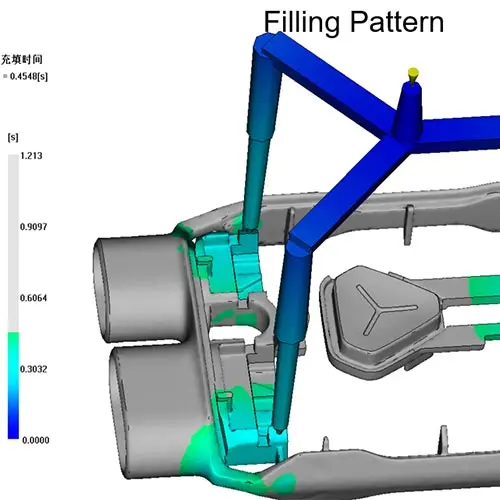

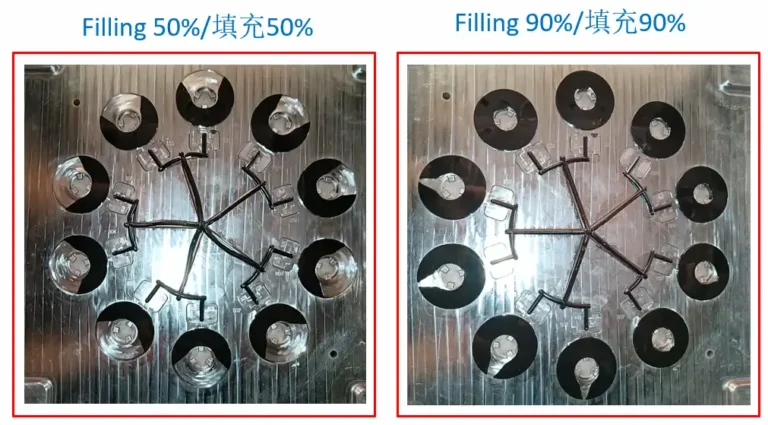

Mold Flow Analysis

- Runner Layout

- Filling Time/Pressure/Temperature

- Air traps

- Sink Mark

- Weld Mark

- Warpage -XYZ Deflection

DFM(Design for Manufacturing)

- Parts basical information

- Parts Optimization advice

- Surface finish detail

- Parting lines detail

- Mold Layout&Idea detail

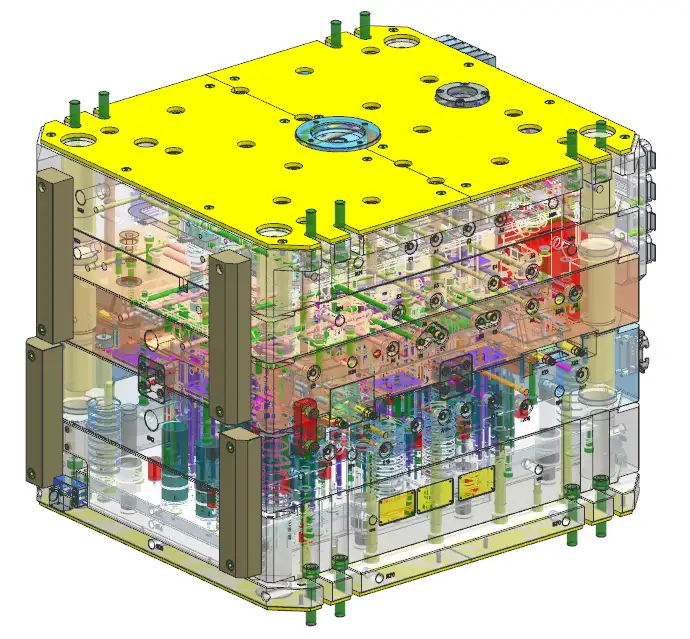

Tooling/Molds 3D design

- Mold drawing 2D

- Mold drawing 3D

- Mold BOM

- Mold Components Drawing

- Wire-cut&EDM drawing

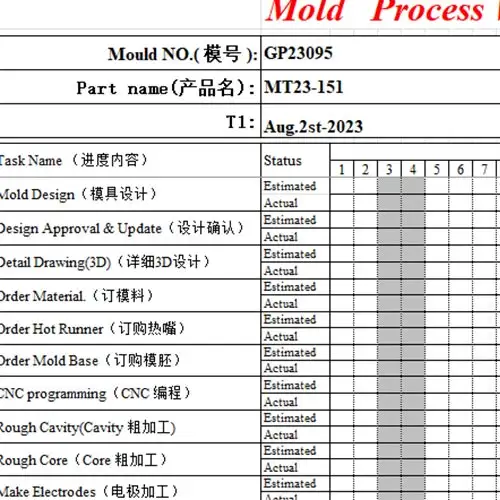

Weekly Progress Report

- Mold Design Progress

- Mold Steel Progress with pictures

- Mold components Progress with pictures

- Mold Machining Progress with pictures

- Mold Assembly Progress with pictures

Certificate

- Plastic Material ROHS report

- Steel Certificate

- Mold components Progress with pictures

- Heat Treatment Report

Full Tooling/Molds Test report

- Injection parameter report

- Mold Test video

- Product FAI report

- Injection Filling balance report

- Mold fitting report

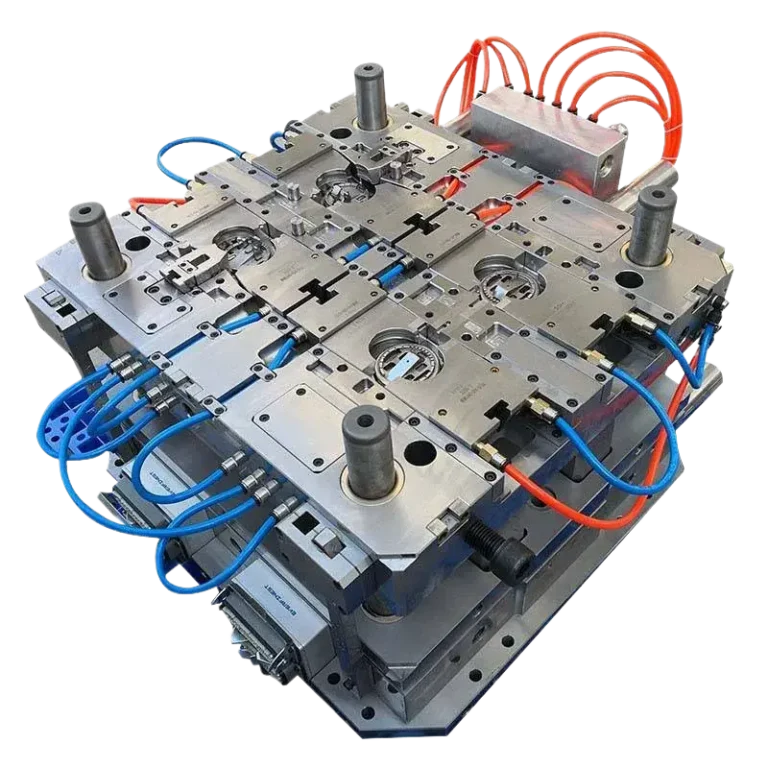

Customized Tooling/Molds For Your Industries

We Understand More About The Needs Of The Industry, You Just Need To Provide The Design.

Molds for Plastic Injection Molding

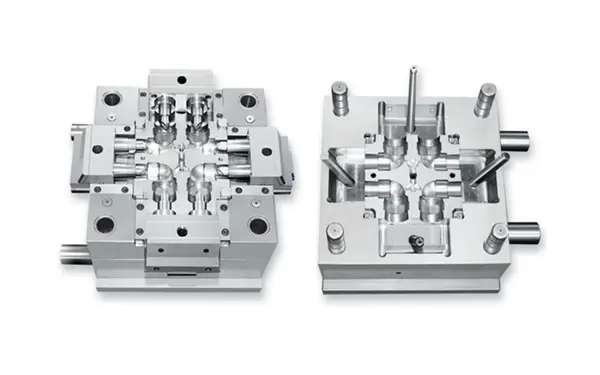

Single Cavity Mold

Single cavity molds usually are applied for small or medium mass production.Each injection produces only one part,so the mold cost is low but the production cost is high. Lead-time: around 3-5 weeks.

Multi Cavity Mold

Multi-cavity molds usually are applied for big mass production.Each injection produces several same parts,so the mold cost is high but the production cost is low. Lead-time: around 4-6 weeks.

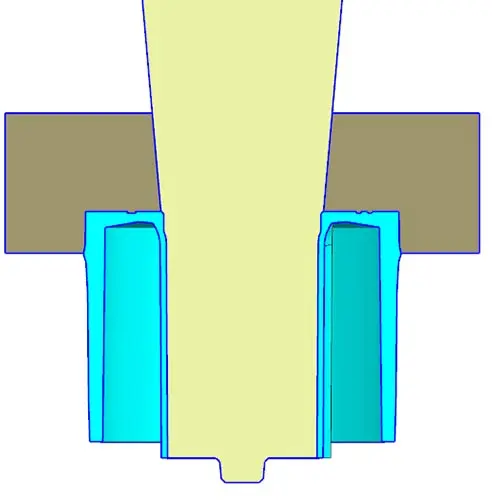

Stack Mold

Our stack mold tooling is designed to increase your molding output and minimize part costs, with options for both equal and varying cavity numbers in each parting surface. Lead-time: around 4-6 weeks.

Family Mold

Family molds are a type of multi-cavity mold that allows for the production of different parts with varying shapes, sizes, and features in a single molding cycle. By using a family mold, we can increase production efficiency and reduce costs, as they can produce multiple parts simultaneously with one mold.

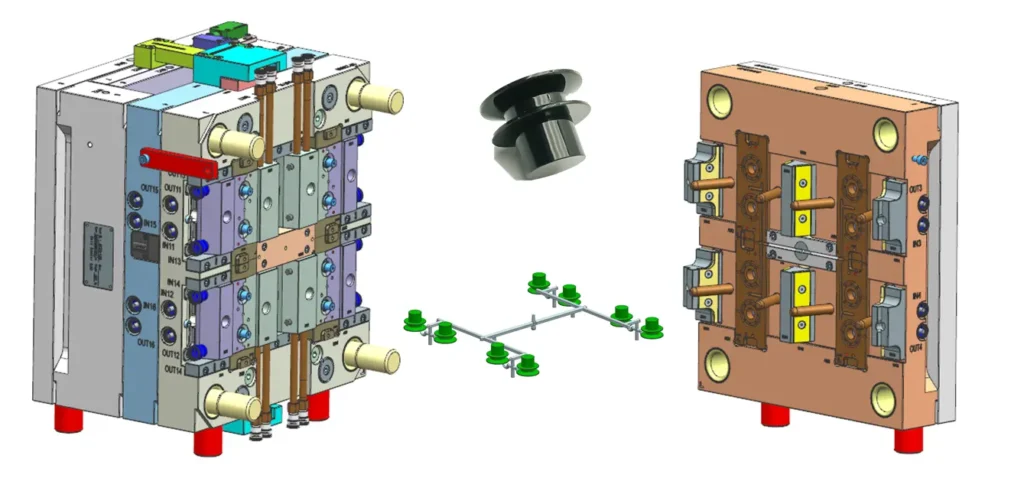

Perfume bottle cover Tooling/Mold

Industry: Cosmetic product packing

Mold Base steel:P20

Mold Cavity Steel :1.2083(HRC48-52)

Cavity: 8 Cavities

Mold Life:1,000,000 shot

Surface Finish:Mirror Polish

Mold Feature: Double ejection

Food Container Tooling/Mold

Industry: Foods packing

Mold Base steel:P20

Mold Cavity Steel :P20,BE-CU

Cavity: 1*1

Mold Life:1,000,000 shot

Surface Finish: Standard Polish

Mold Feature: Fast cooling for molding

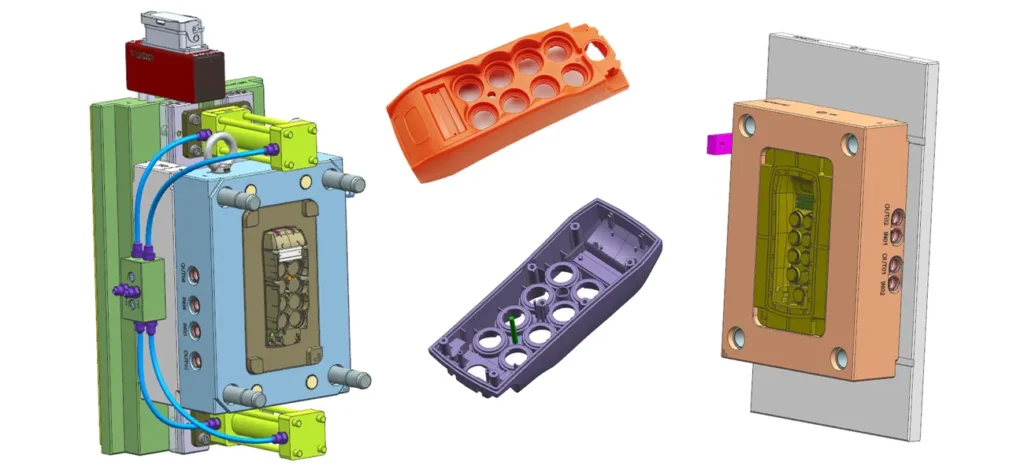

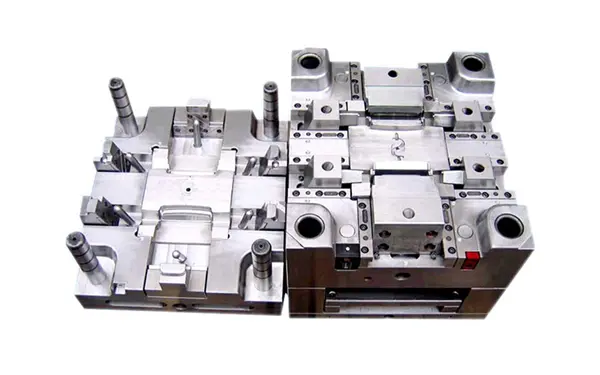

Controler Housing Tooling/Mold

Industry: Electronic & Electrical

Mold Base steel: 1050

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: YUDO hot nozzle

Electrical housing Tooling/Mold

Industry: Electronic & Electrical

Mold Base steel:S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: Colored Nylong

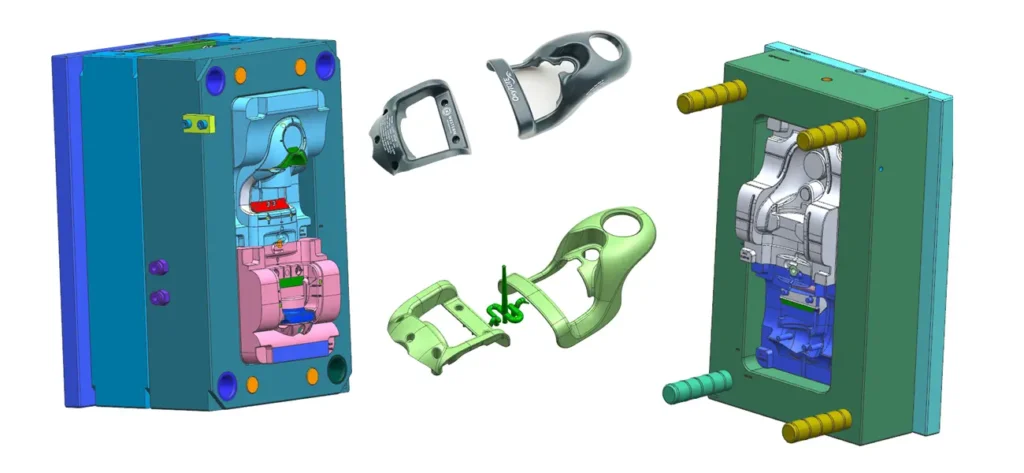

Medical Tooling/Mold

Industry: Medical device

Mold Base steel:S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1+1

Mold Life:500,000 shot

Surface Finish: VDI-27

Mold Feature: Family mold

Medical Tooling/Mold

Industry: Medical device

Mold Base steel:P20

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*4

Mold Life:1,000,000 shot

Surface Finish: Mirror Polish

Mold Feature: HASCO hot nozzle

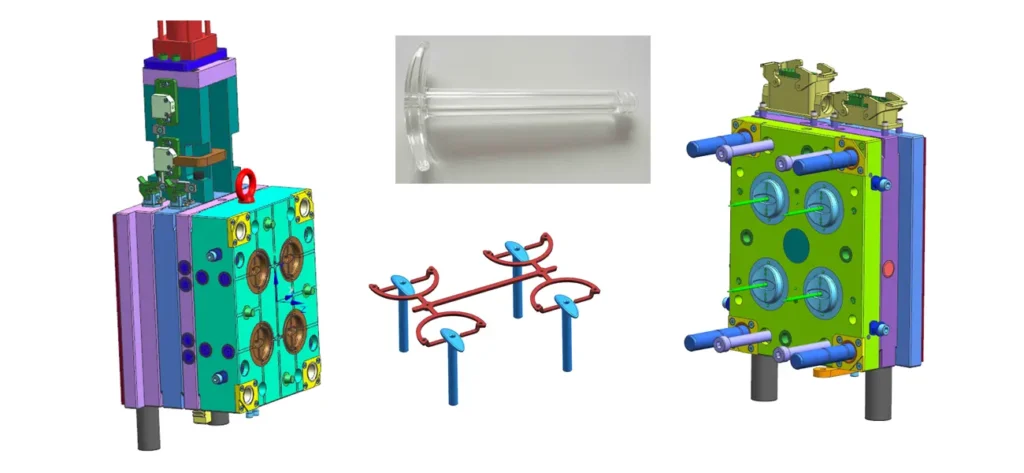

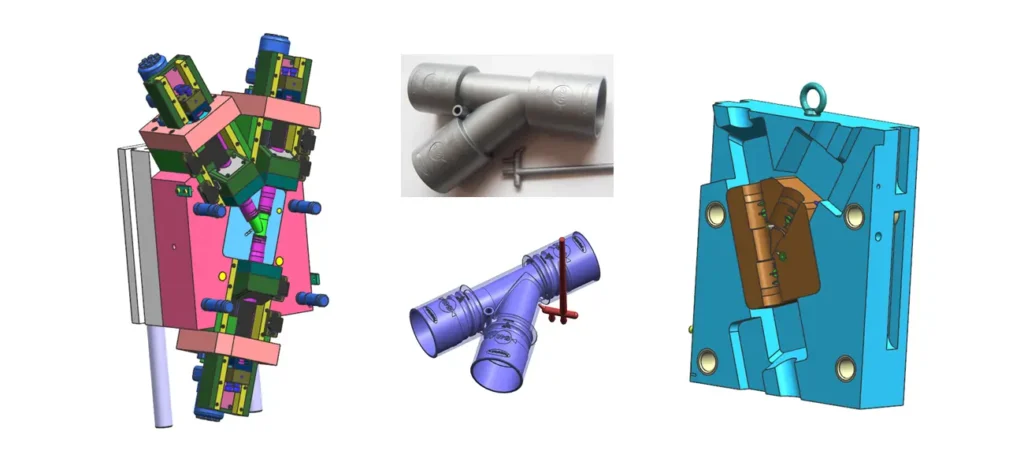

T-branch pipe Tooling/Mold

Industry: Household

Mold Base steel:P20

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Unscrewing movement

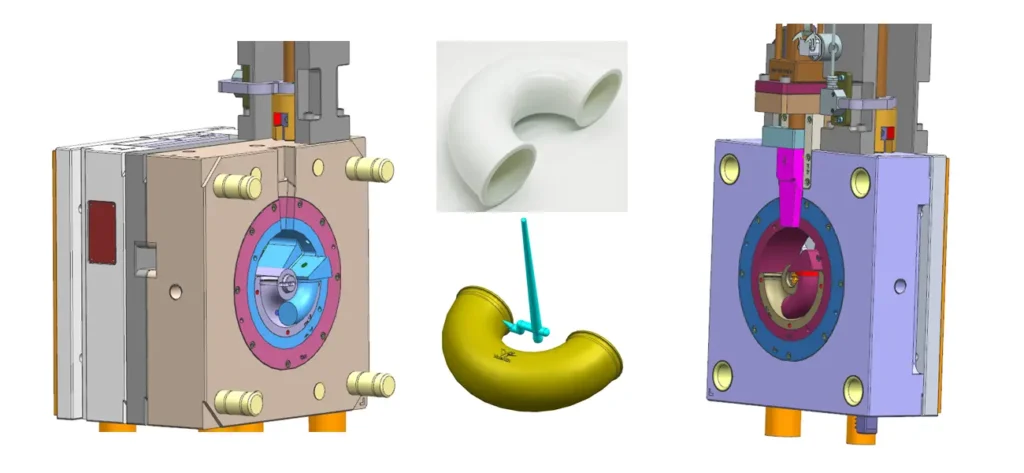

U pipe Tooling/Mold

Industry: Household

Mold Base steel:P20

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Arc slider

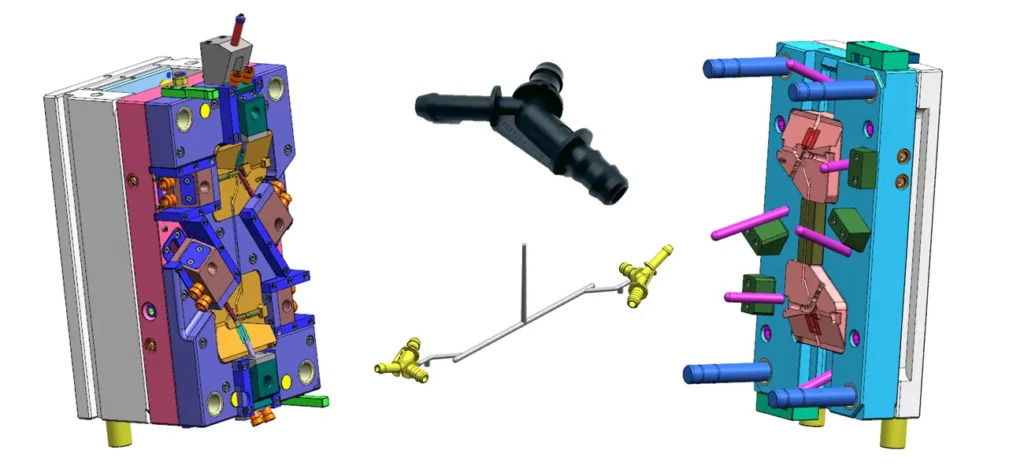

Oil pipe Tooling/Mold

Industry: Automobile

Mold Base steel: S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*2

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: Multiple Sliders

Automobile Tooling/Mold

Industry: Automobile

Mold Base steel:P20

Mold Cavity Steel :1.2343(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Synventive hot nozzle

Gallery of Molds

Finished Products Center

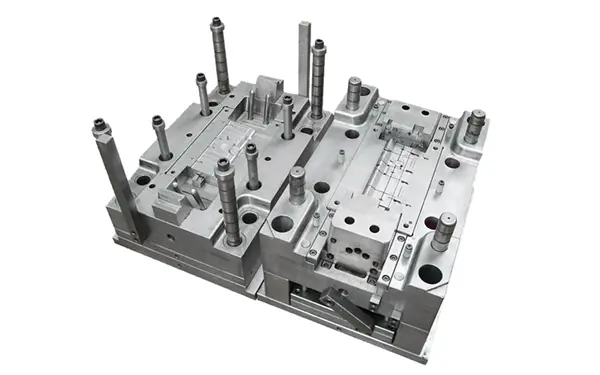

Mold Manufacturing

DFM and mold design

Injection mold design begins with a DFM program (Design for Manufacturability), presenting crucial mold design information such as dimensions, cavity layout, runner system, pouring method, parting line, ejection method, mechanical design, accessories, steel selection, and cooling design. After customer approval, detailed 3D design and NC programming are carried out, taking 3-5 days for a complete design. Complex projects may require mold flow analysis or frequent part design updates, prolonging the process.

Planning, Mold base, steel and accessories preparation

Upon mold design approval, our project manager will create a detailed project schedule covering the entire process until T1 sampling. Your assigned project manager at GPMFG will provide weekly updates. Mold base and steel can be ordered immediately after design approval, while accessories like the hot runner system may have longer lead times. It is crucial to closely monitor and track these procedures to avoid delays in subsequent steps.

Rough machine

In order to obtain the desired rough shape or cavity/core, the steel must undergo initial sizing, milling, drilling, and lathe processes. Typically, a steel thickness of 0.15-0.3 mm is retained for precision machining in subsequent stages.

Heat treatment

Heat treatment is a critical process following rough machining, as it serves two key purposes: achieving specific hardness levels and attaining internal balance. For instance, materials like 1.2343 and 1.2344 typically require hardening to a range of HRC48-52.

CNC precision machining

CNC precision machining involves meticulous attention to detail. Unlike rough machining, the CNC process operates at a slower pace with reduced cutting amounts. This method produces finely machined mold inserts with a smooth, glossy finish and accurate dimensions, achieving a maximum tolerance of 0.01-0.005mm.

Wire cut and EDM

Wire cutting is specifically used for various through holes (ejector pin holes, lifters, inserts), while EDM is suitable for features that cannot be machined by CNC due to depth or narrowness. To minimize the time and cost associated with EDM, experienced designers optimize mold design by dividing the main insert into multiple sub-inserts. This allows for direct CNC machining of the inserts, reducing the reliance on wire cutting and EDM processes.

Surface Finish and Fitting

Once all the components have been completed and prepared, our engineers gather them together and expertly assemble them according to the design drawing. This crucial task heavily relies on their vast experience and exceptional skills. In some instances, certain parts may require polishing or even reworking in order to achieve a perfect fit. Moreover, the core or cavity often have specific surface finish requirements, such as texture, polish, or engraving, which are meticulously addressed.

Mold trial

When everything is prepared, we will put the mold on the injection molding machine for a test. Make sure you clearly state your requirements, how many plastic parts you need as samples, instruct the moldmaker to use the correct resin, and that injection parameters and measurement reports should be provided with the molded plastic parts.

Mold and part inspection

Mold inspection

- All of sliders or lifters can move properly

- Mold cavity and core move smoothly without interference

- No burrs or sharp corners on the mold base

- All of cooling outlets are equipped with proper adapters

- Mold core, cavity, and mold base are sprayed with rusty-protection oil

- Mold information brand is firmly fastened

parts inspection

- Part material is in accordance with customer’s definition

- Part color is correctly made according to pantone number

- All of part features are correctly and completely made

- No flash, deformation, shrinkage, crack, or other obvious appearance defects

- All of critical dimension and control number must be measured and qualified by SPC process.

- Part assembly test with other components from the whole system

- Drop test, vibration test, salt-spray, rubbing test

About GPMFG

GainPower-MFG is a top mold manufacturer in China that can produce a wide range of mold types. Within our production facility we have 27 mold making machines ranging in size from 50 tons to 1300 tons. These include CNC, EDM, wire cutting, lathe, CMM, milling, hot stamping, pad printing and screen printing units.

From insert molding and overmolding to spin-on molds, GPMFG can mass produce the molds you need for your project.

- Molds suitable for presses ranging from 50 to 1300T

- Up to 32-cavity molds

- Molds classified from Class 101 to Class 105

- Prototype molding, 2K molding, 3 shot molding, insert & overmolding

- In-house tool welding

- Tolerance: ±0.005mm

Selection of Mold Steel

| Component Name | Steel&Hardness | Equivalent Steel | Mold Life(Shot) | Price Index | Applications |

| Mold base | 1050 | 1730 | 500,000 | 1 | Plastic injection mold |

| LKM P20 | 2311 | 1,000,000 | 1.35 | Plastic injection mold | |

| LKM P20 | 2311 | 500,000 | 1.35 | Die-casting mold | |

| H13 (HRC 44-46) | 2344(HRC44-46)/SKD61 | 1,000,000 | 2.1 | Plastic injection mold | |

| Mold Cavity/Core | P20 | 2311/718H/2378 | 200,000 | 1 | Plastic injection mold |

| P20H(HB330-370) | 2738H/718HH/NAK80 | 300,000 | 1.3 | Plastic injection mold | |

| S136H(HB290-330) | 2083H/420H/2316H | 500,000 | 2.2 | Plastic injection mold | |

| S-136 (HRC 48-52) | 2083/420ESR/2316 | 1,000,000 | 3.2 | Plastic injection mold | |

| H13 (HRC 48-52) | 2344/2343/SKD61 | 1,000,000 | 3.2 | Plastic injection mold | |

| H13 (HRC 48-52) | 2344/2343/SKD61 | 80-150K | 3.2 | Die-casting mold | |

| 8407 (HRC 50-52) | 8418 | 150-300K | 5 | Die-casting mold |

Mold Class & Life

Mold Class | Purpose | Shot Life | Tolerance | Cost | Lead Time |

Class 105 | Prototype Testing | Under 500 cycles | ± 0.02mm | $ | 7-10 days |

Class 104 | Low-volume Production | Under 100.000 cycles | ± 0.02mm | $$$ | 10-15 days |

Class 103 | Low-volume Production | Under 500.000 cycles | ± 0.02mm | $$$$ | 10-15 days |

Class 102 | Medium-volume Production | Medium to high production | ± 0.02mm | $$$$$ | 10-15 days |

Class 101 | High-volume Production | Over 1,000,000 cycles | ± 0.02mm | $$$$$$ | 10-18 days |

Facilitate On-Demand Manufacturing for Quicker and Simpler Results.

Once you are prepared to commence your upcoming venture, you can effortlessly upload your 2D/3D CAD design files and our team of engineers will promptly provide you with a quotation within 24 hours.

- Free Mold Flow Analysis

- Save 50-70% costs

- 40% reduction in delivery time

- Prototype manufacturing

- 100% tool ownership.

- Guaranteed after-sales service

- Timely feedback on project progress

- Project evaluation and professional advice

Jacob Deng

- jacob@gainpower-mfg.com

- +86 132 1516 3182