jacob@gainpower-mfg.com

OEM Solution -

Your Partner for Contract Manufacturer

One-stop OEM manufacturer for design, prototyping, manufacturing, assembly and shipping

- 30% less than local prices

- 100+ OEM product experience

- 40% reduction in delivery time

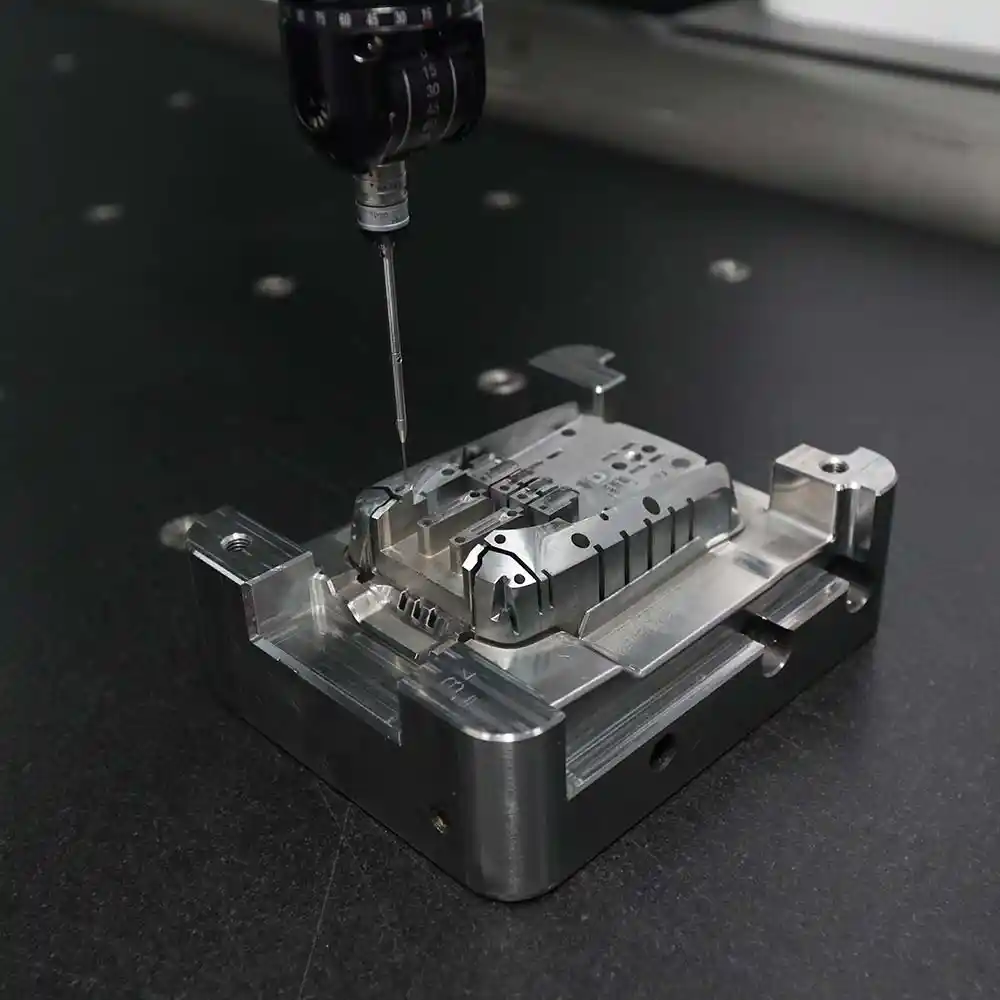

Complete manufacturing facilities

Includes CNC, EDM, wire EDM, milling, drilling, all under one roof

Export Manufacturing Experience

50% of our injection molded products are mainly exported to USA, Brazil, Italy, Germany, France, Japan and UK

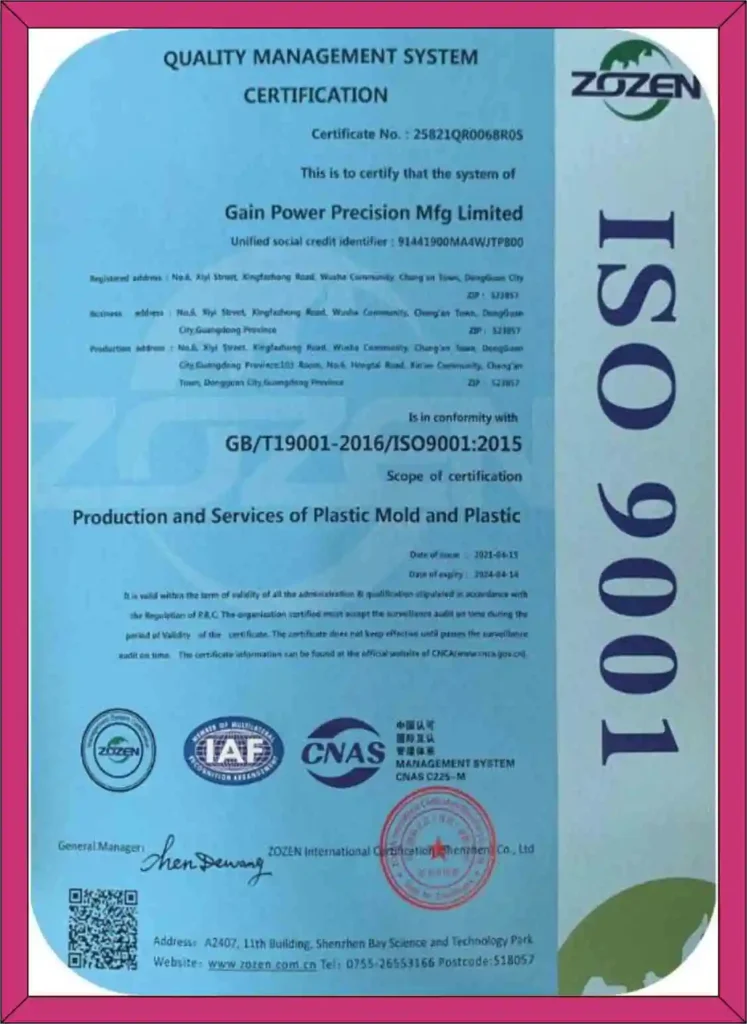

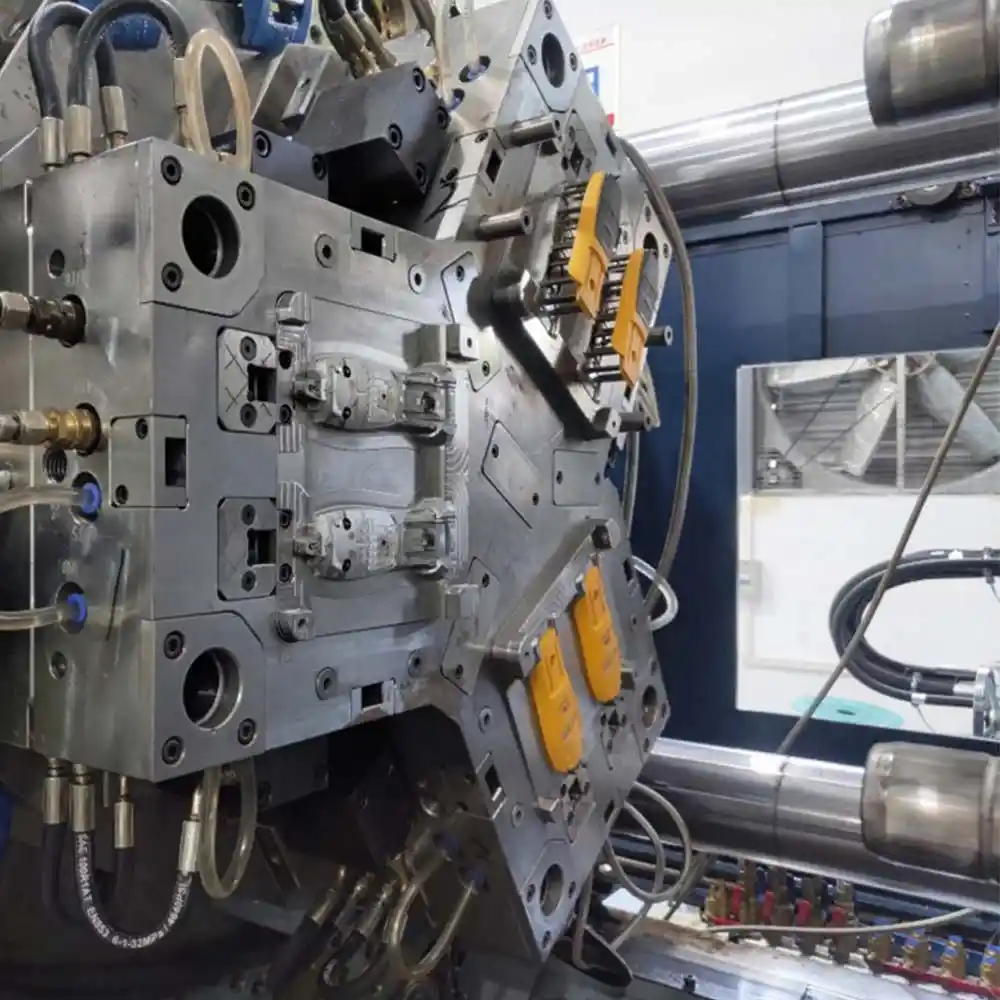

State-of-the-art facilities

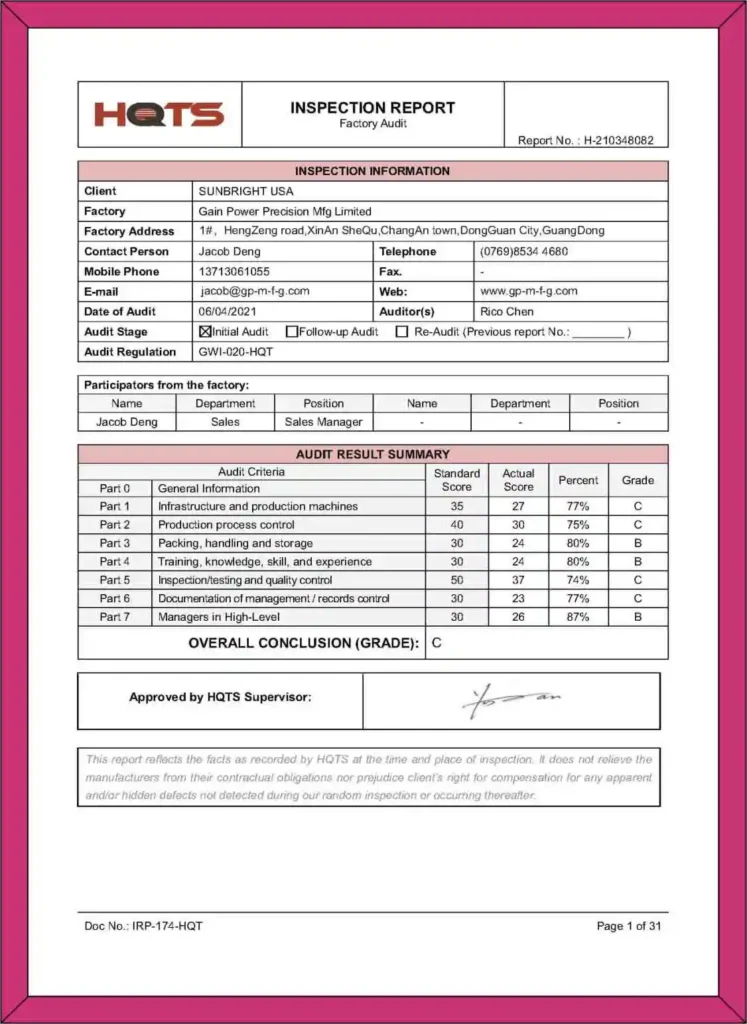

ISO 9001 certified and equipped with machines ranging from 50 tons to 800 tons, which allows us to meet orders for plastic parts of all shapes and sizes

XIAOMI

SIEMENS

VIVO

MIDEA

ANKER

RYOBI

JADA TOY

INDAUX

AKRON

SUNBRIGHT

VALENTIN

plasticos

TRUSTED BY INDUSTRY GIANTS

OUR PARTNERS

As a contract manufacturer our expertise includes engineering, product design, injection molding, custom molding, sub- and finished assembly and the on-time delivery of components and finished products for major industry. We streamline the total manufacturing process from start to finish, from supply-line development and management, process qualification, product testing and final assembly, all the way to drop shipping.

What we have produced

what makes us different

Our services - Not just a quotation

Reducing business risk through long-term partnerships involves more than just chasing the lowest price. True value comes from aligning with suppliers committed to providing robust quality, transparency, performance guarantees, and collaborative solutions that support the long-term success of your business.

Zero Defects and No Production Interruptions

With ISO-certified quality management systems, real-time process monitoring, and rigorous quality control testing, we ensure zero defects and prevent production interruptions.

Competitive Transparent Pricing

With cost analysis, we meet project budgets within 2% variability while maintaining transparent supplier pricing.

On-Time Delivery Avoiding Added Freight Costs

Our lean manufacturing workflows result in 95% on-time delivery over the past year, avoiding extra freight costs.

Capacity Scaling Through Investments

Over the last 5 years, we have increased manufacturing capacity by 40% and facility space by 30% to accommodate business growth.

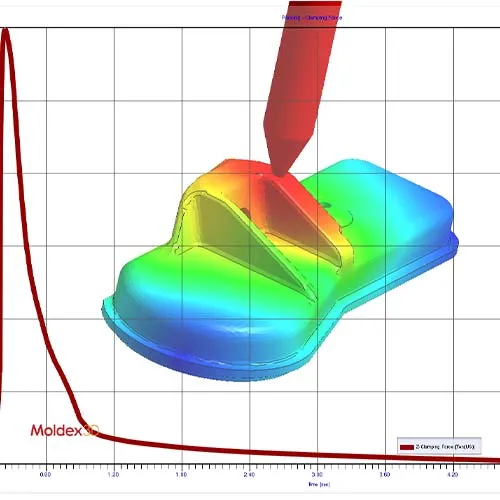

Design for Manufacturability Optimization

Our certified manufacturing engineers provide detailed DFM analysis to reduce part costs by an average of 15-20%.

Production Infrastructure for High-Mix Demands

Our global facilities and cellular manufacturing model supports high-mix, low- to high-volume production of parts from 10 grams to 50 kilos in size.

Flexibility for Fluctuating Seasonal Volumes

With redundant capacity and flexible scheduling, we meet fluctuating seasonal demands within a +15% volume flexibility range.

Collaborative Capital Planning and Alignment

For any capital investments exceeding $500K, we present detailed business case proposals to customers for feedback.

Industries We Serve

Automobile

- Large interior and exterior trim components

- Under-hood applications

- Automotive component prototyping

Consumer and Houseware

- Convenience Goods

- Cosmetics

- Household Goods

Rubber

- O-rings

- Bushings

- Stoppers

Household

- Drinkware

- plastic kitchenware

- BBQ accessories

Electronics

- Consumer electronics

- Electronic enclosures and housings

- Telecommunications equipment

Medical

- Medical instrumentation

- Diagnostic equipment

- Pharmaceutical packaging

Construction

- Windows

- Insulation

- Piping

Hardware

- Tool boxes

- Tool housings

- Lawn and garden parts

Packaging

- Foldable Small Containers

- Pallets

- Containers

How we work for you

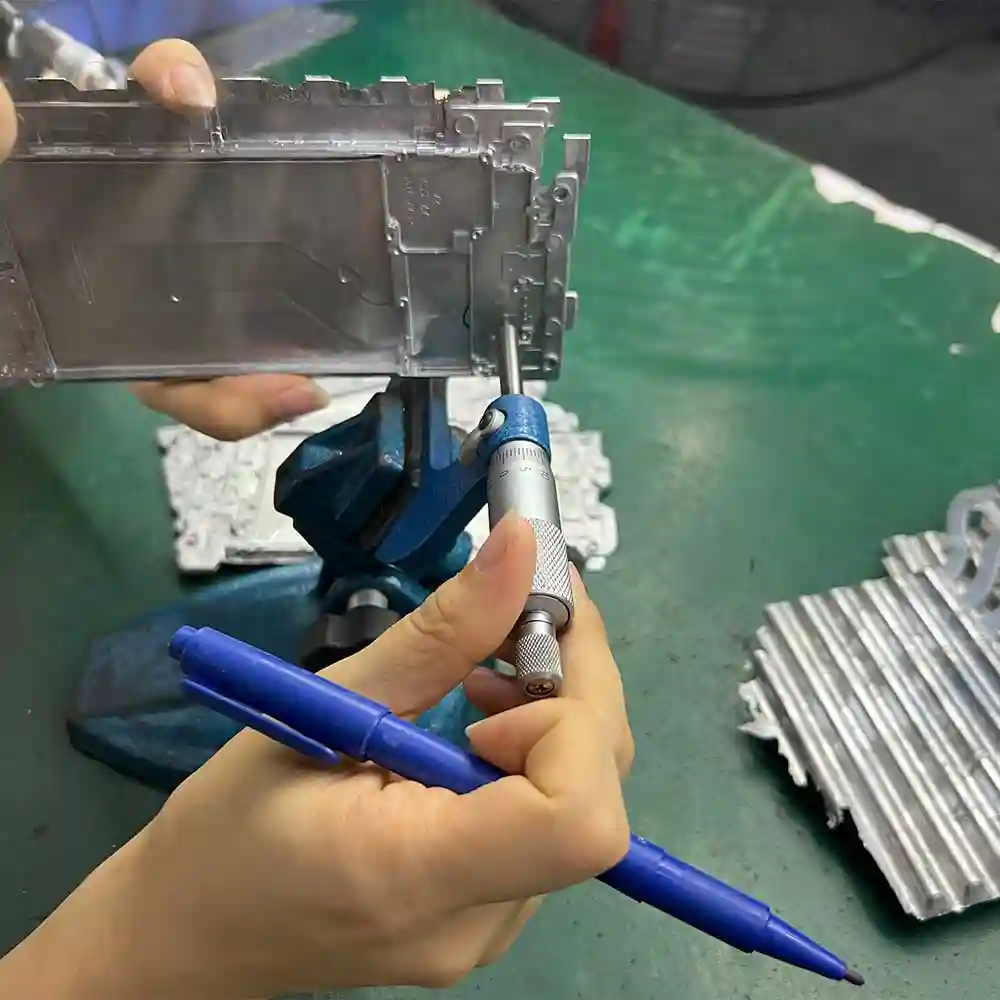

Quality and Consistency:

We prioritize meeting our customers’ stringent quality standards and ensure consistency in size, finish and overall performance from batch to batch.

- Document and validate process settings and parameters through DOEs and SPC. Monitor critical variables.

- Implement gage R&R, capability studies, defect audits and other quality best practices.

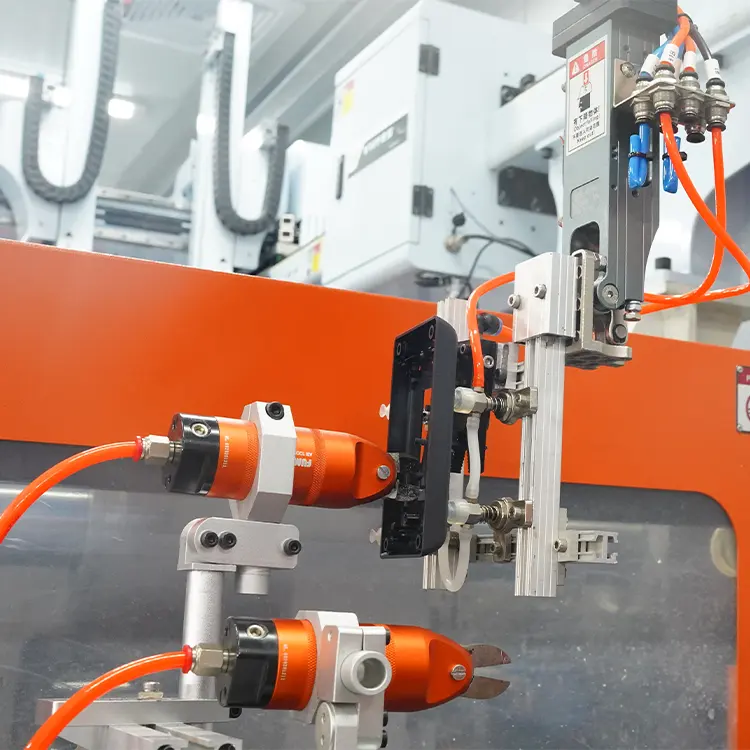

- Utilize automation and robotics for precision.

- Ensure material traceability and use approved materials.

- Regularly review and update SOPs based on feedback and process improvements.

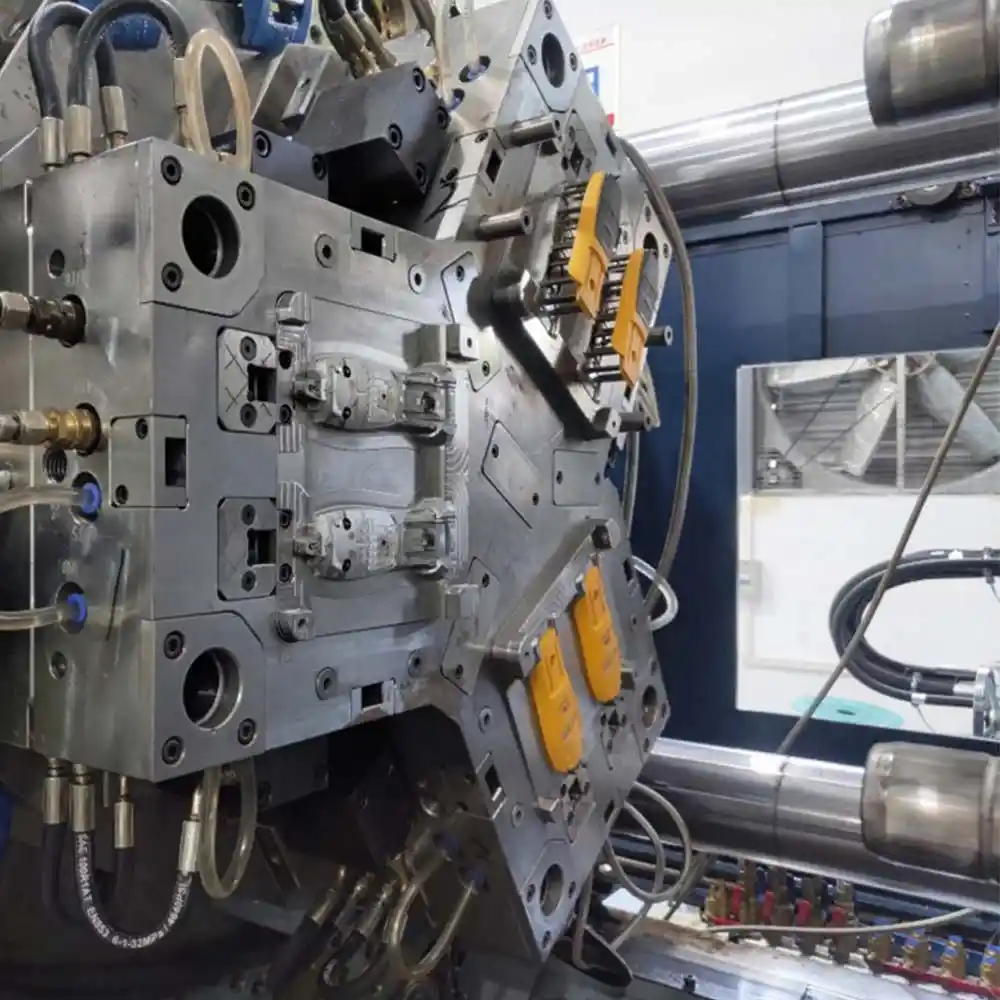

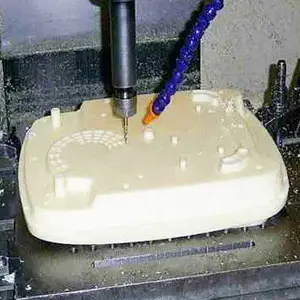

Technology and Equipment

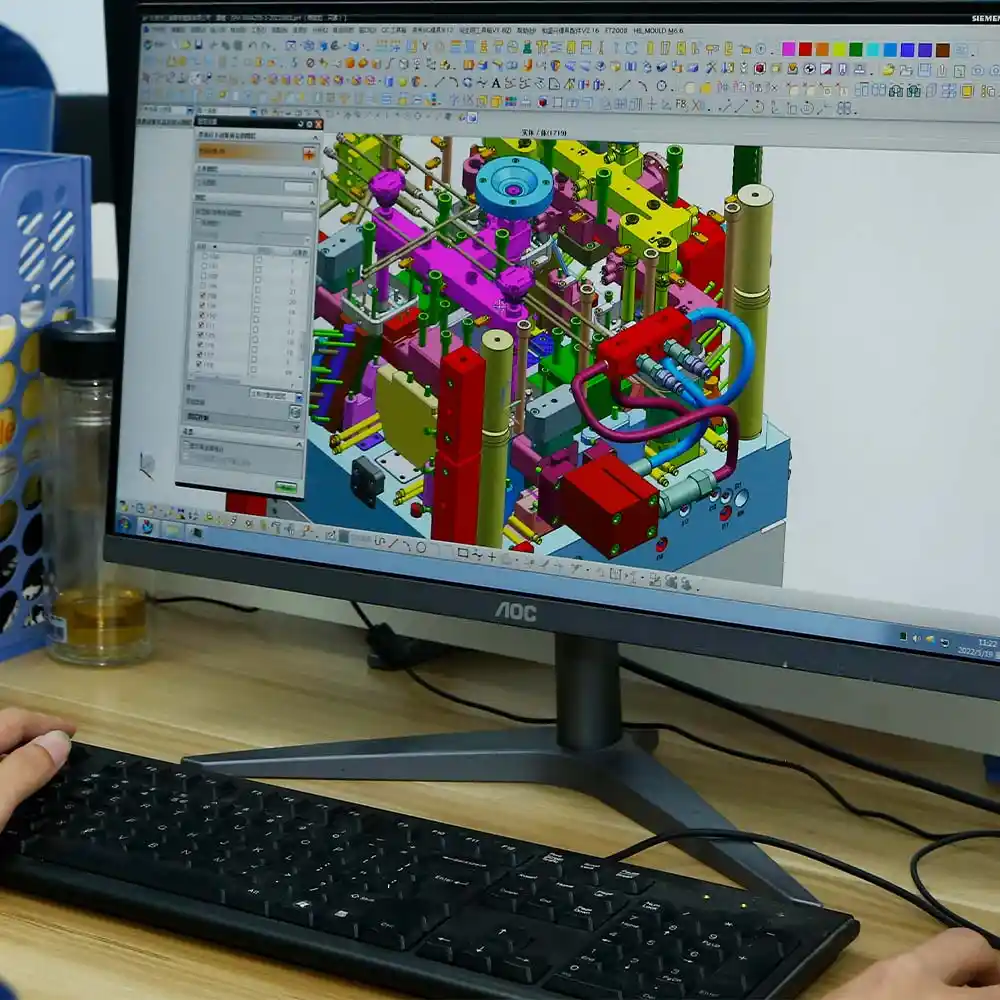

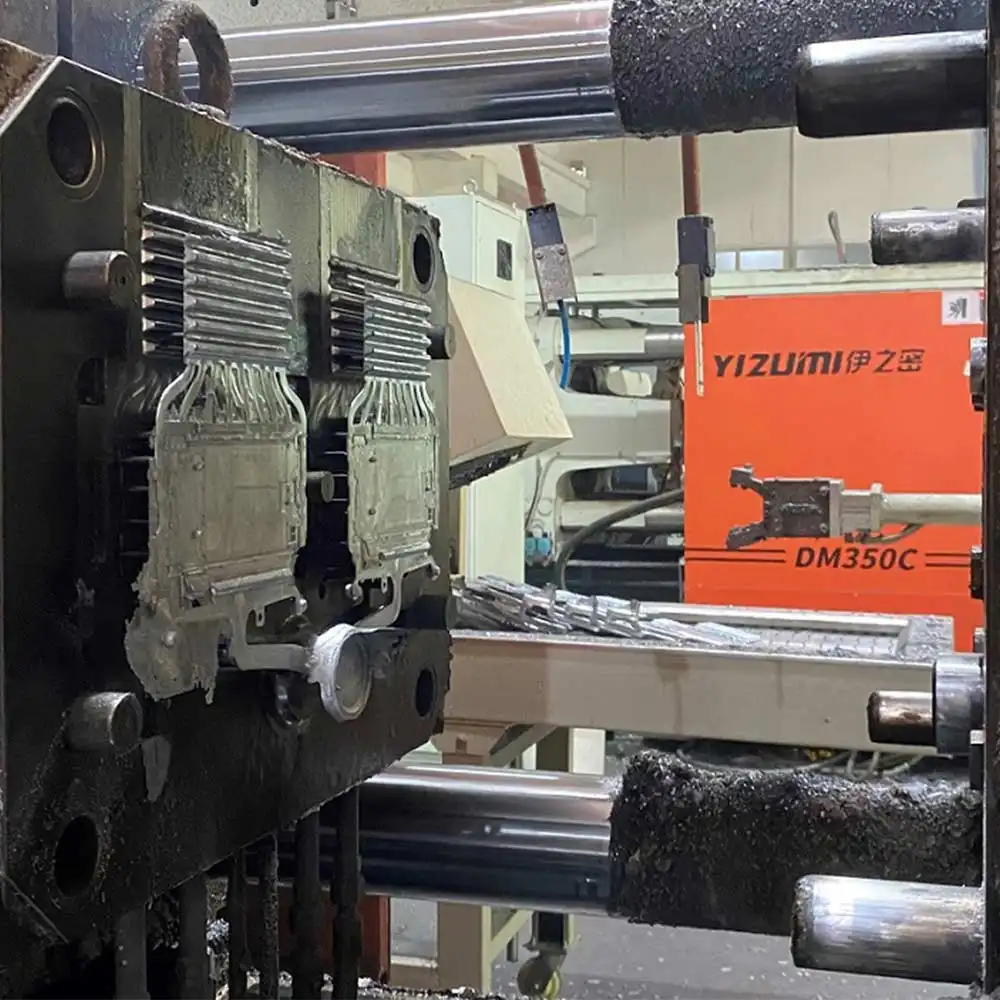

GPMFG is well-prepared to provide sizable amounts of injection molding parts promptly. In-house molds Development and Machining capability,32 injection molding machines from 50 to 800 tons.

- Over 20 years of experience in design and technical teams

- 32 injection molding machines from 50 to 800 tons

- Minimum Size:3x3x3mm Min & Part Tolerance: ±0.03mm

- Insert Molding, Overmolding, 2K/3K-Shot Injection Molding

- Experience with over 100 different OEM products

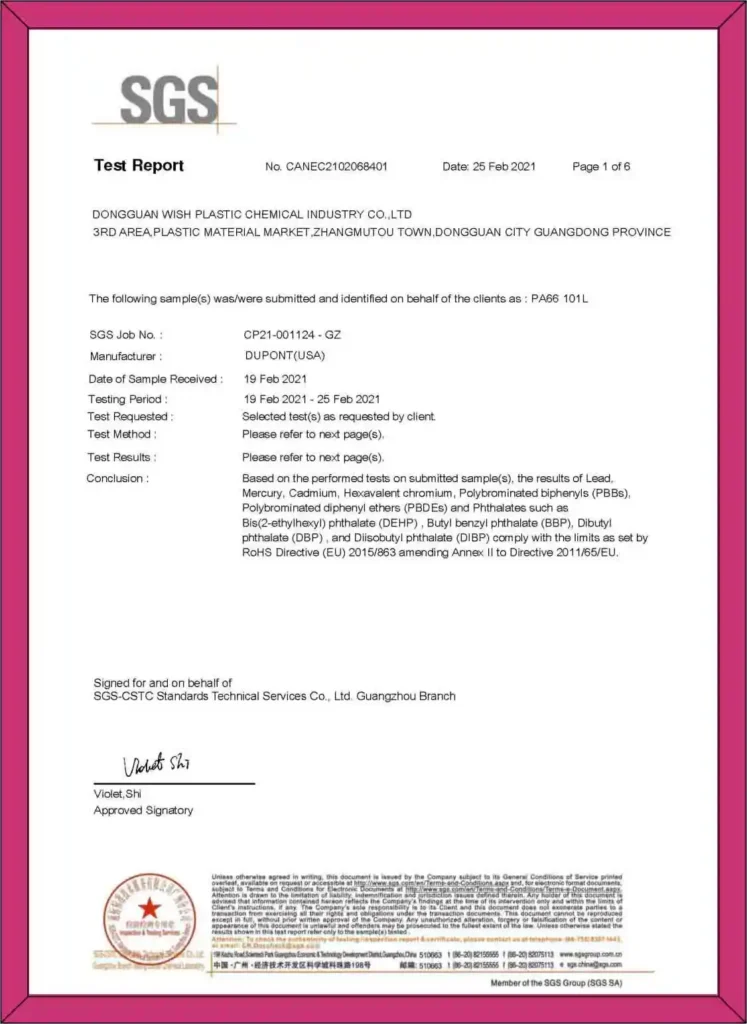

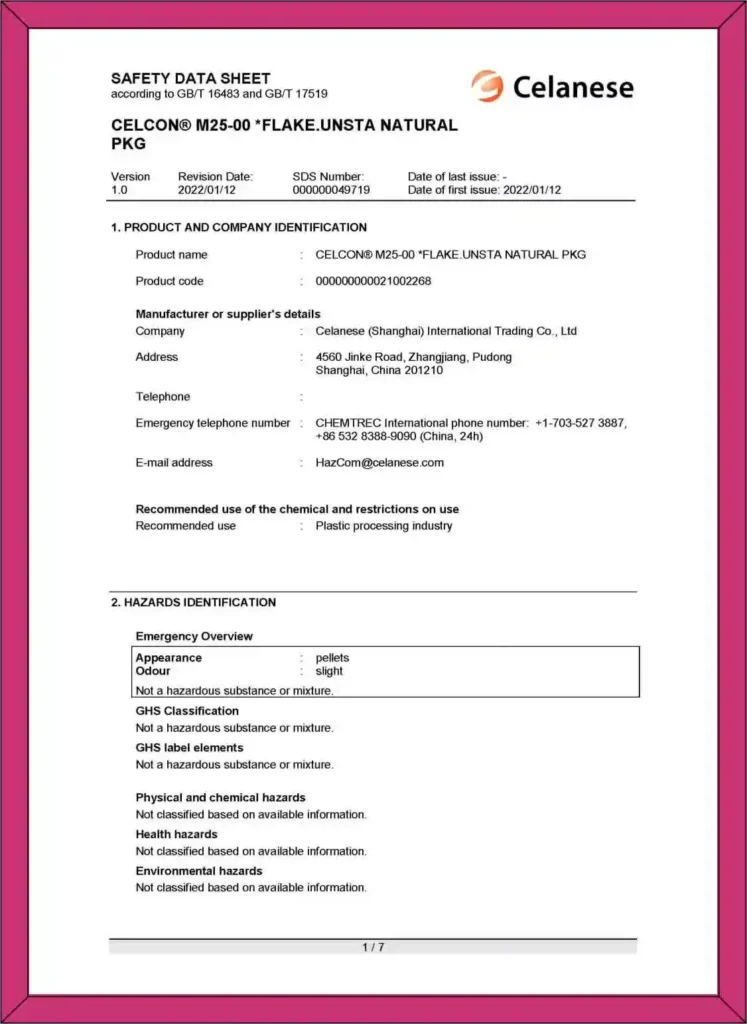

More material options

Different projects may require specific materials. OEM injection molding manufacturers should offer a range of materials to meet customer requirements for durability, strength and other properties.

- ABS

- ABS+PC

- HDPE

- HIPS

- LCP

- Nylon

- PPA

- PPS

- PS

- PBT

- PC

- PE

- PEI

- PET

- PMMA

- POM

- PP

- SAN

- LDPE

- PVC

- TPR

- TPU

Full range of finishing services

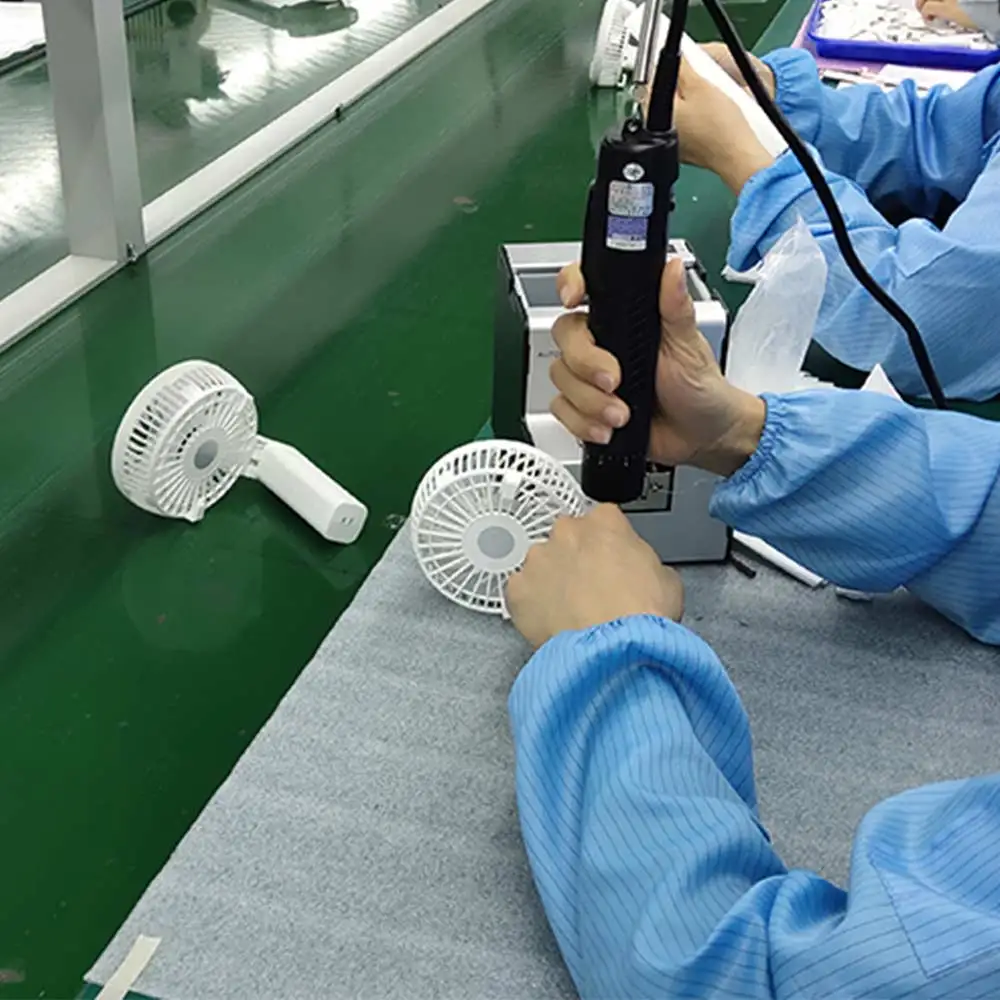

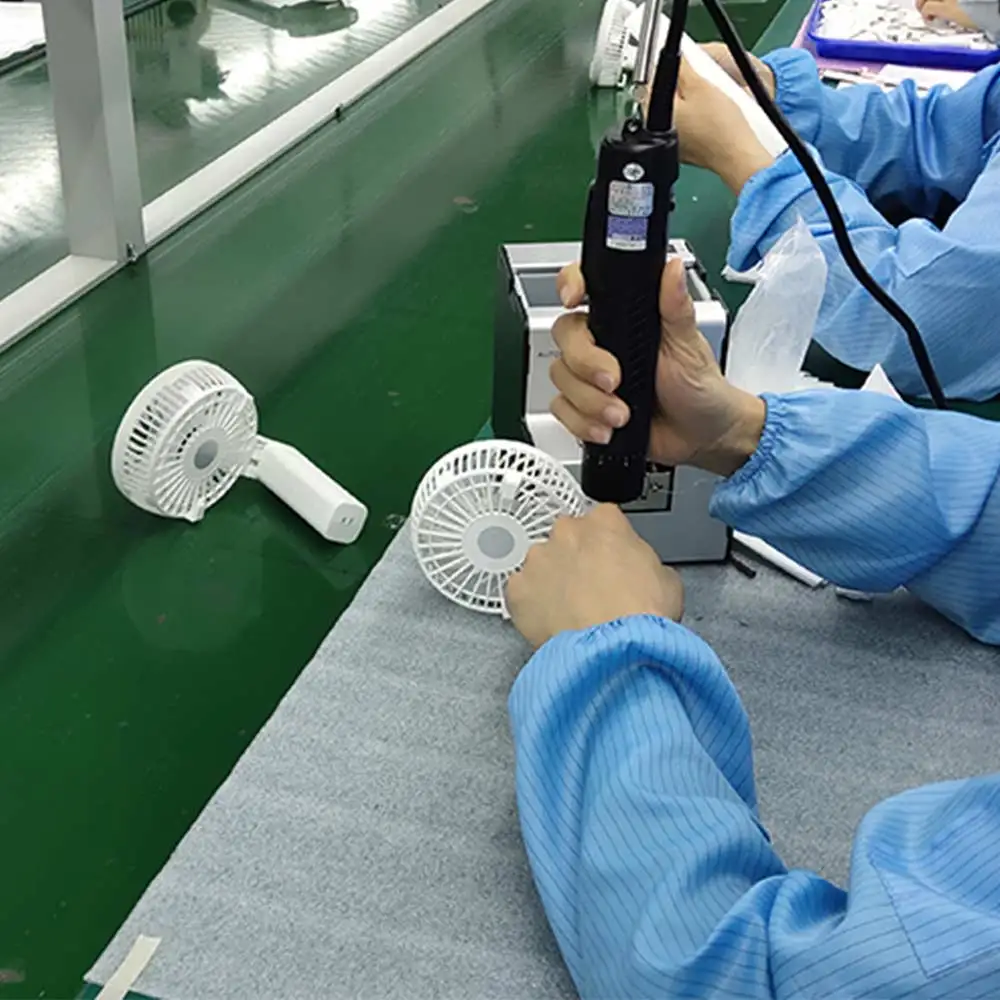

Assembly and Shipping

We have produced and assembled over 100 products for shipment to over 60 different countries.

- Over 20,000 finished products containing customer components are assembled daily.

- Dedicated packaging lines provide kitting, labels, specialty bags, gift boxes and other customized packaging.

- An established transportation network provides delivery and tracking in over 60 countries.

- We protect intellectual property by signing confidentiality agreements and not retaining or disclosing customer data or designs.

One-stop OEM solution - Service Process

As an injection molding manufacturer, we understand the importance of high-quality parts that meet your exact specifications. That’s why we offer comprehensive OEM services to handle every step of the production process, from design to delivery.

Material Selection

Confirm the surface of the part

DFM analysis & improvement

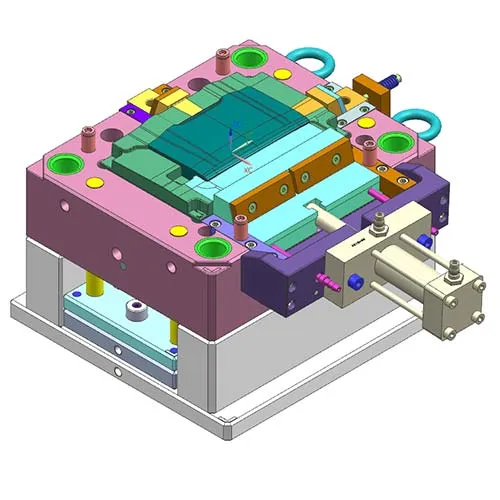

Mold Design

Mold Making

Making Smaples

Product test and approved

Production

Product Assembly

Packaging and delivery

Outstanding OEM Cases

Case 1: Safety Helmet

About the Product

Service scope: Plastic tool manufacturing and plastic injection molding

Tool life: 500,000 injections

Tool Material: P20 steel

Product Material: High-impact ABS

Post-processing: Pad printing

About the customer

The customer is a renowned construction equipment manufacturer based in Germany. They specialize in producing safety equipment and have a strong reputation for delivering high-quality products. The customer has chosen our company, GPMFG, as their manufacturing partner due to our expertise in plastic tooling and injection molding.

About the request

The helmet shell needs to be made of high-impact ABS, ensuring durability and resistance to impact forces.

The customer wants their company logo and safety certifications to be prominently displayed on the helmets. Therefore, pad printing is required to apply these markings accurately.

How to serve

For this project, we will design and manufacture two injection molding tools: one for the helmet shell and another for the internal components. The helmet shell will be made from high-impact ABS, which offers excellent impact resistance and toughness. The tooling material chosen for this project is P20 steel, known for its durability and suitability for high-volume production. Additionally, we will perform plastic injection molding to produce the helmet shells and internal components. Finally, we will utilize pad printing to apply the customer’s logo and safety certifications onto the helmets, ensuring a professional and branded appearance.

Case 2: Digital Intercom Plastic Tooling

About the Product

Service scope: Plastic tool manufacturing and plastic injection molding

Tool life: 800,000 injections

Tool Material: H13 steel

Product Material: ABS, PC

Post-processing: Painting

About the customer

The customer is a leading technology company headquartered in the United States and specializing in communication systems. They were impressed with our ability to meet stringent quality standards and adhere to project schedules in the past. This time, they needed our assistance for their new product components.

About the request

The housing and internal parts need to be made of durable and high-strength plastic, capable of withstanding frequent usage and environmental conditions.

The plastic housings should have a high-quality paint finish to match the aesthetics of the overall product design.

How to serve

We will manufacture the required plastic injection molding tools for the digital intercom project, including the main housing, button panels, and internal components. These tools will be made using H13 steel, known for its high hardness and heat resistance. The housing and internal parts will be manufactured using ABS and PC materials, ensuring durability and strength. Additionally, we will provide post-processing services, specifically painting, to achieve a premium finish on the plastic housings. The paint will be carefully selected to match the desired aesthetic requirements of the digital intercom system.

About GPMFG

Professional OEM Service - stable & Easy

GPMFG is a China-based OEM manufacturer offering comprehensive manufacturing solutions. With expertise in mold making, injection molding, die casting, and silicone molding, we provide end-to-end services including design, prototyping, manufacturing, assembly, and shipping. Our skilled team and advanced technology ensure high-quality products for various industries. Trust GPMFG for efficient, reliable, and integrated manufacturing capabilities.

- Rapid turnaround: Delivering 100,000 units in 3 weeks.

- Cost-effectiveness: Achieving 45% cost savings on part production.

- High precision: Tolerances as low as ±0.05mm.

- Strong quality control: Defect rate below 0.1%.

International certifications

Other in-house manufacturing capabilities

At our state-of-the-art manufacturing facility, we have the ability to turn your concept into reality. With our extensive OEM capabilities, we specialize in creating high quality products that meet your specifications and requirements. Whether it’s complex molds, intricate plastic parts, durable die-cast components or flexible silicone rubber molds, our team has the expertise to deliver superior results.

Mold Manufacturing

We create dependable molds for high-quality customized parts ensuring precision, fast production, competitive pricing, and reliable outputs.

Injection Molding

GPMFG is well-prepared to provide sizable amounts of injection molding parts promptly. In-house molds Development and Machining capability,32 injection molding machines from 50 to 800 tons.

Die Casting

We offer top die casting services using 24 machines from 80 to 400 tons, with in-house mold development, machining capabilities to deliver high quality products and excellent customer service.

Silicone Rubber Molding

GPMFG provide efficient, reliable, and high-quality silicone rubber molding solutions for your products.From Tooling/Molds design,manufacturing to molding productiong.

What they say about GPMFG

Don’t just take our word for it. Our esteemed customers have consistently praised our OEM services and the value we bring to their businesses.

Rick M.

The attention to detail, technical expertise and professionalism demonstrated by GPMFG makes them our preferred OEM partner. They go above and beyond our requirements and contribute significantly to our success.

Justin L.

Working with GPMFG on our OEM program has been a game changer. They truly understood our vision and brought it to life. They consistently deliver a top-notch product and their post-sale support is outstanding.

Professional OEM Service - Enhance Brand Effectiveness

We optimize the full range of manufacturing processes, all you need to do is provide drawings, and with our stable and fast OEM service process, all you need is a cup of coffee at home to get a high quality custom part that meets your standards.

- No Minimum Order Quantities

- Save 35-65% costs

- 40% reduction in delivery time