One-Stop Molds Manufacturing and Plastic Metal Components Solution

- Zinc & Al Die-Casting

- Precision CNC Machining

- Assembly and Test

- OEM Assembly Service

Prototype to products manufacturing services

Whether it’s a simple part or a complex finished mold, our comprehensive manufacturing capabilities can take it from design to finished product for you.

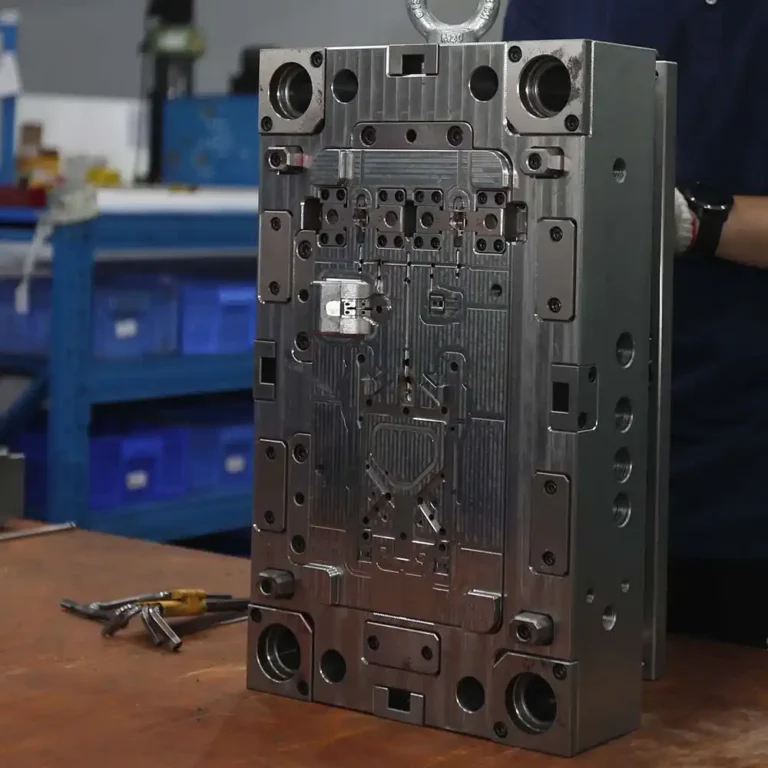

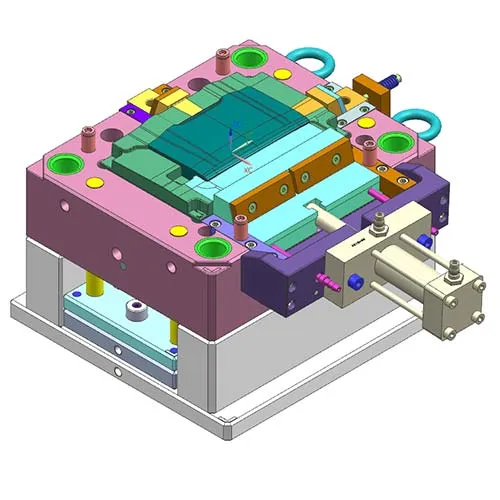

Mold Manufacturing

20 yrs experience in designing and manufacturing injection & die-casting molds, with over 300 sets of molds per year

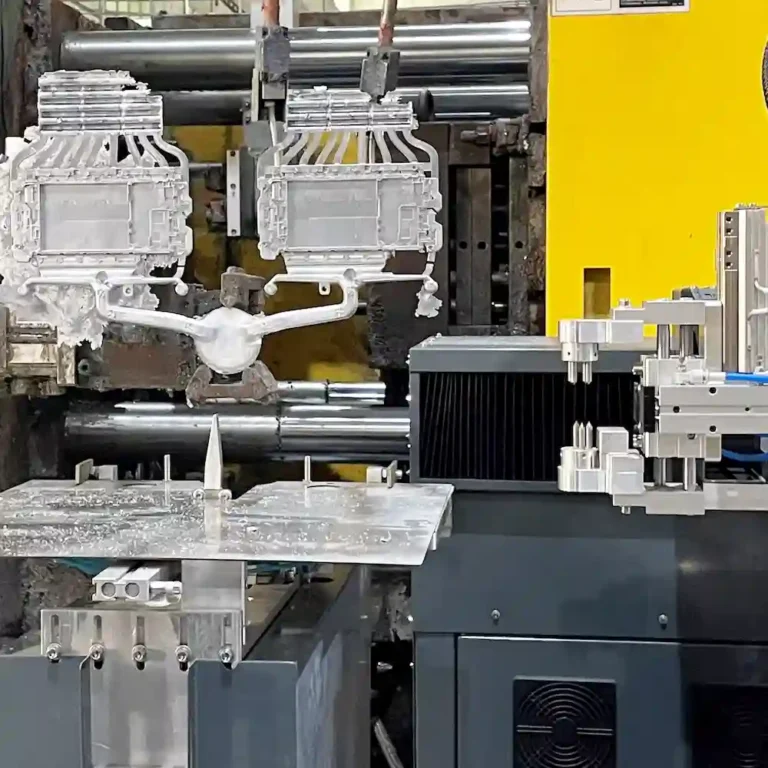

Injection Molding

Custom injection molding, overmolding, double-shot injection molding & 3k injection molding.

Die Casting

Supply Custom Zinc Alloy Die Casting&Aluminium Alloy Die Casting with Good mechanical properties

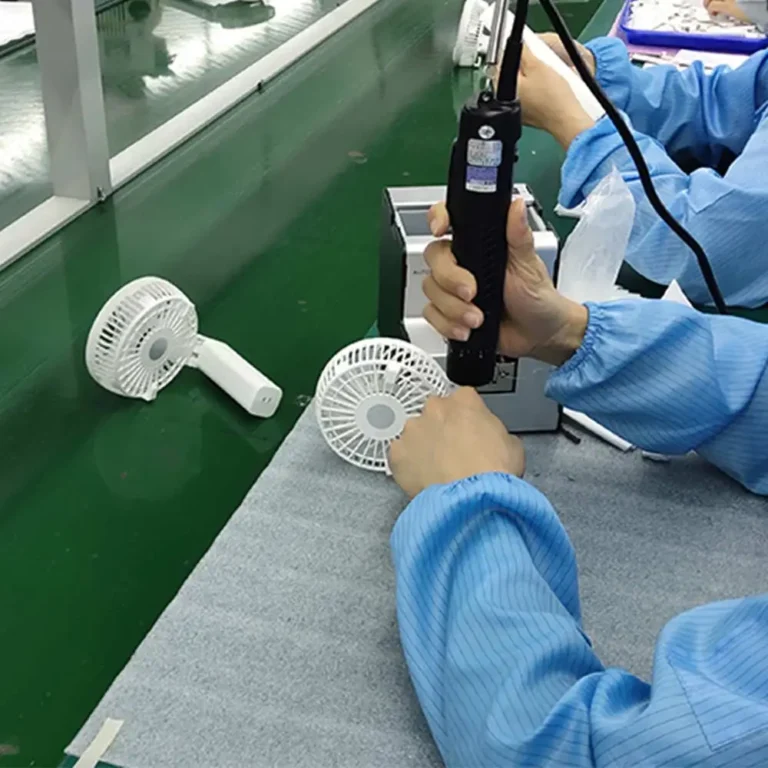

OEM & Assembly

Provide one-stop end-product services: Development, Parts manufacturing, Assembly, and Testing.

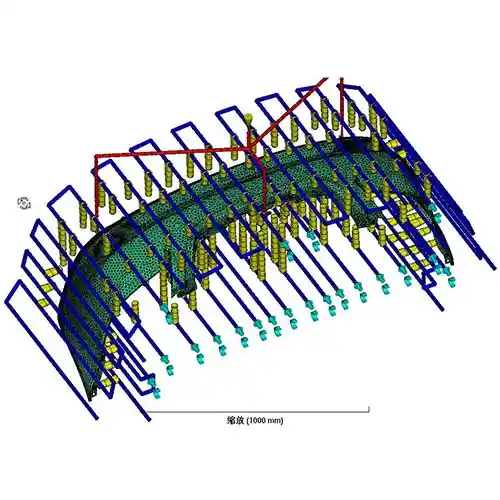

Development & Engineering

Our 20-person design team has over 10 years of experience in product design and development. We use the latest CAD and development tools to optimize your product design, avoid defects, improve quality, and give you a better, more cost-effective product.

- Parts 3D Model Design from samples if need

- Products/Parts Analysis.Issue DFM

- Tooling/Molds design

- Publish In-house 2D product drawing with Tolerance

- Publish SOP,SIP,BOM

- Check and accept Tooling/Molds and Fixtures

- Trial production and make samples

- Test Products

Prototyping, Machining, and Manufacturing Solution Provider

Opt for Gain Power Precision Mfg Limited, your premier manufacturing solution with over two decades of industry expertise. Ranging across diverse sectors, our adept design team offers precise guidance. Coupled with our cutting-edge manufacturing facility, we assure top-notch quality and timely delivery. Entrust us, and we pledge a cost-effective outcome.