Plastic Injection Molding Manufacturer

GPMFG is well-prepared to provide sizable amounts of injection molding parts promptly. In-house molds Development and Machining capability,32 injection molding machines from 50 to 800 tons.

- Products/Parts Analysis and Optimizing

- Tooling/Molds Development & Manufacturing

- Normal Injection Molding

- Insert Molding

- Overmolding

- 2K/2-Shot Injection Molding

- 3K/3-Shot Injection Molding

- Diverse Post processes available

INDUSTRIES SERVED

Consumer Electronics

GPMFG provides injection molding for personal electronic devices, smart home and IoT products, kitchen appliances, durable housings and enclosures, gaming peripherals and VR headsets.

- Products/Parts Analysis Issue DFM

- Tooling/Molds Design

- Publish SOP, SIP, BOM

Medical & Health care

GPMFG provides injection molding for personal beauty devices, fitness equipment, nursing care equipment, medical monitors, and ultrasonic equipment.

- Quick turn around

- Low-cost molding solution like prototype molds

- Full service. from design to final parts & assembly

Industrial & Manufacturing

GPMFG provides injection molding for, machine tools, industrial robots, automation parts, moving parts, replacement parts, industrial fixtures, pumps and accessories.

- Free raw material samples for chemical test

- Free resin pellets for chemical test

- Excellent control on part tolerance

Household

GPMFG provides injection molding for kitchenware, storage containers, toys, tableware, furniture components, bathroom accessories, furniture and more.

- Competitive unit pricing

- Secondary operation available: printing or labeling

- Molding production runs at 24/7

automotive industry

GPMFG provides injection molding for headlights,, instrument panels, bumpers, interior trim, dashboard components, engine parts, air filter housings and more.

- Flexible production scale

- Customized packaging

- Global logistics and distribution

Other Gear Parts

GPMFG also provides injection molding for production parts such as high-precision gears and gear components.

- Eco-friendly production processes

- Safe production environment

- Rapid prototyping

Electric power tool

Process: injection molding

Mold cavity:1

Cycle time:45s

Lead time:(30 days for 1st 5K)+(the lead time of material)

Customer Region: Canada

Material : POM , White color

Fan Accessories

Process: injection molding

Mold cavity:2

Cycle time:21s

Lead time:(20 days for 1st 5K)+(the lead time of material)

Customer Region: UK

Material : PA66+30%GF , Black color

Fire Truck Valve

Process: injection molding> annealing>CNC machining

Mold cavity:1

Cycle time:390s

Lead time:(45 days for 1st 5K)+(the lead time of material)

Customer Region: Australia

Material : Mixed POM , Nature color

Toilet Accessories

Process: injection molding

Mold cavity:1

Cycle time:45s

Lead time:(30 days for 1st 5K)+(the lead time of material)

Customer Region: Canada

Material : POM , White color

Oxygen Cylinder Handle

Process: injection molding>pad printing

Mold cavity:1+1

Cycle time:38s

Lead time:(10 days for 1st 5K)+(the lead time of material)

Customer Region: Germany

Material : PC , carbon black color

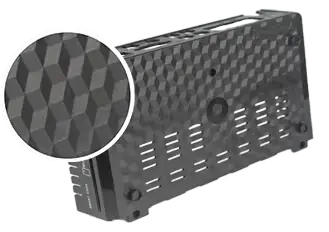

Air Intake Grid

Process: injection molding

Mold cavity:1

Cycle time:43s

Lead time:(30 days for 1st 5K)+(the lead time of material)

Customer Region: United Arab Emirates

Material : PP-TD30 , Black color

Cutting-edge injection molding services

Our unparalleled injection molding technology offers state-of-the-art machinery, which guarantees high-quality plastic products of varying sizes, from the smallest to the largest. Get your product made with excellence.

Normal Injection Molding

- Our scientific approach minimizes tolerance variability to under 1% and cycle time by 15% through rigorous process controls, automation, and cooling optimization.

- It is suitable for high volume general purpose parts such as connectors, caps, housings .

Insert Molding

- Our insert molding integrates components into plastic. Advanced process controls maintain tight dimensional tolerances.

- Simulations optimize gate location for maximum weld strength. X-ray inspection ensures quality.

Overmolding

- Our overmolding process delivers 20% stronger bonding than industry standards, reducing delamination risk for keypads, grips and handles.

- Optimized simulations minimize flash while tight process controls maintain part tolerances.

2K/2-Shot Injection Molding

- Our engineered two-component molding achieves bond strength exceeding industry averages by 15%, reducing separation failures in parts like soft-grip handles.

- Precisely controlled sequential injection and overmolding maintains dimensional tolerances under 1% for perfect fit between two different resins.

3K/3-Shot Injection Molding

- Our 3-shot molding precision blends three resins in a single part, with process controls ensuring ±0.3% material tolerance for precise fit.

- Advanced simulation optimizes adhesion and minimizes meld lines, suitable for intricate uses such as gaskets with varying areas or insulated cores in electrical components

Gas-Assisted Injection Molding

- Our gas-assisted molding injects nitrogen or carbon dioxide to form internal voids, cutting sink marks and warping in items like auto interior trim by over 20%.

- We use fluid dynamics simulations to enhance gas channel design, achieving uniform part walls under 3mm.

Finishing Services

Surface Finish

Capabilities to texture the mold according to any VDI texture, SPI finish, Yick Sang and MoldTech Texture.

- Silk & Pad Printing

- Electroplating

- UV Coating

- Hot stamping

- Laser Engraving

- Others

Texture / Grain

Processed on outer surfaces of the parts

Regular Polish

Processed on regular outer surfaces or most inner surfaces

Mirror Polish

Processed on transparent or chrome-plating parts

Silk & Pad Printing

The printing process transfers a 2D image to a 3D substrate. The indirect process transfers the image from the silicone pad to the final substrate material.

Pros:

- Many color choices

- Wide range of application

- Low cost

Cons:

- Curved surface printing is difficult

- Friction resistance test results are mediocre

Electroplating

Electroplating is a surface treatment process where a thin metal layer is deposited electrochemically onto a substrate, creating a shiny finish.

Pros:

- Enhances weather resistance

- Provides excellent surface finish

- Improves durability

Cons:

- High process requirements may lead to higher costs.

- Requires proper disposal of wastewater and exhaust.

UV Coating

UV coating is a surface treatment process in which a liquid coating is applied to a plastic substrate and then cured using ultraviolet light, creating a durable protective layer.

Pros:

- Enhances scratch and abrasion resistance

- Provides a high-gloss, attractive finish

- Offers chemical and solvent resistance

Cons:

- Requires specialized UV curing equipment

- Limited coating thickness

Hot stamping

The process of transferring metallic foil material (usually gold foil) on the surface of plastic by hot pressing technology, so that the surface of the product presents a glossy texture.

Pros:

- Metallic luster surface

- Customized unique pattern logo

- Durable, not easy to wear and tear

Cons:

- Suitable for some plastics.

- Higher cost, especially in small batch production.

Laser Engraving

Using a laser to etch a fine pattern or text on the surface of a material.

Pros:

- High fineness, suitable for complex patterns.

- Suitable for a wide range of materials.

- Resistant to abrasion and long lasting.

Cons:

- High cost per unit.

- Limited color options.

Selection of materials for injection molding

Rigid injection molding material

Rigid injection molding material refers to a type of plastic that is designed to be hard and inflexible. It is commonly used for manufacturing products requiring rigidity and durability.

ABS - Acrylonitrile Butadiene Styrene

ABS material is currently the largest output, the most widely used polymer, ABS can organically unify the various properties of PS, SAN, BS, and has the excellent mechanical properties of tough, hard, rigid phase equilibrium. In general, ABS is a very versatile thermoplastic engineering plastics.

Advantages

- Mechanical properties and thermal properties are good

- High hardness

- The surface is easy to gold plating

- Fatigue resistance and stress cracking resistance,

- High impact strength

Disadvantages

- ABS is easily affected by solvent and stress cracking.

- ABS weather resistance is poor, susceptible to the action of sunlight, discoloration, brittle

ABS+PC - ABS + Polycarbonate Alloy

PC/ABS plastic is a new type of thermoplastic plastic, it is rigid and toughness, with high impact strength, high dimensional stability and a wide range of temperature, good electrical insulation performance and heat resistance, non-toxic and anti-ultraviolet (UV) properties.

Advantages

- High impact strength, chemical stability, good electrical properties.

- High impact resistance, high heat resistance, flame retardant, enhanced, transparent and other grades.

- Electrical insulation is good.

Disadvantages

- The thermal deformation temperature is low.

- Combustible.

- Poor weather resistance.

HDPE - High Density Polyethylene

HDPE is an opaque white wax-like material, the specific gravity is lighter than water, the specific gravity is 0.941~0.960, soft and ductile, but slightly harder than LDPE, also slightly elongate, non-toxic, tasteless. It is the product of polymerization under low pressure under the catalysis of Ziegler catalyst, so high density polyethylene is also known as low pressure polyethylene.

Advantages

- Its high strength, high-temperature resistance, corrosion resistance, non-toxic, wear resistance, and other characteristics.

- Impact resistance, cracking resistance, aging resistance, corrosion resistance, and a series of advantages.

- It has good machinability and heat sealing properties

Disadvantages

- Easy aging and cracking are not as good as LDPE.

- Small transparency, the poor barrier to air.

- Difficult to print, can not be electroplated, dull surface.

LCP - Liquid Crystal Polymer

LCP is a kind of high molecular material composed of rigid molecular chains. Under certain physical conditions, it can appear both liquid mobility and crystal physical properties of anisotropic state (this state is called liquid crystal state). LLCP is used to produce fiber,TLCP can be injection molding, extrusion molding and so on.

Advantages

- Good weather resistance and radiation resistance.

- It has excellent flame resistance.

- Corrosion resistance.

Disadvantages

- The mechanical strength is worse than high-temperature nylon.

- Poor strength of binding wire.

- Poor dyeing property.

- The appearance is dull and has flow marks.

Nylon 6 - Polyamide 6

It has high crystallinity, obvious melting point, large surface hardness, abrasion resistance, small friction coefficient, self-lubricity and silencing. Good low temperature performance, a certain heat resistance (can be used below 100 degrees). Non-toxic, odorless, no mildew, self-quenching, good weather resistance, but poor dyeing.

Advantages

- A combination of strength and durability, excellent rigidity, and heat resistance.

- Good processing, excellent fluidity, and thermal stability make the material processing conditions more relaxed, so injection parts are miniaturized.

- High thermal stability, can be up to 270 degrees wave peak solder without hanging tin.

Disadvantages

- Easy bibulous

- Poor light fastness

- Injection molding technology requirements are more strict

- Resistant to acids and oxidants

PBT - Polybutylene Terepthalate

PBT is a tough, heat-resistant thermoplastic polyester. It has high heat resistance, durability, low friction, and resists water, alkalis, acids and oil. However, it is susceptible to halogenated hydrocarbons and hydrolysis. Glass fiber reinforced PBT products can warp due to uneven shrinkage.

Advantages

- It has high rigidity and hardness.

- Good heat resistance.

- Good appearance gloss function.

- Fast crystallization speed, good fluidity, excellent molding.

- Good resistance to chemicals, solvents and weather.

Disadvantages

- Poor stability at high temperatures.

- It burns easily.

- Water and alkaline resistance.

PC - Polycarbonate

PC is an amorphous thermoplastic resin with excellent overall properties including electrical insulation, dimensional stability, chemical resistance, high strength, heat resistance, flame retardancy, and coloring ability. It is widely used in everyday products and has low cost due to large-scale production and easy processing.

Advantages

- Excellent electrical insulation, extensibility, size stability and resistance to chemical erosion.

- High strength, heat resistance and cold resistance.

Disadvantages

- Lack of hardness, easy to scratch.

- Resistant to strong acids, alkalis, ultraviolet light, weak acids, and neutral oil.

PE - Polyethylene

PE (polyethylene) is an odorless, non-toxic plastic with excellent low-temperature resistance, chemical stability, and electrical insulation properties. It has low water permeability but high air permeability. PE is flammable with low smoke emission. Its non-polar surface makes bonding and printing difficult without surface treatment. Branched PE has poor resistance to photodegradation and oxidation.

Advantages

- Lightweight, good corrosion resistance (no need for corrosion protection).

- It has good flexibility, can be laid along with the terrain bending in construction, and has certain anti-seismic and anti-settlement abilities.

- It has good welding performance and a convenient connection.

- Long service life, at least 50 years.

Disadvantages

- Very sensitive to environmental stress, poor heat resistance aging.

PET - Polyethylene Terepthalate

PET is a highly crystalline polymer with excellent physical/mechanical properties over a wide temperature range up to 120°C. It has good electrical insulation, creep resistance, fatigue resistance, friction resistance and dimensional stability, but poor corona resistance.

Advantages

- Good mechanical properties, impact strength is 3~5 times of other films, good flexability.

- With excellent high temperature resistance, low temperature performance

- High transparency, can block ultraviolet rays, good gloss.

- Non-toxic, tasteless, good health and safety, can be directly used in food packaging.

Disadvantages

- The corona resistance is poor.

- No heat – resistant water immersion, no alkali resistance.

PMMA - Acrylic

PMMA (Polymethyl methacrylate), also known as acrylic or Plexiglas, is a transparent plastic with high optical clarity, impact strength, and ease of fabrication. It is widely used for sheets, lenses, signage, automotive parts, and medical devices due to its durability and resistance to UV, weathering, and some chemicals.

Advantages

- High transparency (high transmittance, transmits light that other transparent materials cannot pass through, higher than glass, light transmission range).

- Easy to process.

Lightweight. - High mechanical strength.

- Withstand outdoor aging.

- It has unique electrical properties.

Disadvantages

- Low surface hardness, resistant to scratch.

- Easy to fade.

- Production is difficult and costly.

- It is easily removed by thermal expansion and cold contraction.

- Poor polishing effect.

POM - Acetal

Polyformaldehyde is a highly crystalline linear polymer with high density and crystallinity up to 85% due to its flexible molecular chains and lack of side chains. Even after rapid cooling, its crystallinity remains over 65%. Completely amorphous form requires cooling to -100°C.

Advantages

- It has high mechanical strength and rigidity.

The highest fatigue strength. - Good environmental resistance and organic solvent resistance.

- Strong resistance to repeated impact.

- Wide range of temperature (-40 ° -120 °).

- Good electrical performance.

- Good resilience.

- It has a self-lubricating properties and good wear resistance.

Disadvantages

- There is no self-extinguishing.

- Forming shrinkage rate.

PP - Polypropylene

PP is a thermoplastic resin made by polymerization of propylene. Usually translucent colorless solid shape, non-toxic and odorless. PP itself is non-toxic, so it can be widely used as plastic bags, plastic bottles, plastic film and so on processing, but polypropylene plastic after processing, will add some plastic fillers, plastic pigments, plasticizers and other chemical components, and these chemical additives, is toxic.

Advantages

- Good mechanical properties, except impact resistance, other mechanical properties are better than

- polyethylene, good molding performance.

- It has high heat resistance.

- Good chemical properties, almost not water absorption, and the vast majority of chemical drugs do not react.

- Pure texture, no toxicity.

Good electrical insulation.

Disadvantages

- Product cold resistance is poor, low temperature impact strength is low.

- Products are susceptible to aging by light, heat and oxygen during use.

- The colouring is not good.

- Easy to burn.

- Poor toughness, high static electricity, poor dyeing, printing and adhesion.

SAN - Styrene Acrylonitrile

SAN (styrene-acrylonitrile copolymer) is a colorless, transparent thermoplastic resin. It has high temperature resistance, gloss, chemical resistance, hardness, rigidity, dimensional stability and strength. SAN is produced by suspension or emulsion polymerization of styrene and acrylonitrile monomers. Its transparency makes it suitable for manufacturing clear plastic products.

Advantages

- High transparency, not easy to crack, good impact strength.

- Non-toxic, can be used by contact, but will melt after reaching a certain temperature, not suitable for daily heating with microwave oven.

Disadvantages

- Easy aging, poor weather resistance, easy deformation.

Flexible injection molding materials

Flexible injection molding materials are pliable polymers used for manufacturing products requiring elasticity, such as phone cases, tubing, and toys. These materials can stretch and bend without breaking or cracking.

LDPE - Low Density Polyethylene

LDPE, THE OLDEST MEMBER OF THE POLYETHYLENE FAMILY OF RESINS, WAS first commercially PRODUCED as a wire WRAPPER in the early 1940S. LDPE integrated some good properties: transparent, chemical, sealing ability is good, easy to form processing.

Advantages

- It has good softness, extensibility, electrical insulation and transparency.

- Easy workability and constant air permeability.

- Its chemical stability is good, and alkali resistance, and resistance to general organic solvents.

- Easy to burn.

Low-temperature resistance.

Disadvantages

- Poor mechanical strength, transparency and aging resistance

- Heat resistance and resistance to light aging is poor, easy to aging decomposition and discoloration in sunlight or high temperature.

PVC - Polyvinylchloride

Polyvinyl chloride (PVC) is an economical, versatile material that can be used in construction and construction, medical, electronics, automotive and other fields. Products include pipes and paints, blood bags, pipes, wires, cable insulation, windshield components, etc.

Advantages

- Polysulfone has high hardness and impact strength, non-toxic, good heat and cold resistance to aging.

- It is mainly to improve its impact strength and elongation, solvent resistance, environmental resistance, machining performance and electroplating.

- It has good moisture resistance and wear resistance.

- Rugged, reliable and light.

Disadvantages

- The cost is higher.

- Thermal stability is not good, hard and embrittlement at low temperatures, but easy to soften and relax at high temperatures.

- High temperatures release dioxin acid gas.

- Poor machining performance.

TPR - Thermo Plastic Rubber

TPR is a thermoplastic elastomer based on styrene-butadiene rubber, with added resins, fillers, oils and additives. It has rubber-like elasticity without vulcanization and can be directly molded using thermoplastic processing methods.

Advantages

- Weather resistance and aging resistance are general.

- Rubber resilience and good wear resistance, skid resistance, and shock absorption performance are excellent.

Disadvantages

- Not resistant to high temperature.

TPU - THERMOPLASTIC POLYURETHANE ELASTOMER

TPU is a thermoplastic polyurethane elastomer with a wide hardness range. It has good abrasion resistance, oil resistance, transparency, elasticity and is used in consumer goods, sports, toys and decorations. TPU combines high tension, toughness, aging resistance with being an environmentally friendly material.

Advantages

- Good elasticity and wear resistance.

- The bearing capacity, impact resistance and shock absorption performance are outstanding.

- Outstanding cold resistance.

- Good machining performance.

- Low-temperature performance.

- High temperature and oxidation resistance.

Disadvantages

- Not resistant to strong polar solvents and strong acid-base media, easy to deformation and yellowing.

Our Factory

Professional Manufacturer

Mold CNC workshop

- 40+ vertical and horizontal machining centers

- ±0.03mm tolerance & SPI B1 finish

Mold EDM workshop

- 10+ Sinker EDM Machines

- Tolerance ±0.005mm & Finish below Ra 0.1μm

Mold Wire-cut workshop

- auto-thread wire EDM technology

- Precise orbital cutting heads

Mold Assembly Department

- Components positioned accurately up to 0.02mm.

- Protocols ensure quality and consistency.

injection molding Workshop

- 32 injection molding machines from 50 to 800 tons

- T1 Samples As Fast As 2 Weeks

Quality Department

- Measure with CMM and optics.

- Testers for material strength and durability.

FAQs for Injection Molding

What is injection molding?

We are a factory. We provide you with one-stop service from mold design to finished product.

What are the steps of injection molding?

- Clamping: the mold is closed tightly.

Injection: melted plastic is injected into the mold cavity. - Dwelling: the plastic is allowed to cool and solidify within the mold cavity.

- Cooling: the mold is cooled to ensure the plastic is set.

- Ejection: the mold is opened and the finished product is removed.

- Post-processing: additional finishing steps may be taken, such as trimming or painting.

What are the advantages of injection molding?

- High volume production capability: Injection molding is ideal for producing large quantities of products in a short amount of time.

- High precision and repeatability: Injection molding can produce parts with very tight tolerances and consistent quality, ensuring that every part is identical.

- Wide range of materials: Injection molding can be used with a wide variety of materials, including thermoplastics, thermoplastic elastomers, and even some metals.

- Design flexibility: Injection molding can produce complex and intricate shapes with ease, thanks to the use of molds that are custom-made for each part.

- Low labor cost and high efficiency: Injection molding machines can be fully automated, requiring minimal manual input, which saves time and labor costs.

What are the disadvantages of injection molding?

- High upfront tooling cost: The cost of designing and manufacturing molds can be high, especially for smaller production runs.

- Limited part size: Injection molding is typically limited to producing relatively small to medium-sized parts.

- Difficulty with certain materials: Some materials, such as those with high melting points or those that are prone to warping, can be challenging to work with in injection molding.

- Environmental impact: Injection molding produces waste material and can contribute to pollution if not managed properly.

- Long lead time: The time required to design and manufacture molds can result in a longer lead time for production when compared to other manufacturing methods.

How long does injection molding last?

The lifespan of an injection molding mold largely depends on various factors such as the material used, molding conditions, molding frequency, maintenance, and care. However, most injection molding molds can last for thousands of cycles with proper maintenance and care.

For example, aluminum molds have a shorter lifespan of around 10,000 cycles before experiencing wear and tear, while steel molds last much longer, up to 100,000+ cycles. However, this is just an estimated range, and the actual lifespan can vary based on the factors mentioned before.

What do I need to pay attention to in injection molding?

In injection molding, it is important to pay attention to the following factors:

- Material selection: Choose the right raw material based on the product’s properties and requirements.

- Mold design: A well-designed mold can reduce defects and improve efficiency.

- Injection molding process parameters: Proper temperature, pressure, and injection speed all affect the quality of the product.

- Quality control: Testing and inspection at every stage can help ensure quality products.

- Supplier selection: Select a reputable and experienced supplier who can provide quality products and services.

Is injection molding cheaper in China?

Injection moulding in China can be up to 50% cheaper than in Europe and the US, depending on various factors such as labour costs, production volumes and logistics. China’s abundant supply of raw materials and large manufacturing capacity can translate into cost savings for companies seeking to produce plastic parts through injection moulding.

Are you a factory or a trading company?

We are a factory. We provide you with one-stop service from mold design to finished product.

What equipment is used in the plastic injection molding process?

We have 32 injection molding machines, including 160T 2-shot injection molding machine and 530T 3-shot injection molding machine.

What size parts can you produce?

We produce injection molding machines with a clamping force of 50-530 tons. Sizes range from very small to very large.

What are your tolerances?

We can accommodate your desired service from our wide range of secondary options including assembly, milling, drilling, CNC machining, painting, tapping, hot stamping, hot fusing, hot inserting, ultrasonic welding, ultrasonic inserting, trimming, sorting, and special packaging.

What secondary services are available for my injection molded products?

We can accommodate your desired service from our wide range of secondary options including assembly, milling, drilling, CNC machining, painting, tapping, hot stamping, hot fusing, hot inserting, ultrasonic welding, ultrasonic inserting, trimming, sorting, and special packaging.

What is your standard delivery time?

Numerous elements contribute to the duration of part lead times, such as the availability of materials, the volume of parts required, the availability of Generally, the lead times for reordering parts are around 1-2 weeks. While simple molds can be finished in a few weeks, complex molds, such as those with high cavitation, hardened steel, or multi-action tools, may take several months to complete.

Translated with www.DeepL.com/Translator (free version)

How will my parts be shipped?

Parts are shipped domestically and internationally depending on the requirements of our customers. Some customers prefer to use their own trucks or arrange their own pickups through a shipping agent. Arrangements are also made to ship via freight companies, courier services, UPS or Fed-Ex.

Do you provide inspection reports?

Yes, we do. All parts go through our quality control department before they are shipped. They will be inspected according to the documentation. Inspection reports will be kept for 3 months. We can provide them if needed. For mass production, we only provide random inspection reports.