About GPMFG

Your Trusted Partner for Prototyping and Manufacturing

Your trusted mold making & parts manufacturing supplier in China

Gain Power Precision Mfg Limited (GPMFG) is a leading provider of plastic injection molding, die casting and silicone rubber parts manufacturing services in China. We are committed to providing our customers with high quality products, on-time delivery and competitive pricing.

We have a team of over 40 experienced engineers and technicians who are experts in their respective fields. We use the latest technology and equipment to ensure that our products meet the highest quality standards.

Our company policy is to respond quickly and treat each customer seriously, from small to large orders of all kinds. We are committed to growing with our customers by providing professional solutions from product development to mass production.

From prototype to mass production

- Design and manufacture plastic injection molds and die casting molds

- Production of custom plastic injection molded parts from small to large quantities

- Production of custom aluminum and zinc alloy die castings, OEM available

- Production of custom silicone rubber parts, Numerous material options

- Product assembly testing

- Technical support for plastic and metal parts

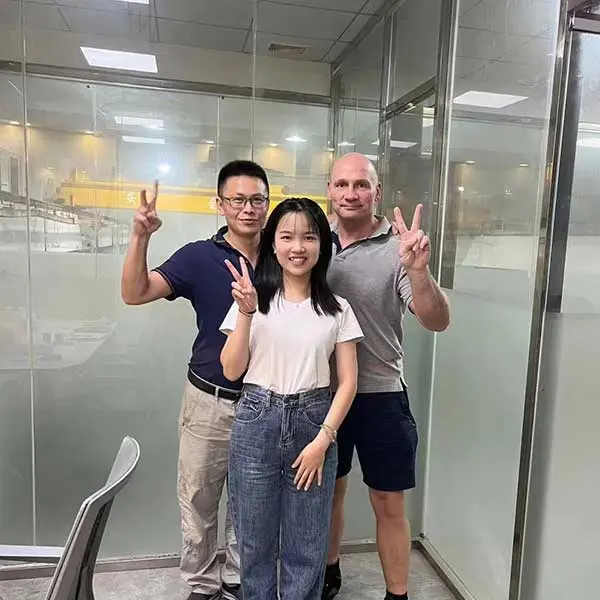

"Our service goal is simple: 100% customer satisfaction. That is my promise to you."

Jacob Deng / Co-Founder

Honest Business, Real Quality

I founded GPMFG in 2003 based on practical experience in mold making and plastic metal parts manufacturing, with a simple goal: to provide a manufacturing partner that respects your specifications and delivers exactly what we promise.

Our Service Goal: 100% Customer Satisfaction.

- Rules: We strictly follow standards and specs.

- Honest: We believe in transparent communication.

- Positive: We solve problems with a proactive attitude.

- Pleasure: We make cooperation easy and enjoyable.

Our History

- Mold Workshop established

- Specialized in injection and die-casting molds,.

- Exported to North America and European Union (EU),

- Die-casting workshop established

- Mainly for agricultural and consumer electronics products.

- Set up injection molding workshop

- For trial production of Export molds and Mass production

- Flexible order quantity

- CNC workshop established

- Metal parts Machining

- Secondary processing of plastic Die-casting parts

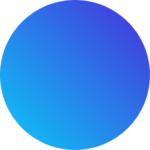

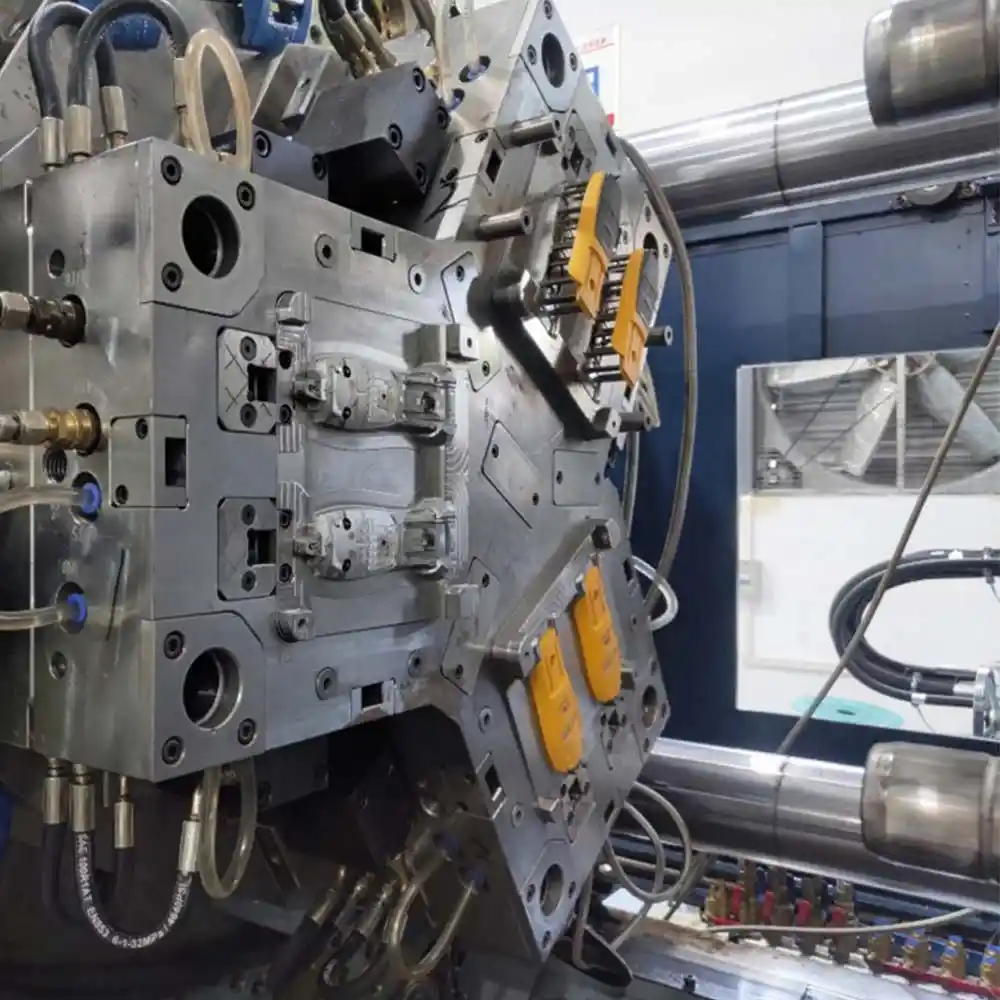

Highly-Equipped Manufacturing Workshops

With our development and manufacturing capabilities, you can customize products to your needs.

Mold Tooling Workshops

Injection Molding Workshops

Die Casting Workshops

Clients with us