CNC Machining Service

Our comprehensive CNC machining services encompass a diverse array of operations such as milling, turning, drilling, tapping, EDM, and wire EDM for a variety of materials. With our ISO 9001 certification, skilled expertise, and state-of-the-art CNC machines, we guarantee accurate and reliable manufacturing of your components on the initial attempt, without fail.

- CNC Fixture Development and Manufacturing

- CNC Machining Metal parts

- CNC Machining Plastic parts

- 3-5 Axis CNC Machining

- CNC Turning

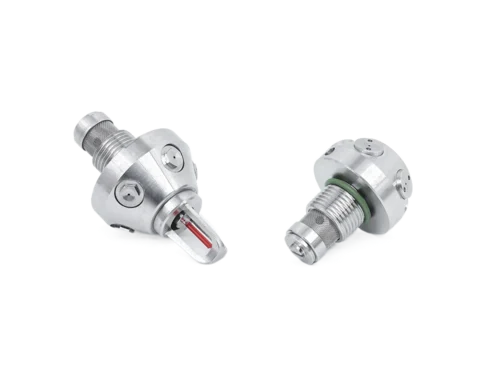

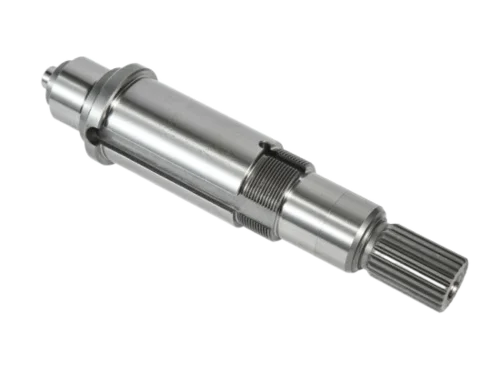

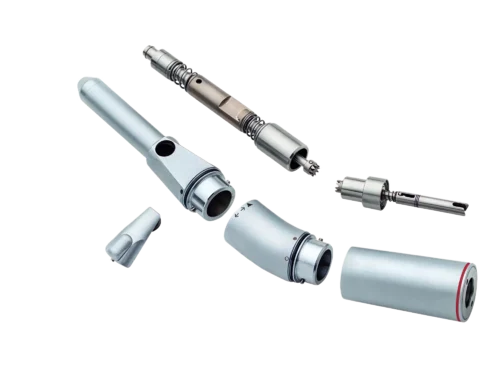

Precision Part Manufacturing for Various Industries

CNC machining services

More than 20 years of experience in CNC machined parts

40+ sets of cnc machining equipments

With various measure equipments

CNC Milling

- 3-axis, 4-axis, 5-axis CNC Milling

- CNC milling metal and plastic

- Tolerances of ±0.005mm

CNC Turning

- Facing, Taper Turning & Contour Turning

- Form Turning, Chamfering & Cutoff

- Threading, Boring, Drilling & Knurling

Precision Grinding

(+/-0.0001 in.)

- Centerless Grinding

- Cylindrical Grinding (OD & ID)

- Surface Grinding

EDM Machining

- Sink EDM

- Wire EDM

- Small Hole EDM

Deep Hole Drilling

- For Machine components

- For Mold components

- For Electronic products

Surface Finishing

- Various Finishing Options

- Anodizing, coating, polishing options.

- Improves aesthetics and corrosion resistance.

CNC Milling from 3 to 5 axis

3-Axis CNC Milling

- 3-axis CNC milling makes complex shapes.

- Best for planar profiles, holes in-line.

- T-slot and Dovetail cutters allow undercuts.

4-Axis CNC Milling

- 4-axis machining is cost-effective compared to 3-axis.

- A-axis reduces fixtures and errors.

- Tighter tolerances, no accuracy loss.

5-Axis CNC Milling

- 5-axis machining handles complex shapes, reduces setups.

- Efficiently machine 5 sides in one setup.

- 5-axis used for aerospace and medical parts.

Materials for custom CNC machining parts

We provide material certification and ROHS report for each batch of raw materials

aluminum

Aluminum alloys have thermal properties and excellent machinability, making them the material of choice for most manufacturing sectors in a wide range of industries and easy to machine.

Aluminum cnc machining materials:

al 6061, al 2024, al 5052, al 6063, al 7050, al 7075, al MIC-6.

CNC machining precision:

Our CNC machined parts with tolerances as small as +/- .0.01

Surface Finish Colors:

Black, natural, blue, green and different colors according to your requirements with high quality finish.

CNC machining process:

CNC aluminum milling, CNC aluminum turning, CNC aluminum drilling etc.

Copper/Brass

Brass is an alloy made of copper and zinc, characterized by high wear resistance, low coefficient of friction, low melting point, good ductility and high corrosion resistance.

High quality copper:

Brass 360, Brass 308, Copper 101, Copper 110, Copper 11000, Bronze, and more.

CNC Lathe Machining Accuracy:

Our CNC turning centers produce precision turned parts with tolerances as small as +/- .0.01

Competitive Pricing:

Providing advanced CNC brass turning technology currently available to large companies at a profitable price that any user can obtain.

Quality Assurance:

Advanced CNC lathes, competent designers and engineers, and experienced production workers ensure superior quality.

stainless steels

The best and fastest way to machine steel parts is CNC machining, especially CNC milling, which is especially popular in the medical, automotive, aerospace, healthcare and consumer electronics sectors

CNC machining materials:

Stainless Steel, Carbide, Carbon Steel

Surface Finishing Capabilities:

Brushed, polished, anodized, oxidized, sandblasted, laser engraved, electroplated, shot peened, electrophoresed, chromate, powder coated and painted.

CNC machining process:

CNC milling, CNC turning, CNC Drilling, CNC Tapping,EDM,Wire cut

CNC machining tolerances:

± .0002 inches, ± .005 mm.

Titanium

Titanium is a lustrous transition metal with a silvery color, very strong but lightweight, and non-magnetic. It has beneficial properties and characteristics such as good ductility, high melting point and low thermal conductivity, and is resistant to corrosion by seawater, chlorine and many more media.

Titanium CNC machining materials:

Titanium Grade 5 (Ti 6Al-4V), Grade 2, Grade 7, Grade 23 (Ti 6Al-4V Eli), etc.

Surface Finishing Capabilities:

Brushed, polished, anodized, oxidized, sandblasted, laser engraved, electroplated, shot peened, electrophoresed, chromate, powder coated and painted.

CNC machining process:

Drilling, thread milling, broaching, tapping, spline, reaming, cutting/cutting, profiling, facing, turning, threading, internal molding, grooving, knurling, countersinking, boring, countersinking, hobbing.

CNC machining tolerances.

± .0002 inches, ± .005 millimeters

Plastic

We are able to manufacture high quality CNC machined plastic parts from over 30 different materials, creating high performance precision machining of engineering plastics using processes such as 5-axis CNC machining methods.

CNC machining material:

POM, PEEK, HDPE, PET, Nylon, PTFE, PVC, PP, ABS, PC, PMMA

Surface Finishing Capabilities:

Deburring, chrome plating, anodizing, fumigation, grinding, sandblasting, painting, silk-screening, electroplating, etc.

CNC processing customization:

Provide customers with the best design and production solution for CNC milling plastic parts according to drawings and parameters.

CNC machining tolerances.

± .0002 inches, ± .005 millimeters

Metal Material List

| Material | Optional Machining Process | |||

| Material type | Material spec. | Die Casting | CNC Machining | Stamping |

| Aluminum | A2017,AL2024,AL6061,AL7075,2A12,AL5052,AL6082,AL6063,AL6060,AL7075-T73,MIC-6 | X | √ | √ |

| Stainless steel | 440C,410,420,465,17-4PH,303,304,316L,316F,303SE,15-5PH | X | √ | √ |

| Carbon Steel | 12L14,1025,1045,1018,CRS,C45,1013,S50,Mild steel,low carbon steel,Q235,Q345B,iron,grayiron,A36,1214,1215,1213 | X | √ | √ |

| Tool Steel | 4140,4130,NAK55,718H, PX9,A-265,4340,SKD11,SKD61,A2,M2,P20,S136,S7 | X | √ | X |

| Bronze | Phosphor bronze,Bearing Bronze,Oil Bronze,Alminum Bronze,Nickel aluminum bronzeTU1.TUP | X | √ | X |

| Copper | C11000.C12000,C12000,C26000,C51000,C36000,C18200,Tungsten copper,Berylliumcopper,WUCU | X | √ | √ |

| Brass | HPb63,HPb62,HPb61,HPb59,H59,H68,H80,H90,C360,C2600,C26000,C27000 | X | √ | √ |

Our surface finishing method

We offer a wide range of finishing services, including painting, texturing and polishing, and offer a wide selection of colors. In addition to superior quality, we are committed to the environment. We use environmentally friendly paints and coatings and recycle all waste materials.

Deburring

The standard finish for our parts, the “as machined” finish, has a surface roughness of 3.2 μm (126 μin), which removes sharp edges and deburs parts cleanly.

Materials

All materials

Color

n/a

Texture

Stain

Price

$

Bead Blasting

Bead blasting is the process of powerfully propelling, generally with high pressure, a stream of blast media against a surface to remove unwanted coating layers and surface impurities.

Materials

Aluminum, Steel, Stainless Steel, Brass, Copper

Color

n/a

Texture

Matte

Price

$

Anodizing

Anodizing is an electrolytic process that creates a protective layer of oxide on the surface of the die cast component. This improves its corrosion and wear resistance.

Materials

Aluminum

Color

Clear, black, grey, red, blue, gold

Texture

Smooth, matte finish

Price

$$

Electroplating

The process of electroplating deposits a thin layer of metal on the surface of a part. The most commonly used metals for electroplating are nickel, chromium, zinc and gold.

Materials

Aluminum, steel, stainless steel

Color

Gold, silver, nickel, copper, brass

Texture

Smooth, glossy finish

Price

$$$

Polishing

Ranging from Ra 0.8~Ra0.1, polishing processes use an abrasive material to rub the part’s surface to make the shine more less shiny, depending on your requirements.

Materials

All materials

Color

n/a

Texture

Smooth, glossy finish

Price

$$$$

Powder Coating

Using corona discharge, we make the powder coating adsorbed to the part, creating a more wear-resistant layer with a typical thickness ranging from 50 μm up to 150 μm.

Materials

All metal materials

Color

Custom

Texture

Glossy

Price

$$$

Brushing

Brushing can be used for aesthetic purposes, to improve the durability of the material, or to make the material more resistant to corrosion.

Materials

ABS, Aluminum, Brass, Stainless Steel, Steel

Color

n/a

Texture

Satin

Price

$$

Painting

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

Materials

Aluminum, Stainless Steel, Steel

Color

Custom

Texture

Gloss, semi-gloss, flat, metallic, textured

Price

$$$

Pad Printing

Pad printing is a process of transferring a 2D image onto a 3D object using a silicone pad. It is also a durable process that can withstand wear and tear.

Materials

All materials

Color

Custom

Texture

flat

Price

$$

Laser

Laser etching and engraving are two processes that use a laser to create permanent marks on a surface. Laser etching uses a laser to vaporize the surface of the material, while laser engraving uses a laser to remove material from the surface.

Materials

All materials

Color

Custom

Texture

flat

Price

$$$

Capability & process

Improve the efficiency of your CNC machining project by taking into account these important production considerations:

Process selection

| 3-Axis Milling | 5-Axis Milling | Turning |

|---|---|---|

| Effective for simple geometric designs | Adds 2 axes of movement to the workpiece for expanded design potential | Ideal for parts with simple geometries, or rounded and cylindrical parts |

| Useful for creating a wide variety of parts | Offers faster production times | Offers excellent precision and consistency |

| Offers excellent precision and consistency | Offers excellent precision and consistency |

General Capability Information

| 3-Axis Milling | 5-Axis Milling | Turning | |

|---|---|---|---|

| Max. Part size | 1800 x 1000 x 500 mm 70.9 x 39.4 x 19.7 in |

1000 x 900 x 600 mm 39.4 x 35.4 x 23.6 in |

Ø 350 x 600 mm Ø 13.8 x 23.6 in |

| Min. Part size | 12.7 x 12.7 x 12.7 mm 0.5 x 0.5 x 0.5 in |

12.7 x 12.7 x 12.7 mm 0.5 x 0.5 x 0.5 in |

6.4 x 6.4 x 6.4 mm 0.25 x 0.25 x 0.25 in |

| Min. Feature size | Ø 1 mm Ø 0.039 in |

Ø 1 mm Ø 0.039 in |

Ø 1 mm Ø 0.039 in |

| Standard tolerance | Metals +/-0.13 mm (+/-0.005 in) Plastics +/- 0.20 mm (+/- 0.008 in) |

Metals +/-0.13 mm (+/-0.005 in) Plastics +/- 0.20 mm (+/- 0.008 in) |

Metals +/-0.13 mm (+/-0.005 in) Plastics +/- 0.20 mm (+/- 0.008 in) |

| Lead time | As low as 8 days for less than 50 parts |

As low as 10 days for less than 50 parts |

As low as 8 days for less than 50 parts |

FAQs For CNC Machining

What is CNC machining service?

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses computer software to control machine tools. These tools can include lathes, mills, routers, and grinders, and they are programmed to perform precise movements and operations on materials such as metal, plastic, wood, and composites.

What are the advantages of CNC machining services?

- High Precision: Capable of achieving tolerances within thousandths of an inch.

- Automation: Reduces human error and ensures consistent quality.

- Design Flexibility: Easily accommodates complex geometries and rapid design changes.

- Increased Efficiency: Facilitates continuous operation, enhancing production speed.

- Versatility: Widely applicable in industries such as aerospace, automotive, and medical

What are the Disadvantages of CNC Machining?

- High initial cost: CNC machines can be expensive to purchase and install, making it difficult for small businesses or individuals to invest in this technology.

- Skilled operator requirements: CNC machines require skilled operators who are proficient in programming and operating the equipment. This can increase production costs, especially if there is a lack of skilled labor.

- Limited flexibility: While CNC machines are great for producing large numbers of identical parts, they may not be the best choice for producing one-off or custom parts due to the high set-up time and cost.

What kind of CNC machining services do you offer?

CNC services: milling, turning, EDM, prototyping, and material support for custom parts in 7 days. Fast, quality-driven, and tailored to your specs.

What is your CNC machining capability?

Our CNC center boasts expert teams and advanced machines, delivering precision machining for diverse projects. Operating round-the-clock, we ensure quick turnarounds and can manufacture over 100,000 parts monthly.

What is the typical cost of a CNC machined part?

We offer tailored quotes for CNC machining, factoring in process differences that affect part pricing. 5-axis milling is generally more expensive than 3-axis, with potential costs doubling. For cost savings, we suggest larger production runs to minimize setup expenses per part.

What are the maximum size ranges of your machine travel?

Maximum Dimensions (3-axis milling): 1800 x 1000 x 500 mm / 70.9 x 39.4 x 19.7 in

Maximum Dimensions (5-axis milling): 1000 x 900 x 600 mm /39.4 x 35.4 x 23.6 in, Worktable Diameter Φ400 mm.

How do you ensure the quality of my parts?

As an ISO-9001-certified factory, we ensure top-quality standards for international orders. Our QC/QA team uses specialized equipment for detailed inspections, providing 2D, CMM, and 3D reports. We follow MIL-STD-105E for thorough quality checks with zero defects. All parts come with inspection reports to confirm they meet your specs.