Mold Manufacturing

We create dependable molds for high-quality customized parts ensuring precision, fast production, competitive pricing, and reliable outputs.

- Mold follow,Mold Design, Mold Manufacturing

- Prototype Molds,low life Molds up to 1 Million-shots Molds

- Single Cavity Molds, Multi Cavity Molds,Family Molds

- Plastic Injection Molds, Die Casting Molds

Customized Tooling/Molds For Your Industries

Our services cover a wide range of fields including medical, electronics and automotive, creating top-quality injection molds for global plastics manufacturers. In addition to mold creation and design, our in-house manufacturing includes a full suite of services including OEM, injection molding,die casting & CNC

Plastic Injection Molds Manufacturing

- Precision design for high-volume production and dimensional consistency

- Ability to incorporate complex shapes and features with tight tolerances

- Injection molding tool design for manufacturability to minimize material waste and maximize efficiency

- Robust tool construction to withstand high pressure and temperature during the molding process

- Incorporation of actions, lifters, and unscrewing mechanisms to facilitate part ejection and minimize parting line flash

Die Casting Molds Manufacturing

- High thermal conductivity for efficient heat dissipation during casting

- Customization of gating and runner systems to optimize flow and minimize defects

- Incorporation of cooling channels to ensure consistent quality and prevent warpage or distortion

- Precision machining and tooling to ensure dimensional accuracy and repeatability

- Documented maintenance, revision, and repair services to ensure longevity and minimize downtime.

Types of Plastic Injection Molds

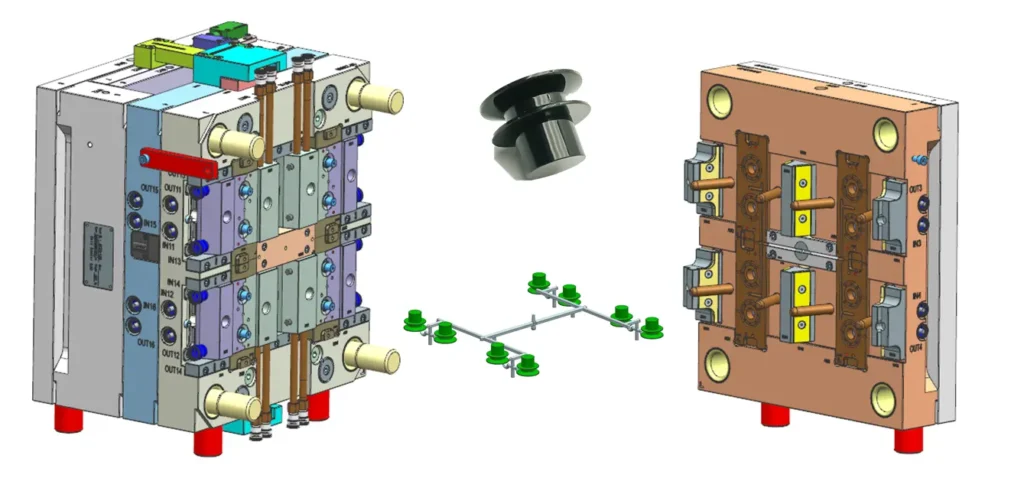

Perfume bottle cover Tooling/Mold

Industry: Cosmetic product packing

Mold Base steel:P20

Mold Cavity Steel :1.2083(HRC48-52)

Cavity: 8 Cavities

Mold Life:1,000,000 shot

Surface Finish:Mirror Polish

Mold Feature: Double ejection

Food Container Tooling/Mold

Industry: Foods packing

Mold Base steel:P20

Mold Cavity Steel :P20,BE-CU

Cavity: 1*1

Mold Life:1,000,000 shot

Surface Finish: Standard Polish

Mold Feature: Fast cooling for molding

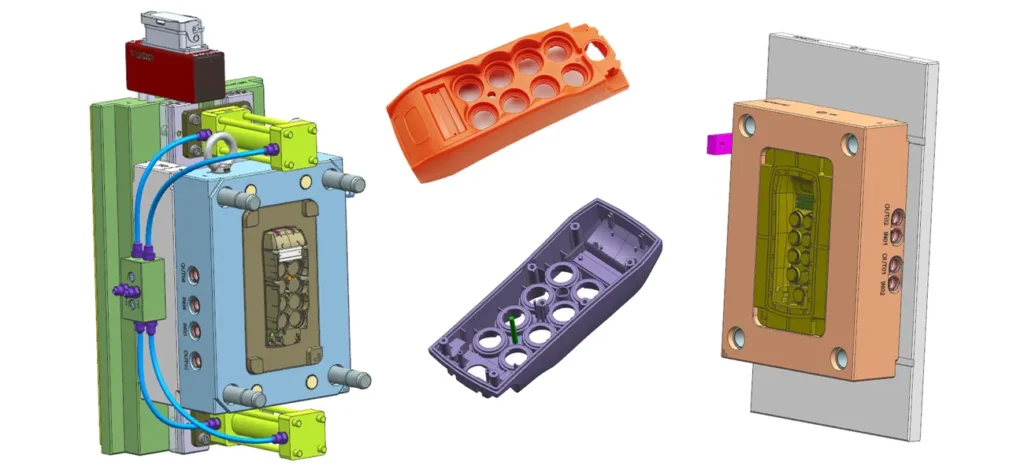

Controler Housing Tooling/Mold

Industry: Electronic & Electrical

Mold Base steel: 1050

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: YUDO hot nozzle

Electrical housing Tooling/Mold

Industry: Electronic & Electrical

Mold Base steel:S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: Colored Nylong

Medical Tooling/Mold

Industry: Medical device

Mold Base steel:S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1+1

Mold Life:500,000 shot

Surface Finish: VDI-27

Mold Feature: Family mold

Medical Tooling/Mold

Industry: Medical device

Mold Base steel:P20

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*4

Mold Life:1,000,000 shot

Surface Finish: Mirror Polish

Mold Feature: HASCO hot nozzle

T-branch pipe Tooling/Mold

Industry: Household

Mold Base steel:P20

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Unscrewing movement

U pipe Tooling/Mold

Industry: Household

Mold Base steel:P20

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Arc slider

Oil pipe Tooling/Mold

Industry: Automobile

Mold Base steel: S50C

Mold Cavity Steel :1.2344(HRC48-52)

Cavity: 1*2

Mold Life:500,000 shot

Surface Finish: MT-11010

Mold Feature: Multiple Sliders

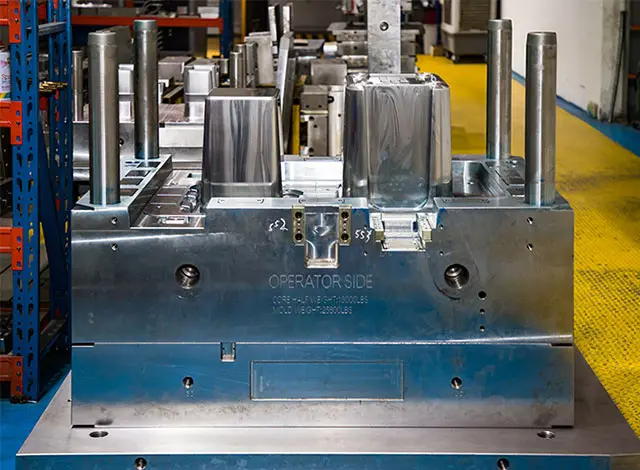

Automobile Tooling/Mold

Industry: Automobile

Mold Base steel:P20

Mold Cavity Steel :1.2343(HRC48-52)

Cavity: 1*1

Mold Life:500,000 shot

Surface Finish: Mirror Polish

Mold Feature: Synventive hot nozzle

Excellent mold manufacturing capability

Much Cheaper Than Your Local Supplier

- 3-Axis, 4-Axis, 5-Axis CNC Milling

- CNC Milling Metal And Plastic

- Tolerances Of ±0.005mm

ISO 2768 CNC Machining Standard

- Facing, Taper Turning & Contour Turning

- Form Turning, Chamfering & Cutoff

- Threading, Boring, Drilling & Knurling

Approved By Over 52 Mold Makers

- Sink EDM

- Wire EDM

- Small Hole EDM

Precision Tolerances Of ±0.003 Mm

(+/-0.0001 In.)

- Centerless Grinding

- Cylindrical Grinding (OD & ID)

- Surface Grinding

Processing Flow To Get Stable Running Tooling/Molds

The person responsible for the whole steps of tool/mold manufacturing and progress tracking.

Process flow

Quotation,each order Qty. provided

Technic Documents

Product 3D drawing

Product 2D drawing with Tol.

Person in Charge

Customer

Schedule

Within 48H

Process flow

New project launches

Technic Documents

Formal product 3D drawing

Formal product 2D drawing with Tol.

Person in Charge

Customer

Schedule

When ordering

Process flow

Tooling/Mold design

Technic Documents

Mold Flow analysis if need

DFM report

3D Tooling/Mold drawing (x_t)

Person in Charge

Designer

Schedule

within 6 days

Process flow

Mold Drawing approved

Technic Documents

/

Person in Charge

Customer

Schedule

/

Process flow

Report Progress every Monday

Technic Documents

Weekly Tooling/Mold Progress Report

Person in Charge

Project Engineer

Schedule

Every Monday

Process flow

Order Tooling/Mold steel

Technic Documents

Certificate of steel,Heat Treatment Report

Person in Charge

Workshop

Schedule

/

Process flow

Mold Manufacturing

Technic Documents

/

Person in Charge

Workshop

Schedule

/

Process flow

Mold trialing and Making T1 samples

Technic Documents

/

Person in Charge

Workshop

Schedule

/

Process flow

Inspect and Send T1 samples to customer

Technic Documents

Injection parameter report

Mold Test video

Product FAI report Injection Filling balance report

Mold fitting report

Person in Charge

Project Engineer

Schedule

Day of sending sample

Process flow

Mold improvement and modification

Technic Documents

/

Person in Charge

Workshop

Schedule

Within 7 days

Process flow

Resend samples

Technic Documents

Same as T1 samples

Person in Charge

Project Engineer

Schedule

/

Process flow

Mold approved

Technic Documents

/

Person in Charge

Customer

Schedule

/

Process flow

Mold Full inspection

Technic Documents

Mould acceptance inspection report with pictures

Person in Charge

Project Engineer

Schedule

Within 3 days after Mold approved

Process flow

Mold trial production,500 shots

Technic Documents

Mold trial production pictures

Person in Charge

Workshop

Schedule

Within 3 days after Mold approved

Process flow

Rustproof packaging

Technic Documents

Rustproof packaging pictures

Person in Charge

Workshop

Schedule

Within 3 days after Mold approved

Process flow

Rustproof packaging

Technic Documents

Components & documents List for shipping

2D Mold drawing

3D Mold drawing

EDM drawing & Electrode

Certificate of steel material

Certificate of mold base

Heat Treatment Report

Mould acceptance inspection report with pictures

Person in Charge

Project Engineer

Schedule

Report filed and printed with the mold

Mold making process

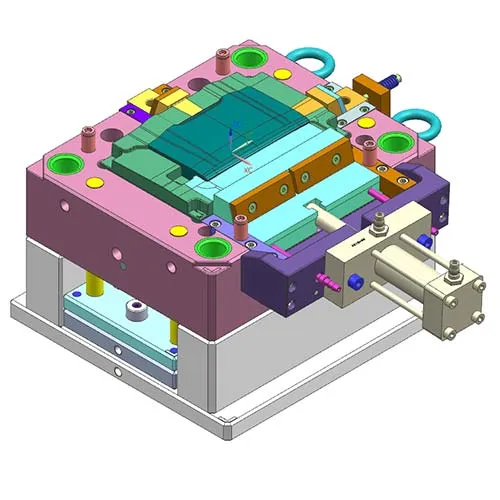

DFM and mold design

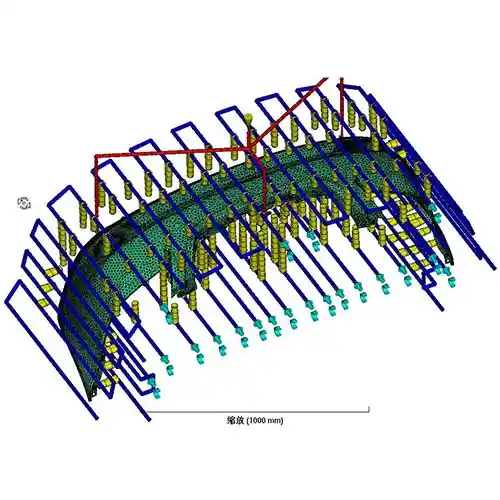

Injection mold design begins with a DFM program (Design for Manufacturability), presenting crucial mold design information such as dimensions, cavity layout, runner system, pouring method, parting line, ejection method, mechanical design, accessories, steel selection, and cooling design. After customer approval, detailed 3D design and NC programming are carried out, taking 3-5 days for a complete design. Complex projects may require mold flow analysis or frequent part design updates, prolonging the process.

Planning, Mold base, steel and accessories preparation

Upon mold design approval, our project manager will create a detailed project schedule covering the entire process until T1 sampling. Your assigned project manager at GPMFG will provide weekly updates. Mold base and steel can be ordered immediately after design approval, while accessories like the hot runner system may have longer lead times. It is crucial to closely monitor and track these procedures to avoid delays in subsequent steps.

Rough machine

In order to obtain the desired rough shape or cavity/core, the steel must undergo initial sizing, milling, drilling, and lathe processes. Typically, a steel thickness of 0.15-0.3 mm is retained for precision machining in subsequent stages.

Heat treatment

Heat treatment is a critical process following rough machining, as it serves two key purposes: achieving specific hardness levels and attaining internal balance. For instance, materials like 1.2343 and 1.2344 typically require hardening to a range of HRC48-52.

CNC precision machining

CNC precision machining involves meticulous attention to detail. Unlike rough machining, the CNC process operates at a slower pace with reduced cutting amounts. This method produces finely machined mold inserts with a smooth, glossy finish and accurate dimensions, achieving a maximum tolerance of 0.01-0.005mm.

Wire cut and EDM

Wire cutting is specifically used for various through holes (ejector pin holes, lifters, inserts), while EDM is suitable for features that cannot be machined by CNC due to depth or narrowness. To minimize the time and cost associated with EDM, experienced designers optimize mold design by dividing the main insert into multiple sub-inserts. This allows for direct CNC machining of the inserts, reducing the reliance on wire cutting and EDM processes.

Finish and fitting

Once all the components have been completed and prepared, our engineers gather them together and expertly assemble them according to the design drawing. This crucial task heavily relies on their vast experience and exceptional skills. In some instances, certain parts may require polishing or even reworking in order to achieve a perfect fit. Moreover, the core or cavity often have specific surface finish requirements, such as texture, polish, or engraving, which are meticulously addressed.

Mold trial

When everything is prepared, we will put the mold on the injection molding machine for a test. Make sure you clearly state your requirements, how many plastic parts you need as samples, instruct the moldmaker to use the correct resin, and that injection parameters and measurement reports should be provided with the molded plastic parts.

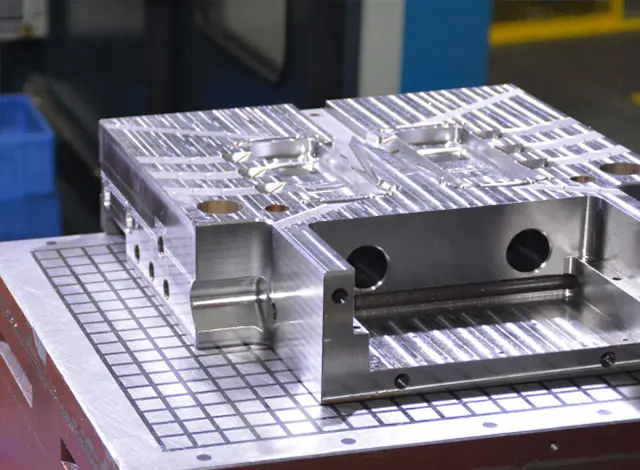

Mold Tooling Workshops

CNC workshop

EDM workshop

Wire-cut workshop

Grinding workshop

Quality Department

Assembly Department

Selection of materials for mold making

| Component Name | Steel&Hardness | Equivalent Steel | Mold Life(Shot) | Price Index | Applications |

| Mold base | 1050 | 1730 | 500,000 | 1 | Plastic injection mold |

| LKM P20 | 2311 | 1,000,000 | 1.35 | Plastic injection mold | |

| LKM P20 | 2311 | 500,000 | 1.35 | Die-casting mold | |

| H13 (HRC 44-46) | 2344(HRC44-46)/SKD61 | 1,000,000 | 2.1 | Plastic injection mold | |

| Mold Cavity/Core | P20 | 2311/718H/2378 | 200,000 | 1 | Plastic injection mold |

| P20H(HB330-370) | 2738H/718HH/NAK80 | 300,000 | 1.3 | Plastic injection mold | |

| S136H(HB290-330) | 2083H/420H/2316H | 500,000 | 2.2 | Plastic injection mold | |

| S-136 (HRC 48-52) | 2083/420ESR/2316 | 1,000,000 | 3.2 | Plastic injection mold | |

| H13 (HRC 48-52) | 2344/2343/SKD61 | 1,000,000 | 3.2 | Plastic injection mold | |

| H13 (HRC 48-52) | 2344/2343/SKD61 | 80-150K | 3.2 | Die-casting mold | |

| 8407 (HRC 50-52) | 8418 | 150-300K | 5 | Die-casting mold |

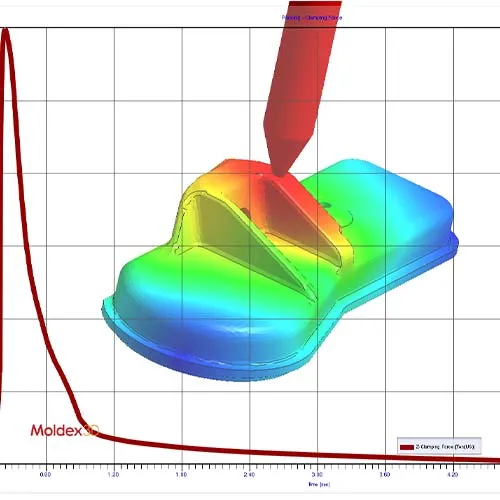

Molding analysis ensures successful mold design

GPMFG’s engineers employ finite element analysis software to simulate the behavior of molten polymers during complex injection molding processes. By analyzing the collected data, we can predict and identify potential molding issues, providing guidance to optimize designs.

1. The analysis of flow:

Predicting filling delays, hits, and balance

Analyzing mating lines, pack wind positions, and glue feeding

Determining injection pressure and closing force requirements

2. Flow channel balance analysis:

Balancing flow channel systems in multi-cavity mold cavities or families Recommending flow channel sizes and quantities for achieving flow balance

3. Gate position analysis:

Analyzing the best gate location for optimal mold flow

Automatically analyzing the position of additional gates

4. Cooling analysis:

Assessing the mold's cooling water layout

Identifying areas that require stronger cooling

Predicting molding cycle and evaluating product thickness

5. Warpage analysis:

Predicting product deformation and shrinkage values in X and Y directions

Adjusting water inlet/pressure holding parameters to reduce mold deformation

6. Shrinkage analysis:

Analyzing molding shrinkage with put number and volume

Assessing the presence of shrinkage marks

7. Gas-assisted analysis:

Predicting gas-assisted molding shrinkage and deformation

Evaluating gas penetration distance, effect, and optimal location

8. Core transfer analysis:

Predicting mold core shift trend and correcting mold design

Reducing the weak impact strength of core during filling

9. Stress analysis:

Predicting residual stress distribution and size in molded products

10. Fiber orientation analysis:

Controlling the fiber orientation of plastic, injection molded parts

Simulating percentage simulations according to different fibers

Improving material properties such as bending and tensile strength

11. Overmolding analysis:

Analyzing flow, warpage, and bonding in two-color molding

12. Microchip encapsulation analysis:

Predicting chip encapsulation, flow, and curing conditions in mold cavity

Assessing the effect of flow on gold wires and pins

13. Bottom fill analysis:

Optimizing thermoset molding conditions and fill dispensing model simulation

Predicting various forms and injection pressure/clamping force requirements

14. Birefringence prediction:

Adjusting gate position, process conditions, or modifying product structure to achieve low residual stress

Predicting the occurrence and severity of asymmetric birefringence in optical parts.

FAQs for Mold Manufacturing

What information should be provided to obtain the quotation?

Formal product 3D drawing

Formal product 2D drawing with Tolerance

Parts mateirla

Molds Cavity number if exporting molds

Injection point type if exporting molds

Molds cavity steel if exporting molds

Molds frame steel if exporting molds

Molds life if exporting molds,shot

What’s the process for injection mold making?

In order to meet the requirements of customers, GP MFG designs molds and manufacturing processes through analysis and strict molding process, to ensure the perfect increase in the production of molds.

Step 1: Provide DFM report and mold flow analysis report for customer confirmation

Step 2: Provide design mold drawings for customer confirmation

Step 3: Provide reconfirmation of the drawing after modification of the mold design

Step 4: After the drawing is confirmed Ok, start to arrange the mold manufacturing

Step 5: Provide weekly tooling progress report

Step 6: Send out T1 sample until the mold is confirmed Ok

Can you customize the mold according to my sample?

Yes.

- If accurate product drawing is available,attach 2D product drawing with tolerance and 3D product drawing.

- If you have accurate sample, if there are no drawings or only sketches, please provide the final sample,we will arrange to make a DFM report to send to you for confirmation, and then design the mold.

How much does a mold cost?

The cost of the mold is affected by the size and material of the product,the complexity of the structure and the quantity of production,and the surface requirements, and so on.Because of the great difference,the price of the mold can not be estimated.If you want to know the cost of mold precision,please send email to us.

How long does it take to make a mold?

It depends on the complexity of the product structure,the specific delivery time will be indicated on the quotation sheet.The following delivery dates are for reference:

20-30 days for molds less than 1 ton

30-45 days for molds from 1 ton to 3 tons

45-60 days for molds from 3 ton to 5tons

How long is the mold life? How to protect?

In the mold industry,the life grade of the mold is divided into:100 thousand times,300 thousand times,500 thousand times and 1 million times.The die life is related to the die steel,which is selected according to the plastic material,the surface treatment of the parts and the potential production quantity.

Mold exported to customers in your country or region,in the correct use of die mold and regular maintenance,the service life of the actual can completely meet the design service life,a failure if the life of the mold in a reasonable period,our project engineer will evaluate the replacement parts or mold repair solution,will arrange manufacture and send again.