OEM Services -

Your Partner for Contract Manufacturer

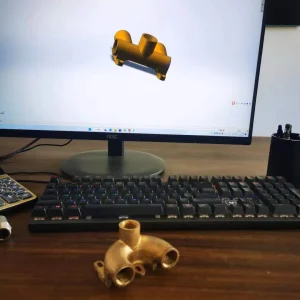

One-stop OEM manufacturer for design, prototyping, manufacturing, assembly and shipping

- 30% less than local prices

- 100+ OEM product experience

- 40% reduction in delivery time

One-Stop Plastic Metal Components & Assembly Solution

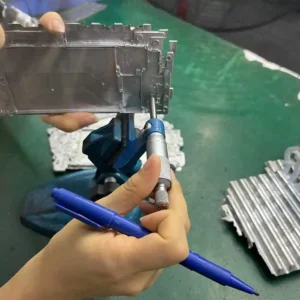

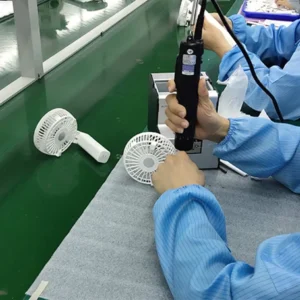

As a manufacturer of plastic and metal parts, we also offer a one-stop OEM service including product assembly and performance testing, to meet the needs of our brand clients. This covers every stage of production, from design to delivery.

Material Selection

Confirm the surface finish

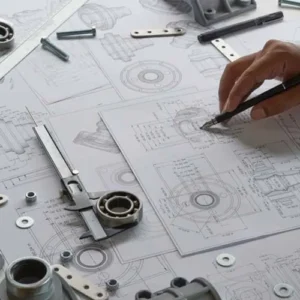

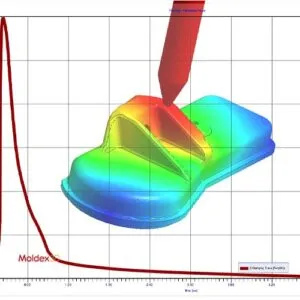

DFM analysis & improvement

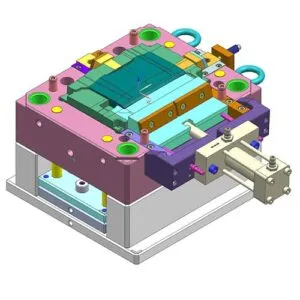

Mold Design

Mold Making

Making Smaples

Product test and approved

Production

Product Assembly

Packaging and delivery

OEM Cases

Case: Safety Helmet

About the Product

Service scope: Plastic tool manufacturing and plastic injection molding

Tool life: 500,000 injections

Tool Material: P20 steel

Product Material: High-impact ABS

Post-processing: Pad printing

About the customer

The customer is a renowned construction equipment manufacturer based in Germany. They specialize in producing safety equipment and have a strong reputation for delivering high-quality products. The customer has chosen our company, GPMFG, as their manufacturing partner due to our expertise in plastic tooling and injection molding.

About the request

The helmet shell needs to be made of high-impact ABS, ensuring durability and resistance to impact forces.

The customer wants their company logo and safety certifications to be prominently displayed on the helmets. Therefore, pad printing is required to apply these markings accurately.

How to serve

For this project, we will design and manufacture two injection molding tools: one for the helmet shell and another for the internal components. The helmet shell will be made from high-impact ABS, which offers excellent impact resistance and toughness. The tooling material chosen for this project is P20 steel, known for its durability and suitability for high-volume production. Additionally, we will perform plastic injection molding to produce the helmet shells and internal components. Finally, we will utilize pad printing to apply the customer’s logo and safety certifications onto the helmets, ensuring a professional and branded appearance.

FAQs For OEM

What is OEM service?

OEM service refers to the process where a company manufactures products or components that are specifically designed and branded for another company’s end products. It involves creating items like plastic parts or electronic components to meet the client’s exact specifications, ensuring they integrate seamlessly into the client’s products.

What are the advantages of OEM?

- Quality control: OEM parts are made according to specific standards and quality requirements, which ensures their consistency and reliability.

- Fit and compatibility: OEM parts are designed to fit and function perfectly in the products they are intended for.

- Warranty and support: The use of OEM parts often comes with manufacturer warranties and support.

- Cost savings: OEM parts are usually priced competitively, especially when purchased in large quantities.

What are the risks of OEM?

Quality issues: OEM plastic parts may not meet the quality standards required for their intended use. This can lead to product failures or malfunctions.

Material selection: The choice of plastic material for OEM parts may not be appropriate for the specific application, leading to problems such as brittleness, poor strength, or poor resistance to temperature or chemical exposure.

Design flaws: OEM plastic parts may have design flaws that could lead to unexpected failures or malfunctions. These flaws may not be apparent until the part is put into use.

Supply chain disruptions: OEM plastic parts may be sourced from a single supplier, making the supply chain vulnerable to disruptions such as natural disasters or factory shutdowns.

Does OEM cost more?

OEM products match the original equipment for guaranteed compatibility and reliability, potentially saving on future repair costs. They are often made with superior materials for durability and come with warranties and support. Although initially pricier, OEM parts can be more cost-effective in the long run due to their longevity and support. We offer top-tier OEM injection molding at competitive prices, prioritizing value over just initial cost.

How to choose OEM manufacturer?

Choosing the right OEM manufacturer is crucial for your project’s success. GPMFG stands out in injection molding for its commitment to quality, precision, and reliability.

At GPMFG, we prioritize high-quality injection molded products that meet rigorous industry standards. Our skilled engineers use advanced technology to ensure every product meets your specifications.

Precision is key in injection molding, and we utilize cutting-edge software and equipment to maintain tight tolerances and consistency.

Reliability is essential; GPMFG consistently delivers on time and within budget, even for complex projects.

We also offer a full range of services, including design, engineering, tooling, and production, ensuring comprehensive support for your project.