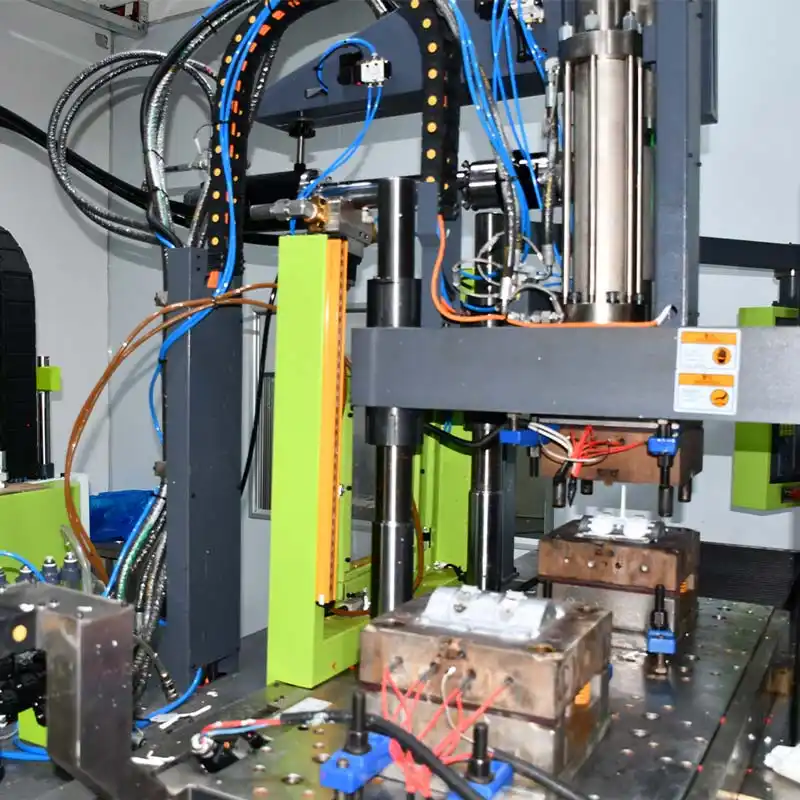

Silicone Rubber molding

GPMFG provide efficient, reliable, and high-quality silicone rubber molding solutions for your products.From Tooling/Molds design,manufacturing to molding productiong.

- Products/Parts Analysis & Optimizing

- Tooling/Molds Development & Manufacturing

- Compression Molding of Solid Silicone Rubber

- Injection Molding of liquid Silicone Rubber

- Insert Molding of Silicone Rubber

- Overmolding of Silicone Rubber

- Diverse Post processes available

Silicone Rubber molding Supplier - reducing trial and error costs

GPMFG has over 10 years of experience manufacturing custom silicone rubber parts and produces 7,000,000+ silicone rubber parts per year for Europe and the United States. We offer high quality medical grade silicone materials with hardness ranging from 5A to 85A.

- Minimum order of 1 - 100K+ parts

- Get silicone parts within 5 days

- Get a quick quote in less than 12 hours

- Complex elastomer parts & high level of detail

Custom Molded Silicone & Rubber Parts - Injection & Compression Molding

Rapid silicone rubber prototyping. High- or low-volume compression & injection molding part production.

Silicone rubber compression molding

Silicone rubber compression molding uses uncured rubber that has been preformed into a controlled shape, such as a disc. The mold surrounds the part and compresses it between two plates under high pressure. The high temperature and pressure vulcanize the rubber to cure the part. Pins automatically eject the part from the mold, speeding up production. Silicone rubber compression molding offers excellent chemical resistance, durability and flexibility, and also allows the use of multiple colors, textures and durometers in a single product, providing designers and engineers with greater product design flexibility.

Silicone rubber Injection molding

Silicone rubber injection molding is to inject liquid silicone rubber into the mold cavity under high pressure and high temperature. The silicone rubber then cures and cures to form the finished product. Liquid silicone rubber can flow into tight spaces and accurately reproduce fine features. In addition, silicone rubber has excellent heat resistance, electrical insulation, and biocompatibility.

Silicone rubber compression molding process & characteristics

Silicone rubber compression molding is a manufacturing process used to create silicone rubber products, such as seals, gaskets, and o-rings. This method is known for producing high-quality, high-precision parts with consistent dimensions and excellent surface finish. It also allows for customization of the rubber’s properties, such as hardness and color.

Compression Molding

The equipment and tools required for the compression molding are much simpler, which means less capital investment. The form of molding is suitable for mass and rapid production of products with simple design, product tolerance of ±0.05mm, and low budget.

Silicone compression molding is a manufacturing process used to produce high-quality silicone rubber products. Here are the basic steps involved in the process:

How it Word

Preparing the silicone material: The silicone is typically in the form of a compound or a mixture of silicone polymer, fillers, and other additives. The compound is typically mixed in a high-speed mixer or a two-roll mill until it is uniform.

Preparing the mold: The next step is to prepare the mold. The mold is typically made of steel or aluminum and is designed to the shape of the final product. The mold is usually made in two halves, which are held together using a clamp.

Loading the mold: Once the mold is prepared, the silicone material is loaded into the mold. The mold is filled with the silicone compound using a hydraulic press or an injection molding machine. The amount of material loaded into the mold is critical to ensure the final product meets the desired specifications.

Compression and curing: Once the mold is filled, the two halves of the mold are clamped together, and the silicone material is compressed to the desired shape. The mold is then heated to a specific temperature, typically between 150°C to 200°C, to cure the silicone material. The curing time varies depending on the thickness of the final product and the type of silicone used.

Demolding: Once the silicone material is cured, the mold is opened, and the final product is removed. The excess material is trimmed, and the final product is inspected to ensure it meets the desired specifications.

Advantages

- Low mold cost

- Low price of raw materials

- Low price of products

- High precision and tight tolerances

- Creating porous products

Disadvantages

- Limited material selection

- Long cycle times

- Limited automation

- Limited part size

Single Molding

Only a single variety of silicone is utilized in the production of silicone items in this molding process.

Overmold Products

The seamless integration of silicone rubber with various materials, including metal, plastic, and others, into a single part or product is achieved through a molding process.

Silicone rubber Injection molding process & characteristics

Silicone rubber injection molding offers several advantages over other molding processes, such as high precision, low waste, and the ability to mold complex geometries. Silicone rubber is known for its excellent thermal stability, chemical resistance, and biocompatibility, making it ideal for use in a variety of industries, including medical, automotive, and electronics.

Liquid Silicone Molding

The LSR molding is suitable for the production of silicone components with complex shapes, high precision, micro overmolding, and strict hygienic requirements. The tolerance of the product can meet ± 0.02mm, have no vulcanization residue

How it Word

Silicone rubber injection molding is a process that involves material preparation, mold creation and preparation, injection, vulcanization, de-molding, inspection, and packaging. It is a versatile and efficient manufacturing method used in a variety of industries to create a range of products.

Mold Creation:

A metal mold is created to the desired shape of the final product.

Mold Preparation:

The mold is cleaned and coated with a release agent to prevent the silicone from sticking to it.

Injection Process:

The silicone compound is injected into the mold through a sprue using a hydraulic press.

Vulcanization:

The mold is heated to cure the silicone and create the final product.

De-molding:

The product is removed from the mold and excess material is trimmed off.

Inspection:

The product is inspected for any defects or imperfections.

Packaging:

The product is packaged and prepared for shipping.

Advantages

- High precision

- Consistent quality

- Wide range of hardness

- Complex geometries part

- Tight tolerances

Disadvantages

- High initial cost

- Limited Overmolding Options

- Potential Flashing

Single-Shot Molding

Only a single variety of silicone is utilized in the production of silicone items in this molding process.

Overmold Products

The seamless integration of silicone rubber with various materials, including metal, plastic, and others, into a single part or product is achieved through a molding process.

Our exquisite Silicone & Rubber Molding capabilities

Our Silicone & Rubber Molding capabilities are exceptional and unmatched in the industry. Our precision molding techniques and attention to detail result in durable, long-lasting products.

| Material | Solid silicone rubber |

|---|---|

| Process | Compression Molding |

| Environmental safety | Environmental Class |

| Application | Electronics and Electrical Industry, etc |

| Product Tolerance | Tightest ±0.05 mm, Recommend ±0.1 mm |

| Product Thickness | Average 3.0 mm, Min. 0.4 mm, Max. 15-20 mm and 30mm for ball |

| Assembly Gap | 0.2-0.5 mm |

| Shrinkage | 1.03 |

| Cutting Method | Tear Lines Made In Mold Pull Off Flash Material |

| Temperature Range | Operating Temperature: -30° C to +180° C Storage Temperature: -42° C to 250° C |

| Material | Liquid silicone rubber |

|---|---|

| Process | Injection Molding |

| Environmental safety | Food Class |

| Application | Food and Medical industries |

| Product Tolerance | Tightest ±0.05 mm Recommend ±0.1 mm |

| Product Thickness | Average 3.0 mm, Min. 0.4 mm, Max. 15-20 mm and 30mm for ball |

| Cutting Method | Tear Lines Made In Mold Pull Off Flash Material |

| Temperature Range | Operating Temperature: -30° C to +180° C Storage Temperature: -42° C to 250° C |

what makes us different

Silicone Rubber Molding From Concept to Creation

Design & Prototype Service

With a focus on delivering exceptional value to our clients, we leverage our extensive experience and cutting-edge technology to provide comprehensive injection molding solutions that offer exceptional accuracy and repeatability, while remaining affordable and accessible to businesses of all sizes.

Mold tooling Design and make

We prioritize a holistic approach when creating Silicone Rubber molds, which involves close collaboration with our customers to ensure their unique specifications and requirements are met. Our plastic medical consumable supplies are known for their exceptional consistency, precision, and overall quality.

Rigorous Material Selection

Our innovative separation technology helps to increase your product yield by eliminating impurities and improving the efficiency of the separation process. The separation columns and resins utilized in our process minimize the number of purification steps, resulting in more efficient bioprocessing applications.

CNC machining

In our precision engineering process, we employ advanced laser cutting technology to produce intricate metal parts with unparalleled accuracy and speed. This automated manufacturing technology allows us to create complex designs that are crucial to many industries.

Molding Method in Clean Room

At GPMFG, we specialize in silicone molding and employ clean room techniques to produce medical-grade silicone components, mitigating the risk of impurities from minute particles such as dust. Our stringent in-process controls ensure that we consistently maintain a zero-defect level of quality in our products.

Secondary Operation

Our extensive range of secondary operations and assembly lines elevates the silicone rubber molding process to a whole new level. We provide meticulously labeled and fully assembled silicone and rubber molded parts and subassemblies, which lead to enhanced quality, efficiency, and cost-effectiveness.

Selection of materials for Silicone Rubber Molding

Choosing the right materials for silicone rubber molding is crucial to ensure high-quality, durable products. We have a wide range of options to meet your specific needs and guarantee the best results.

Silicone Rubber

Silicone rubber is a synthetic rubber that can be used in various industries, including automotive, medical, and consumer products. It is a popular material for molding due to its excellent temperature resistance and flexibility.

Advantages

High temperature resistance, good chemical resistance, excellent electrical insulation, good weatherability, resilience and flexibility, odorless and tasteless, non-toxic and biocompatible.

Disadvantages

Poor tear strength, not suitable for some oils and fuels, high compression set, high cost compared to other rubber materials.

Fluorinated Silicone Rubber

Fluorinated silicone rubber is a specialized type of silicone rubber that has superior chemical resistance and high-temperature resistance. It is often used in demanding applications such as chemical processing and aerospace.

Advantages

Excellent high-temperature resistance, superior chemical resistance, good electrical insulation, good compression set, low permeability to gases and liquids, good flame resistance.

Disadvantages

Expensive compared to other rubber materials, low tear strength and tensile strength, limited availability of grades and colors.

Nitrile Rubber

Nitrile rubber, also known as NBR, is a synthetic rubber that is resistant to oils and fuels. It is commonly used in the automotive industry for sealing and gasket applications.

Advantages

Good resistance to oils and fuels, high tensile strength, good abrasion resistance, good weatherability, good compression set.

Disadvantages

Poor resistance to ozone and sunlight, limited flexibility.

Neoprene Rubber

Neoprene rubber is a synthetic rubber that is resistant to oils, chemicals, and weather. It is often used in outdoor applications where resistance to weather and abrasion is important.

Advantages

Good resistance to oils, chemicals, and weather, good abrasion resistance, good resilience and flexibility, good flame resistance, good electrical insulation.

Disadvantages

Limited temperature range, poor resistance to ozone and sunlight, poor resistance to some solvents.

Natural Rubber

Natural rubber is a plant-based material that is commonly used in the production of tires and other automotive applications. It has good tear strength and flexibility.

Advantages

Good tear strength, good resilience and flexibility, good abrasion resistance, good electrical insulation, good low-temperature performance.

Disadvantages

Poor resistance to oils, fuels, and some chemicals, limited temperature range, poor resistance to ozone and sunlight.

EPDM Rubber

EPDM rubber is a synthetic elastomer that has excellent resistance to weathering, ozone, and UV radiation. It is available in different grades such as peroxide cured, sulfur cured, and high-temperature.

Advantages

Good weatherability, good low-temperature performance, good chemical resistance, good electrical insulation, good abrasion resistance, good ozone resistance.

Disadvantages

Poor high-temperature resistance, poor resistance to oils and fuels, poor tear strength.

Fluorine Rubber™

Fluorine rubber™, also known as FKM, is a synthetic rubber that has excellent chemical resistance and high-temperature resistance. It is often used in demanding applications such as chemical processing and oil and gas industries.

Advantages

Excellent chemical resistance, excellent high-temperature resistance, good electrical insulation, good compression set, low gas permeability.

Disadvantages

High cost compared to other rubber materials, limited color options.

Our Large Selection of Silicone Rubber Molding Post-processing

At GPMFG, we offer a wide range of post-processing options for silicone rubber molding, including surface treatments, coatings, printing, laser marking, and pad printing. We also offer secondary operations such as component assembly and testing to complete the full production process. Our post-processing options provide customers with personalized solutions that meet their unique product needs and specifications while ensuring that the final product meets strict quality standards.

Pad printing

Pad printing is a popular printing technique used to transfer 2D images onto 3D objects via a silicone rubber pad. Silicone rubber molding is the process of creating a custom-made silicone rubber pad that makes contact with the printing plate and transfers the image to the desired substrate.

Burnishing

Burnishing is a finishing technique used on silicone rubber molds to smooth and polish the surface. This process involves using a smooth and hard object, such as a burnishing tool, to rub and compress the surface of the mold to create a glossy and uniform finish.

Painting

Painting in silicone rubber molding is a service that allows our clients to add vibrant color to their rubber components. After molding and curing, the silicone parts are painted with a custom color or design of choice using specialized paints and techniques. This service is ideal for creating distinctive, eye-catching rubber components that stand out from the rest.

Bonding

Bonding is a technique commonly used in silicone rubber molding to join two separate components together. This process involves applying a layer of adhesive material to both surfaces and then pressing them together to create a strong bond. Bonding is especially useful when creating complex components that require multiple parts to be joined together.

Why choose GPMFG as your preferred Silicone Rubber Molding service provider

As your preferred silicone molding provider, we offer value-added services including prototyping, cleanroom assembly, multi-material/multi-shot molding. Unique chromatography product design enhances purification, while LSR capabilities enable cost-friendly manufacturing of quality medical silicone parts. Rigorous quality processes and micro mold plastic selection allow custom solutions, guaranteed quality products, and short lead times.

- Value-added services: Prototyping, mold-making, packaging, and multi-material molding.

- Process chromatography: Efficient purification process and bioprocessing applications.

- Competitive prices: Advanced molding technology and multi-component production.

- Custom solutions: Design verification, mold design, and prototyping.

- Guaranteed quality: Low defect rates and high-quality materials and methods.

- Short lead time: High-power vision system for quick and efficient production.

Professional Silicone Rubber Molding Services To Make You Worry-Free

20+ people design & technology team

With an average of more than 15 years of experience in die casting technology, our team can handle any sophisticated design and provide a feasible solution that exceeds expectations.

Advanced Silicone Molding technology

Our advanced silicone molding technology allows us to easily handle projects of all sizes and complexities with a tolerance of ±0.005mm.

Free of Flash

Flash is removed during high precision production and strict quality control tests, ensuring our silicone molded parts meet flash tolerances between 0mm and 0.03mm.

Cost-competitive manufacturing

Our cost-competitive manufacturing services are enabled by employing optimized DFM standards for efficient and affordable production.

Facilitate On-Demand Manufacturing for Quicker and Simpler Results.

Once you are prepared to commence your upcoming venture, you can effortlessly upload your 2D/3D CAD design files and our team of engineers will promptly provide you with a quotation within 24 hours.

- 10 to 500,000 parts available

- Save 50-70% costs

- 40% reduction in delivery time

Jacob Deng

- jacob@gainpower-mfg.com

- +86 132 1516 3182

Address

-

NO 1,HengZeng road,XinAn community,ChangAn town,

DongGuan City,GuangDong,China(Post code:523882)