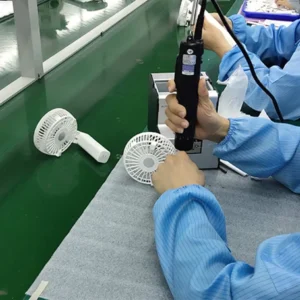

One-Stop Solution & Full Manufacturing Capabilities

We offer advanced technology for lightning-fast, high-quality prototype manufacturing and production. Enjoy superior results and fast delivery. Low volume of production available, NDA(non disclosure agreement) availible, ROHS availible.

Full Process

Prototype&Mass production

Mold Manufacturing Service

Chinese LKM ,DME,HASCO standard components availible

- Mold follow,Mold Design, Mold Manufacturing

- Prototype Molds,low life Molds up to 1 Million-shots Molds

- Single Cavity Molds, Multi Cavity Molds,Family Molds

- Plastic Injection Molds, Die Casting Molds

Plastic Injection Molding Service

Tolerance obey ISO2768,ROHS availible

- Insert Molding, Overmolding

- 2-shot molding,3-shot molding

- A variety of Selectable Plastic Resin

- Post processes: Paiting, print, plating, Assembly, etc

Die Casting Service

Tolerance obey ISO2768,ROHS availible

- AL Die Casting, Zinc Die Casting

- CNC Machining

- Air tightness test, Flaw detection test,etc

- Post processes: Passivation, Powder spray,plating,etc

Parts CNC Mahining Service

Tolerance obey ISO2768,ROHS availible

- 3-5 Axis CNC Machining

- CNC Turning

- CNC Metal parts:Steel, Aluminum alloy,Bronze,Brass,Copper,etc

- CNC Plastic parts:POM, ABS, NYLON, etc

Silicone Rubber Molding Service

ROHS availible

- Silicone rubber compression molding

- Silicone rubber injection molding

- A variety of Selectable Hardness SHORE-A

- Post processes: Paiting, print, etc and Fatigue test

Customized service

part manufacturing solutions

- Part Manufacturing Solutions

- Rapid Prototyping Service

- Low Volume Manufacturing Service

- Mass Production Service

- Surface Finish Services

- OEM/Assembly Service

Rapid Prototyping Service

Save your money during products test stage

- CNC Machining for Metal parts & plastic parts

- Injection Molding via Rapid Molds

- Vacuum Casting via Silicone Molds

- 3D Print for Metal parts & plastic parts

Low Volume Manufacturing Service

Reduce your inventory At the beginning of the products sales

- Short parts manufacturing time, 3-10 days

- Match with The market performance of your products for Years

- Years of Molds/Fixtures maintenance without fee

- Molds/Fixtures and Processes improvement to optimize products

Mass Production Service

Delivery date on time and Quality guarantee

- Weekly progress report in your control

- Raw material Composition provided

- FAI and ROHS reports for each shipment

- Products test reports available if need

Surface Finish Services

A variety of Surface finish.For Plastic,Metal and Silicone parts

- Upgrade the visual effects of your products

- Improve the touch of the products

- Prolong products life

- Meet the special performance of the products

OEM Service

NDA(non disclosure agreement) and Your Authorization is necessary

- Protect your copyright

- 30% Less Than Your Local Prices

- Full resources for your products

- Customized product testing standards

Final Products