Efficient and profitable parts mass production

Our high-volume manufacturing services cover a wide range of processes to meet your production needs. With over 30 plastics available for injection molding, we can achieve precise tolerances down to ±0.01″. In addition to injection molding, we offer other options such as metal injection molding, die casting, and silicone rubber molding, and our diverse production processes allow us to deliver thousands to millions of complex precision parts each year, quickly and accurately.

- Free DFM Feedback With Your Quote

- Save 40-60% costs

- 40% reduction in delivery time

Reliable mass production services - stable & Affordable

At GPMFG, we leverage cutting-edge manufacturing technology to optimize processes and provide competitive market pricing. Our commitment to quality ensures that our products are consistently of the highest standards, free from human error. By partnering with us, you can reduce your costs by up to 40-60%.

Our capabilities include mass-producing parts with tight tolerances and exacting precision requirements, and manufacturing parts of any complexity, shape, or geometry. We cater to all industries and materials, and our customizations are limitless. Choose GPMFG for high-volume orders and unparalleled manufacturing expertise.

- 30% less than local prices

- 100+ materials in stock

- ±0.001mm tolerance

Our Excellent mass productionServices

With our range of equipment and corresponding technologies, we are equipped to provide tailored solutions for your distinct parts requirements.

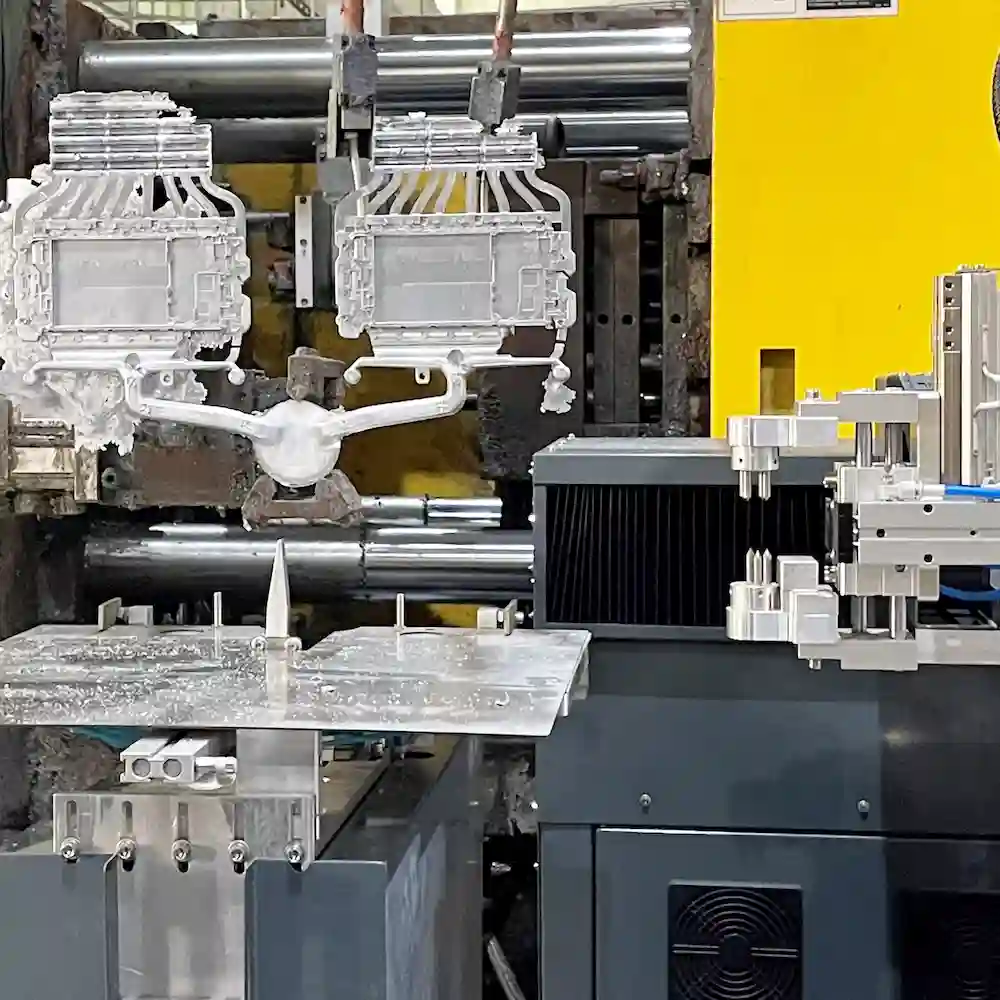

Die Casting

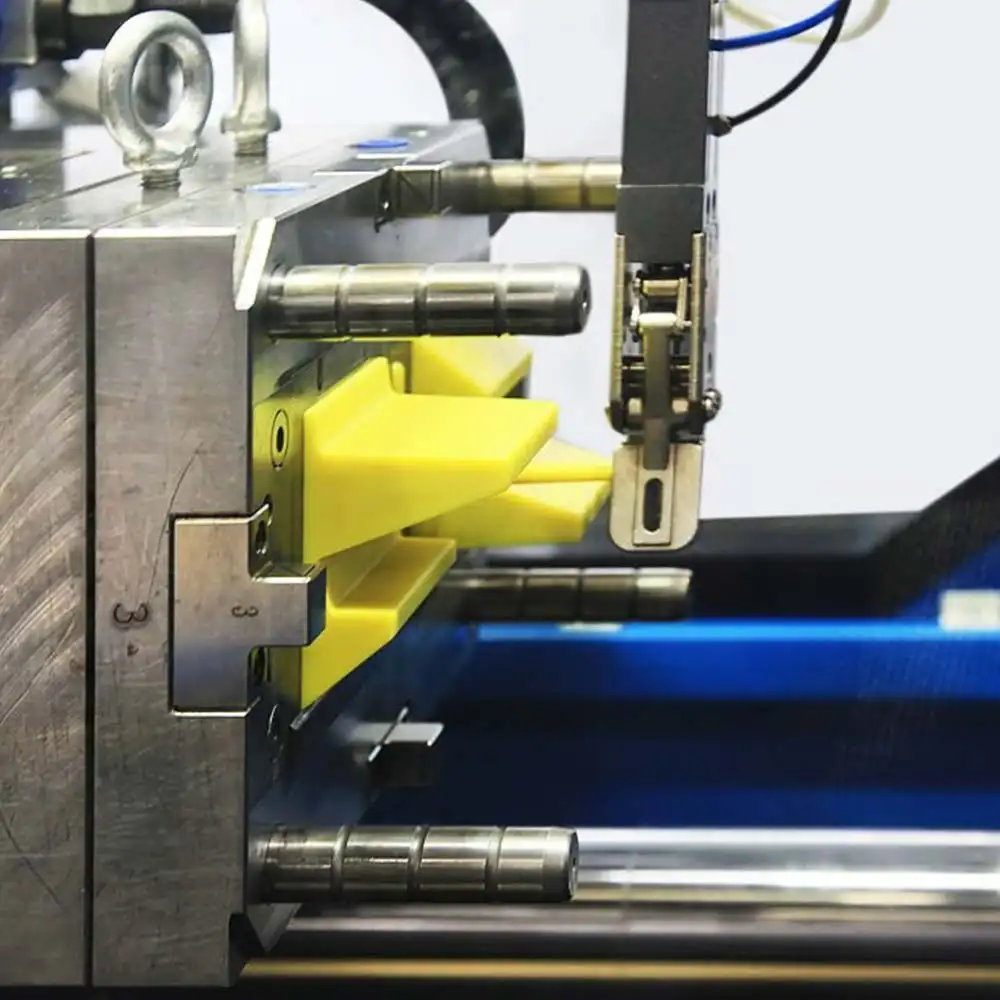

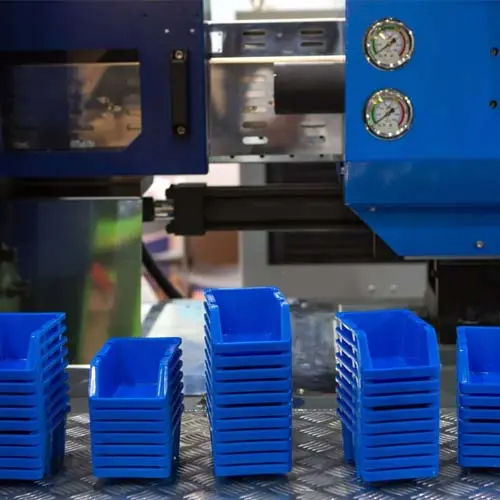

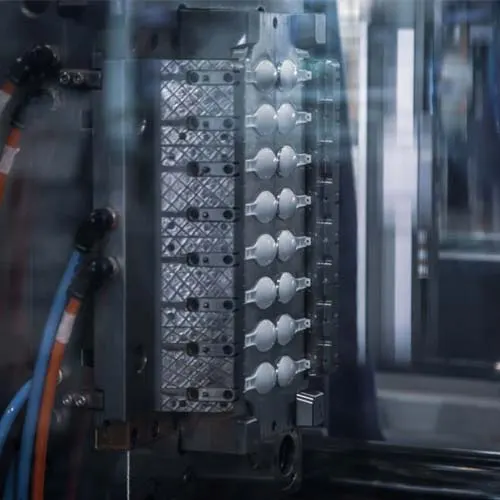

injection molding

CNC Machining

SILICONE RUBBER MOLDING

Our On-Demand Manufacturing capabilities

Our prototyping capabilities are flexible and adaptable, allowing us to create a wide range of prototypes for different industries and applications.

mass production Injection Molding

Our rapid prototyping materials are designed to meet the demands of modern product development. From flexible, rubber-like materials to rigid, high-strength plastics, we’ve got you covered. Our materials are compatible with a range of all technologies, making it easy to create the perfect prototype for your needs.

| Standard capabilities | Description |

| Mold cavity tolerances | ±0.05 mm |

| Standard lead time | 15 business days or less |

| Part to part repeatability | ±0.1 mm |

| Production grade | 1-100,000 cycles |

mass production Die Casting

Our rapid prototyping materials are designed to meet the demands of modern product development. From flexible, rubber-like materials to rigid, high-strength plastics, we’ve got you covered. Our materials are compatible with a range of all technologies, making it easy to create the perfect prototype for your needs.

| Dimension | Standards |

| Minimum part weight | 0.017 kg |

| Maximum part weight | 12 kg |

| Minimum part size | ∅ 17 mm × 4 mm |

| Maximum part size | 400 mm × 300 mm |

| Minimum wall thickness | 0.5 mm |

| Maximum wall thickness | 12.7 mm |

| Tolerance class for casting | ISO 8062 ST5 |

| Minimum possible batch | 1000 pcs |

mass production silicone rubber Molding

Our rapid prototyping materials are designed to meet the demands of modern product development. From flexible, rubber-like materials to rigid, high-strength plastics, we’ve got you covered. Our materials are compatible with a range of all technologies, making it easy to create the perfect prototype for your needs.

Material | Solid silicone rubber |

Process | Compression Molding |

Environmental safety | Environmental Class |

Application | Electronics and Electrical Industry,etc |

Product Tolerance | Tightest ±0.05 mm,Recommend ±0.1 mm |

Product Thickness | Avarage 3.0 mm,Min. 0.4 mm,Max. 15-20 mm and 30mm for ball |

Assembly Gap | 0.2-0.5 mm |

Shrinkage | 1.03 |

Cutting Method | Tear Lines Made In Mold |

Pull Off Flash Material | |

Temperature Range | Operating Temperature: -30° C to +180° C |

Storage Temperature: -42° C to 250° Cs |

mass production CNC Machining

When it comes to quick prototyping of plastic and metal parts, CNC machining tops the list as the ideal production method. We’re proud to say that our services can create all the prototypes you require with the utmost precision and detail, and within a remarkably short timeframe.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm (+/- 0.001 inch) |

| Hole diameters (not reamed) | +/- 0.025 mm (+/- 0.001 inch) |

| Shaft diameters | +/- 0.025 mm (+/- 0.001 inch) |

| Part size limit | 950 * 550 * 480 mm(37.0 * 21.5 * 18.5 inch) |

Rich choice of materials

Whether you’re a designer, engineer, or inventor, our materials will help you bring your ideas to life with precision and ease. Plus, our materials are affordable, so you can iterate and perfect your designs without breaking the bank.

- ABS(Acrylonitrile Butadiene Styrene)

- ABS+PC(ABS + Polycarbonate Alloy)

- HDPE(High Density Polyethylene)

- HIPS(High Impact Polyethylene)

- LCP (Liquid Crystal Polymer)

- Nylon 6(Polyamide 6)

- Nylon 11(Polyamide 11)

- Nylon 66(Polyamide 66)

- PBT(Polybutylene Terepthalate)

- PC(Polycarbonate)

- PE(Polyethylene)

- PEI(Polyetherimid)

- PET (Polyethylene Terepthalate)

- PMMA(Acrylic)

- POM(Acetal)

- PP(Polypropylene)

- PPA (Polyphthalamide)

- PPS(Polyphenylene Sulfide)

- PS(Polystyrene Crystal)

- SAN(Styrene Acrylonitrile)

- LDPE(Low Density Polyethylene)

- PVC(Polyvinylchloride)

- TPR(Thermo Plastic Rubber)

- TPU(Thermoplastic Polyurethane Elastomer)

- ALUMINUM ALLOY A380

- MAGNESIUM ALLOY AZ91D

- ZINC ALLOY ZAMAK#3

- ZINC ALLOY ZAMAK#5

Benefits of Mass production

At GPMFG, we focus on high-volume production to meet our customers’ needs. Our high-volume production process is optimized for efficiency and quality control, allowing us to produce large volumes of parts quickly and reliably while maintaining consistency and meeting strict deadlines. This approach ensures that our customers can meet their production goals, reduce costs and maximize profits.

Lower unit costs

Large-scale production allows for economies of scale, which means that unit costs decrease as the number of items produced increases. This is particularly beneficial for companies that produce large quantities of goods, as significant cost savings of up to 50% can be achieved.

Faster production

Mass production is highly optimized for efficiency and speed, which results in faster production times than small batch manufacturing. This is especially true for products that require a high degree of automation, such as consumer electronics.

Consistency & quality control

The use of automated production processes and stringent quality control measures ensure consistent product quality in high volumes. Large-scale manufacturing minimizes errors in production, ensuring that the final product meets customer expectations and reduces the likelihood of product recalls.

Shorter lead times

With large quantities of products produced, companies can maintain sufficient inventory levels to meet customer demand. This allows manufacturers to respond quickly to large orders and reduce lead times.

High quality & consistent parts

High-Quality parts with consistency beyond your expectations

GPMFG is your best choice for On-demand Production Solutions

With our prototyping capabilities, you can tailor your product to meet your exact specifications and design needs.

Fast Turnaround Time

We understand that time is of the essence when it comes to prototyping. That's why we offer some of the fastest turnaround times in the industry. With our advanced technology and expertise, we can deliver your prototypes as quickly as 24-48 hours.

High-Quality Prototypes

At GPMFG, we are committed to delivering only the highest quality prototypes. Whether you need metal or plastic parts, we use the latest technology and the best materials to ensure that your prototypes meet your exact specifications.

Affordable Prices

We believe that everyone should have access to high-quality prototypes at an affordable price. That's why we offer some of the most competitive prices in the industry. With our streamlined process and state-of-the-art technology, we can keep our costs low without sacrificing quality.

High-Quality Results

At GPMFG, we are committed to delivering high-quality results that meet your exact specifications. We use only the best materials and the latest manufacturing techniques to ensure that your prototypes are durable, functional, and visually appealing.

On-Demand Production

GPMFG offers an on-demand production service that is one of its top features. This service enables us to cater to the requirements of any client, be it a single prototype, a small batch, or a large-scale production order.

Diversified Processing Technology

At GPMFG, we pride ourselves on being a comprehensive supplier with cutting-edge technology to produce parts at scale. Our expertise includes CNC machining, metal and plastic injection molding, die casting, metal stamping, silicone rubber molding, and other manufacturing processes.

Comprehensive Surface Finishing Tech

We understand that the appearance of your prototypes is just as important as their functionality. That's why we offer a range of surface finishing options, including painting, anodizing, and polishing, to ensure that your prototypes look as good as they perform.

Experienced Team

Our team of engineers and technicians has years of experience in prototyping and manufacturing. We work closely with you to understand your needs and ensure that your prototypes meet your exact specifications.

Immediately start the next project and occupy the market

mass production Guide - FAQ

1. What is Mass production?

Mass production refers to the production of large quantities of products, often in the thousands or even millions, at a consistent rate. This type of manufacturing process is designed to produce large quantities of products quickly and efficiently, and is typically used in the mass production of consumer goods, electronics, automotive parts and other items. High-volume manufacturing typically requires significant upfront investment in tools, equipment and facilities, and may require longer lead times than small-volume manufacturing. However, once established, it can provide significant cost savings and efficiency gains compared to low-volume manufacturing processes.

2. What are the advantages of Mass production?

- Cost reduction:

The initial cost of tooling and setup can be high, but once the tooling is in place, producing large quantities of parts becomes more cost-effective than other manufacturing processes. - Consistency and accuracy:

Plastic injection molding allows for highly consistent and precise production, which ensures that every part produced is of high quality with minimal variation in dimensions and other specifications. - Production speed:

Injection molding can produce parts at high speeds, with some machines capable of producing thousands of parts per hour, resulting in fast turnaround times and high volume production. - Versatility:

Batch production can be used to produce a wide range of products, including small and complex parts, large and complex parts, and parts with a variety of shapes and sizes. - Waste reduction:

Mass production helps reduce waste because the process is highly controlled and standardized. This means that the amount of material used can be optimized and any waste can be recycled or reused in the production process.

3. What are the disadvantages of Mass production?

Mass production can be defined as the use of standardized processes and the manufacture of large quantities of identical products by machinery. While it has many advantages, such as increased efficiency and reduced costs, there are some disadvantages to mass production in different molding processes.

- Initial setup costs:

Mass production requires significant initial setup costs, such as tooling, dies and equipment. This can be a significant investment for manufacturers, especially for smaller companies. - Limited flexibility:

Once a mold is created, it is difficult to make changes to the design. This means that if the design needs to be modified or updated, a new mold may need to be created, which can be both time-consuming and expensive. - Reliance on skilled labor:

Some molding processes require highly skilled workers to operate the machines and ensure that the product is produced to the required specifications. This can be a disadvantage if some manufacturers lack skilled labor.

4. Is mass production cheap?

In terms of unit cost, high-volume production is usually cheaper than producing the same product in small batches. This is due to economies of scale, where the fixed costs of production, such as tooling and setup costs, can be spread over a larger number of units.

For example, if it costs $1.00 to produce a single part using a less efficient method, it will cost $10,000 to produce 10,000 parts. However, investing $3,000 in a 4-cavity mold may seem expensive, but the cost per unit of production can clearly be reduced to $0.25, producing 10,000 parts for only $2,500, which ends up being a cost savings of $4,500. ($3,000 for the mold + $2,500 for the parts)

It is worth noting that there are other costs associated with mass production, such as tooling setup costs, machine maintenance and labor costs. These costs may vary depending on the specific production process and the product being produced. Therefore , each scenario must be evaluated individually to determine if mass production is cost effective.

5. How long does it take to mass produce a product?

Depending on the complexity of the product, the size of the production run, and the efficiency of the production process, the time required to mass produce a product can vary greatly. In general, production of simple products that require only basic assembly can be completed relatively quickly in a few days or weeks. However, production of more complex products (e.g., electronics or machinery) can take several months or even longer.

- Design and Prototyping:

This phase involves creating a design for the product and building a prototype to test it. Depending on the complexity of the product, this phase can take anywhere from a few days to several months. - Tools and preparation:

Once the design is complete, the next step is to create the molds and tools needed for production. This can take anywhere from a few weeks to a few months, depending on the complexity of the product and the availability of resources. - Raw material acquisition:

Raw materials are required to produce the product, and the necessary materials in the required quantities can be obtained in half a week. - Production:

The actual production of the product can take anywhere from a few days to a few weeks, depending on the quantity and complexity of the product. - Quality control:

After the products are manufactured, quality control checks must be performed to ensure that they meet the required specifications. The time required for quality control checks may vary, but usually takes a few days to a week. - Packaging and shipping:

Once the products have passed quality control, they are packaged and shipped to the desired destination. This can take anywhere from a few days to a few weeks, depending on the shipping method and distance.

6. What do I need to pay attention to for mass production?

- Proper programming of the machine: It is important to ensure that the machine is properly programmed for the specific part being produced. Any errors in programming can lead to part failures or inconsistencies.

- Assembling an efficient production process: Designing an efficient production process can help reduce costs and increase productivity. This may involve streamlining workflow, optimizing the use of materials and equipment, and minimizing waste.

- Part accuracy and consistency: Achieving a high level of accuracy and consistency in the parts produced is critical, especially where tight tolerances are required. This can be achieved through careful selection of materials and equipment and the implementation of strict quality control processes.

- Schedule or Turnaround Time: It is important to establish realistic schedules or turnaround times for production, taking into account any potential delays or setbacks that may occur. This helps ensure that the project stays on schedule and meets deadlines.

- Good quality control processes: Quality control is critical to ensure that parts meet the required standards. This may involve visual inspection, dimensional measurements and testing to ensure the part is fit for purpose.

- Achieving the tight tolerances required: Achieving tight tolerances can be challenging, especially in small production runs. It may be necessary to invest in specialized equipment or processes to achieve the required level of accuracy.

- Safety and durability of the final parts produced: This may involve selecting materials suitable for the intended application, as well as testing and validating parts to ensure they are safe and reliable.

7. Does GP MFG provide post mass production assembly services?

Yes! GP MFG offers parts assembly as part of our on-demand service. After we produce your bulk order, we can set up and customize your assembly line and deliver your ready final parts with a quick turnaround.

Our services include CMM inspection and quality testing of all assembled products.

- What is Mass production?

- What are the advantages of Mass production?

- What are the disadvantages of Mass production?

- Is mass production cheap?

- How long does it take to mass produce a product?

- What do I need to pay attention to for mass production?

- Does GP MFG provide post mass production assembly services?