Sourcing custom Medical parts

GPMFG has over a decade of experience and a successful history of providing diversified precision molding services specifically for the medical industry. Our services include the manufacture of components for therapeutic devices, precision instruments, specialized instruments and other essential tools. Our team is dedicated to producing reliable and life-saving precision medical prototypes and products that meet precise specifications and tight tolerances. We prioritize regular communication and on-time delivery to maintain exacting standards.

- Tight tolerances & 2D drawings accepted

- Steel tooling with T1 samples as fast as 10 days

- Instant pricing & DFM

Quality Certifications

We are ISO 9001, ISO 14001 and ISO 13458 certified. We also provide comprehensive quality documentation CMM inspection reports, material certifications, material and process lot traceability, full size reports, inspection reports and hardware certificates.

Comprehensive machining capabilities

GP MFG offers one stop service for manufacturing molded parts, whether plastic or metal. Our solutions are both cost effective and top quality and include mold making, injection molding, die casting, silicone rubber molding, rapid prototyping, and low volume manufacturing for all your molding needs.

Fast Turnaround Time

Our state-of-the-art technology and efficient processes allow us to provide you with a perfect DMF report within an hour and parts that meet your specifications by the third day. Whether you need a few parts for prototyping or mass production. We are confident that our fast turnaround times will exceed your expectations and help you stay ahead of the competition.

High quality & consistent parts

High-Quality parts with consistency beyond your expectations

- Beauty equipment

- Handheld devices

- Fitness equipment

- Care equipment

- Blood glucose meters

- B-ultrasound detectors

- Medical monitor

- Ultrasonic equipment

Successful & efficient projects and reviews

Oxygen Cylinder

Process: injection molding>pad printing

Mold cavity:1+1

Cycle time:38s

Lead time:(10 days for 1st 5K)+(the lead time of material)

Customer Region: North America&EU

Material : PC , carbon black color

Plastic Knob

Process: injection molding> Rotary printing

Mold cavity:2

Cycle time:18s

Lead time:(10 days for 1st 5K)+(the lead time of material)

Customer Region: North America&EU

Material : PC , carbon black and gray color

Our Excellent High volume manufacturing Services

With our range of equipment and corresponding technologies, we are equipped to provide tailored solutions for your distinct parts requirements.

injection molding

Die Casting

SILICONE RUBBER MOLDING

CNC Machining

Prototyping & Production Solutions

As an injection molding manufacturer, we understand the importance of high-quality parts that meet your exact specifications. That’s why we offer comprehensive molded parts service to handle every step of the production process, from design to delivery.

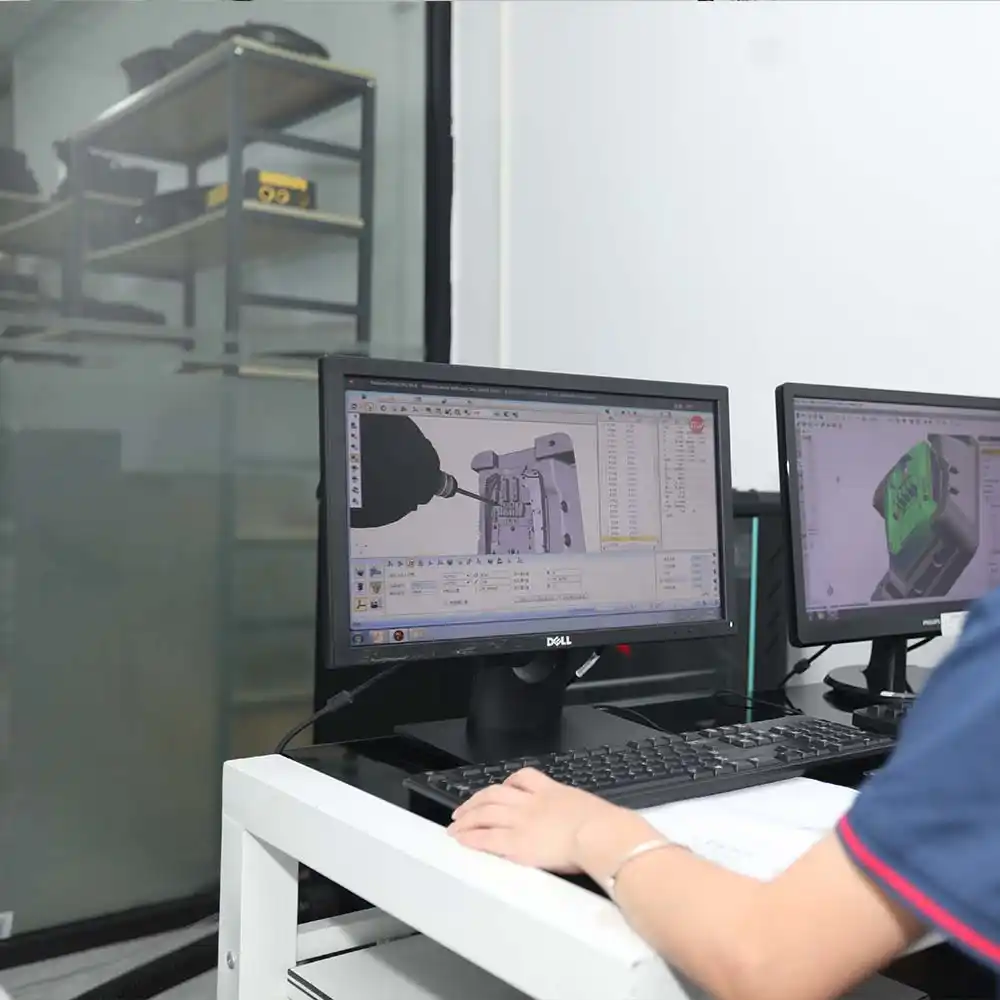

Design

We work with you to design your part using CAD software. This allows us to create a 3D model of your part and test it for manufacturability before we start the mold-making process.

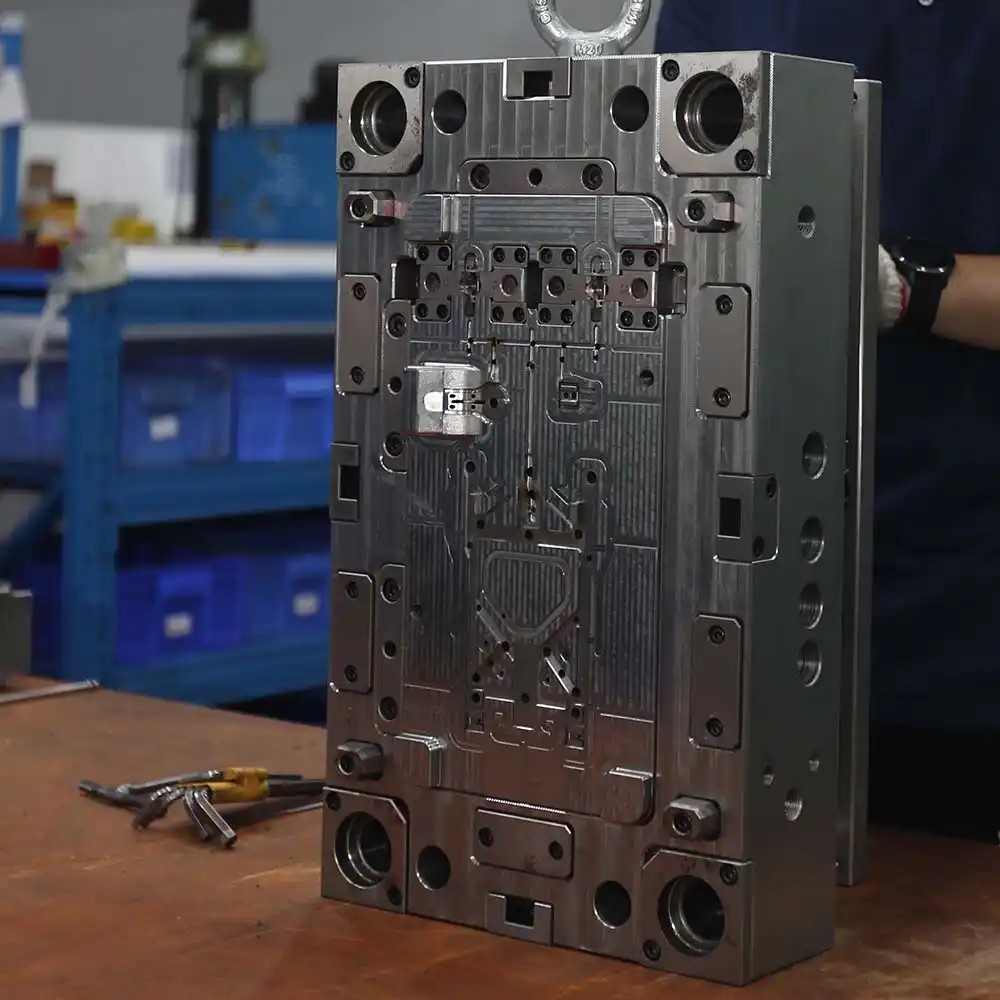

Mold-making

Once the product design is finalized, our team of mold designers and manufacturing experts use state-of-the-art equipment to create high-quality molds that meet the exacting standards of our customers. We use a variety of materials, including steel, aluminum, and others, to ensure that the molds are durable, reliable, and cost-effective.

Mass production

With our advanced equipment, we can mass produce molded parts to your exact specifications using a variety of processing methods such as injection molding, die-casting, and CNC machining.

Finishing

After your parts are molded, we provide finishing services such as painting, plating, and assembly to ensure that your parts are ready for use right out of the box.

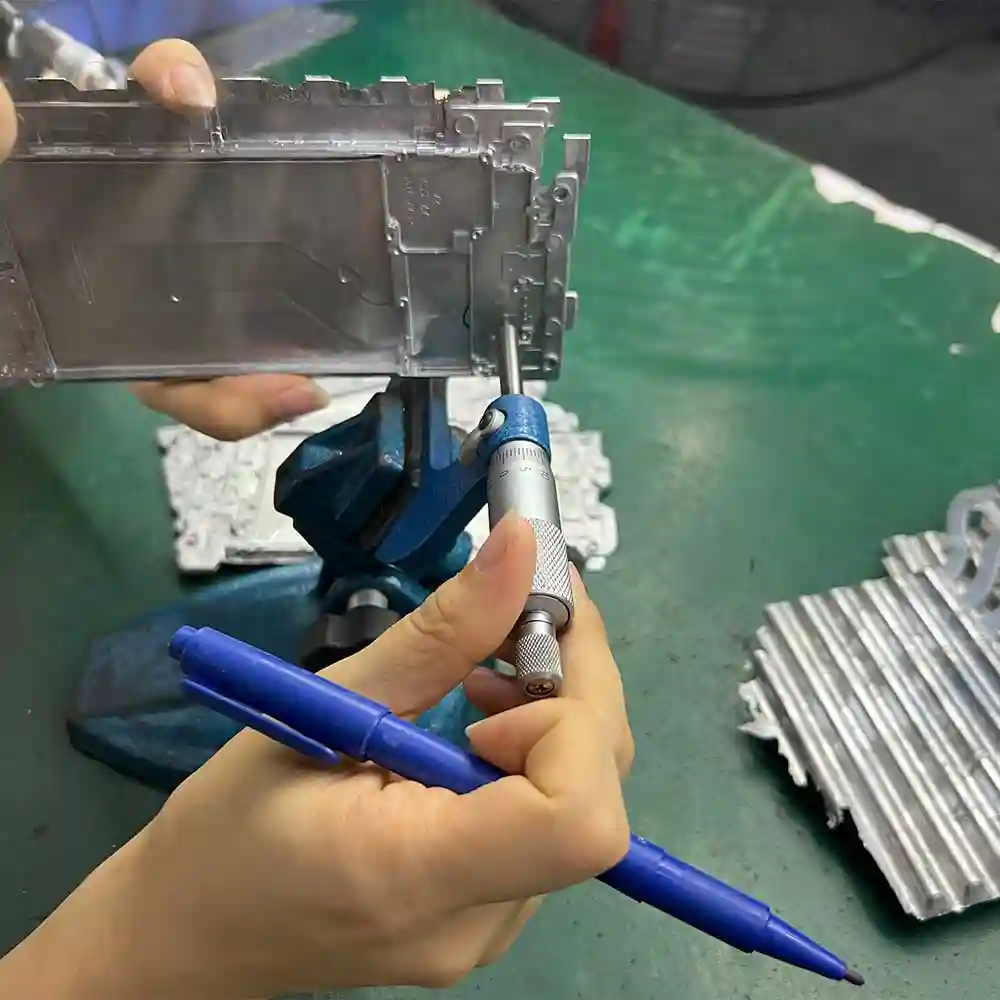

Quality Control

Throughout the production process, we use advanced quality control measures to ensure that our products meet the highest standards of quality and reliability. We use a variety of testing methods, including dimensional inspection, material testing, and functional testing, to ensure that the parts are defect-free and meet our customers’ specifications.

Packaging and delivery

Finally, we carefully package your parts according to your requirements and ship them to your desired location, making sure they arrive on time and in perfect condition.

GP MFG is your best choice for On-demand Production Solutions

With our superior capabilities, you can tailor your product to meet your exact specifications and design needs.

Fast Turnaround Time

We understand that time is of the essence when it comes to prototyping. That's why we offer some of the fastest turnaround times in the industry. With our advanced technology and expertise, we can deliver your prototypes as quickly as 24-48 hours.

High-Quality Prototypes

At GP MFG, we are committed to delivering only the highest quality prototypes. Whether you need metal or plastic parts, we use the latest technology and the best materials to ensure that your prototypes meet your exact specifications.

Affordable Prices

We believe that everyone should have access to high-quality prototypes at an affordable price. That's why we offer some of the most competitive prices in the industry. With our streamlined process and state-of-the-art technology, we can keep our costs low without sacrificing quality.

High-Quality Results:

At GP MFG, we are committed to delivering high-quality results that meet your exact specifications. We use only the best materials and the latest manufacturing techniques to ensure that your prototypes are durable, functional, and visually appealing.

On-Demand Production

GP MFG offers an on-demand production service that is one of its top features. This service enables us to cater to the requirements of any client, be it a single prototype, a small batch, or a large-scale production order.

Diversified Processing Technology

At GP MFG, we pride ourselves on being a comprehensive supplier with cutting-edge technology to produce parts at scale. Our expertise includes CNC machining, metal and plastic injection molding, die casting, metal stamping, silicone rubber molding, and other manufacturing processes.

Comprehensive Surface Finishing Tech

We understand that the appearance of your prototypes is just as important as their functionality. That's why we offer a range of surface finishing options, including painting, anodizing, and polishing, to ensure that your prototypes look as good as they perform.

Experienced Team

Our team of engineers and technicians has years of experience in prototyping and manufacturing. We work closely with you to understand your needs and ensure that your prototypes meet your exact specifications.

Rich choice of materials

Whether you’re a designer, engineer, or inventor, our materials will help you bring your ideas to life with precision and ease. Plus, our materials are affordable, so you can iterate and perfect your designs without breaking the bank.

- ABS(Acrylonitrile Butadiene Styrene)

- ABS+PC(ABS + Polycarbonate Alloy)

- HDPE(High Density Polyethylene)

- HIPS(High Impact Polyethylene)

- LCP (Liquid Crystal Polymer)

- Nylon 6(Polyamide 6)

- Nylon 11(Polyamide 11)

- Nylon 66(Polyamide 66)

- PBT(Polybutylene Terepthalate)

- PC(Polycarbonate)

- PE(Polyethylene)

- PEI(Polyetherimid)

- PET (Polyethylene Terepthalate)

- PMMA(Acrylic)

- POM(Acetal)

- PP(Polypropylene)

- PPA (Polyphthalamide)

- PPS(Polyphenylene Sulfide)

- PS(Polystyrene Crystal)

- SAN(Styrene Acrylonitrile)

- LDPE(Low Density Polyethylene)

- PVC(Polyvinylchloride)

- TPR(Thermo Plastic Rubber)

- TPU(Thermoplastic Polyurethane Elastomer)

- ALUMINUM ALLOY A380

- MAGNESIUM ALLOY AZ91D

- ZINC ALLOY ZAMAK#3

- ZINC ALLOY ZAMAK#5

Available surface finishes

Surface treatment is an important aspect of electronic parts that improves the durability, functionality and appearance of the product and provides protection against corrosion and wear, increasing aesthetics and extending the life of the product.

Painting

Adding a coat of paint to molded products provides a decorative finish and improves their appearance. Different paint types are available.

Electroplating

This process deposits a thin layer of metal onto the molded product, improving its durability and corrosion resistance.

Anodizing

This technique increases the thickness of the natural oxide layer on aluminum parts, enhancing their resistance to wear, corrosion, and color fading.

Powder Coating

The process of applying a dry powder to the surface of a molded product creates a durable and attractive finish that is resistant to chipping and scratching.

Shot blasting

Abrasive particles are blasted onto the molded product’s surface to remove any imperfections, such as rough edges or burrs.

Polishing

The surface of the molded product is mechanically polished to create a smooth and glossy finish, improving its aesthetic appeal.

Facilitate On-Demand Manufacturing for Quicker and Simpler Results.

Once you are prepared to commence your upcoming venture, you can effortlessly upload your 2D/3D CAD design files and our team of engineers will promptly provide you with a quotation within 24 hours.

- 10 to 500,000 parts available

- Save 50-70% costs

- 40% reduction in delivery time

Jacob Deng

- jacob@gainpower-mfg.com

- +86 132 1516 3182

Address

- 1112,No. 6 HengCheng Road, Chang 'an Town, Dongguan City,China(523880)